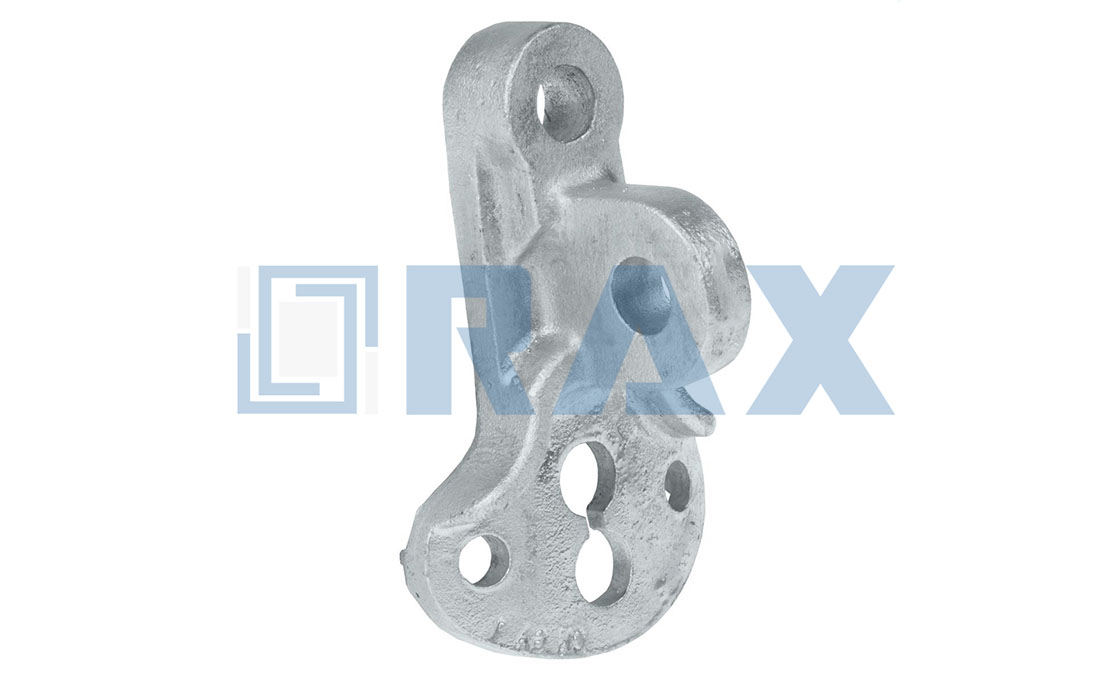

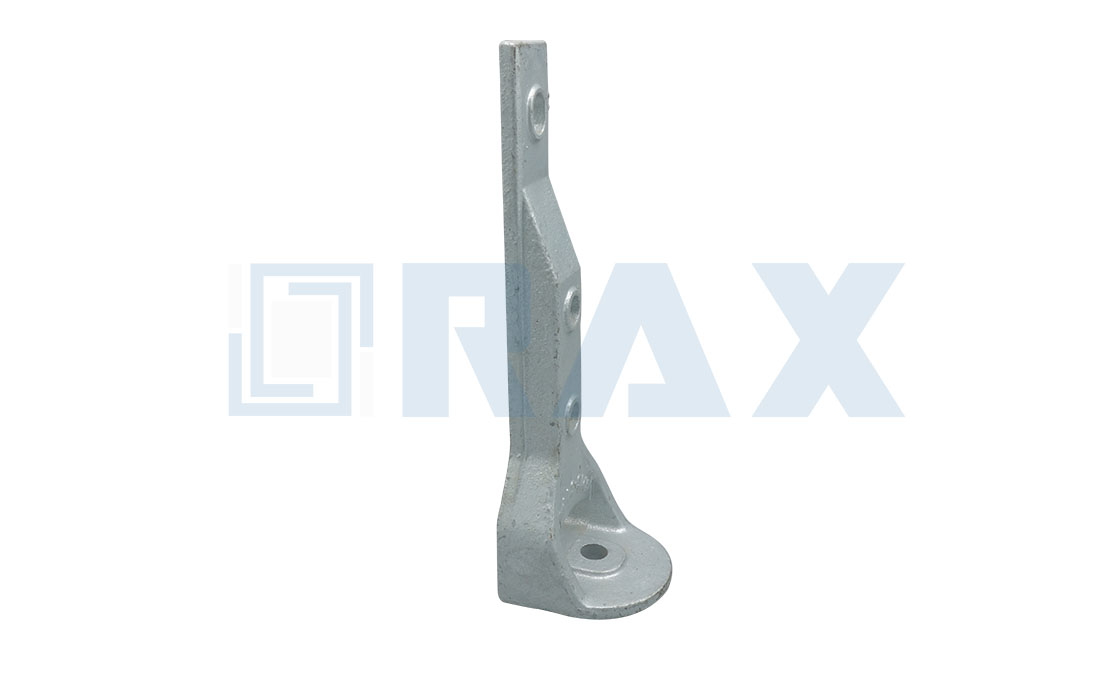

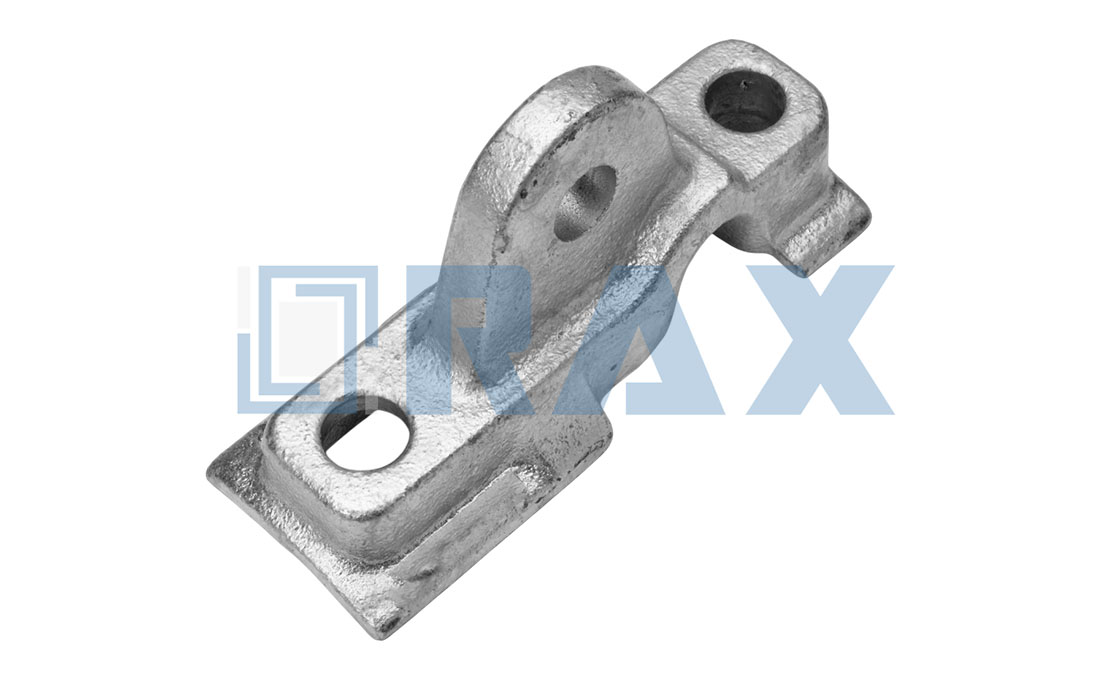

Pole Eye Plate

A Pole Eye Plate, also known as a guy attachment plate or pole mounting eye plate, is a heavy-duty steel fitting designed for securing guy wires and overhead lines to utility poles. This essential component features a forged eye integrated into a flat mounting plate, engineered to distribute loads evenly across the pole surface. The plate comes in various configurations including single eye, double eye, and triple eye designs, with working load ratings typically ranging from 30kN to 70kN depending on the model and application requirements.

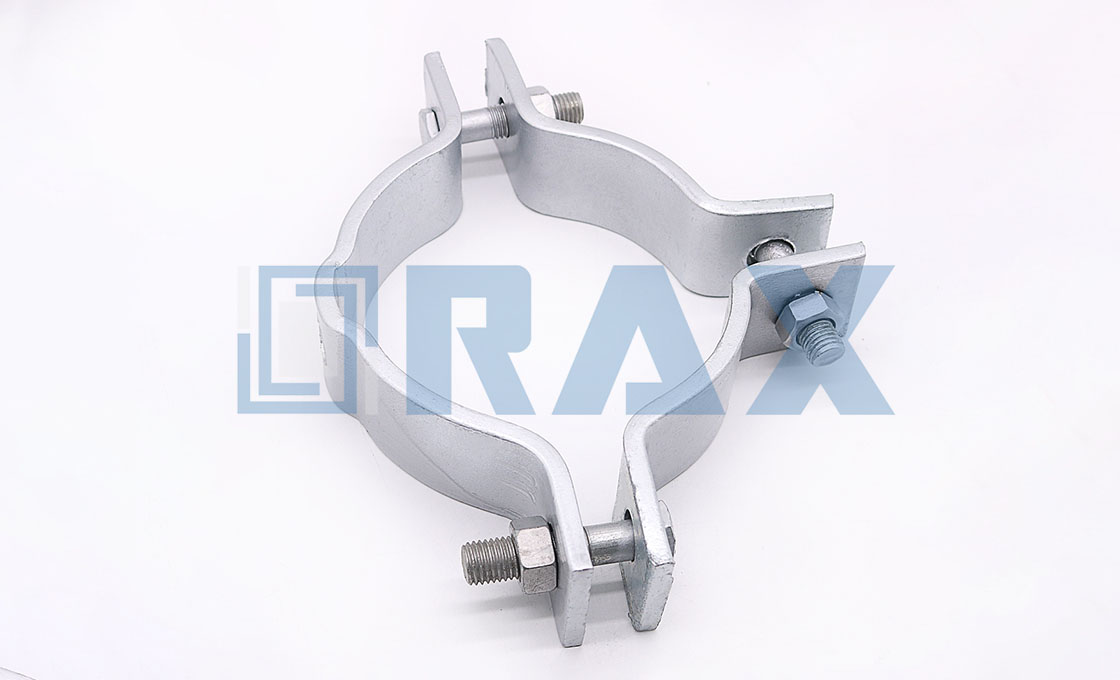

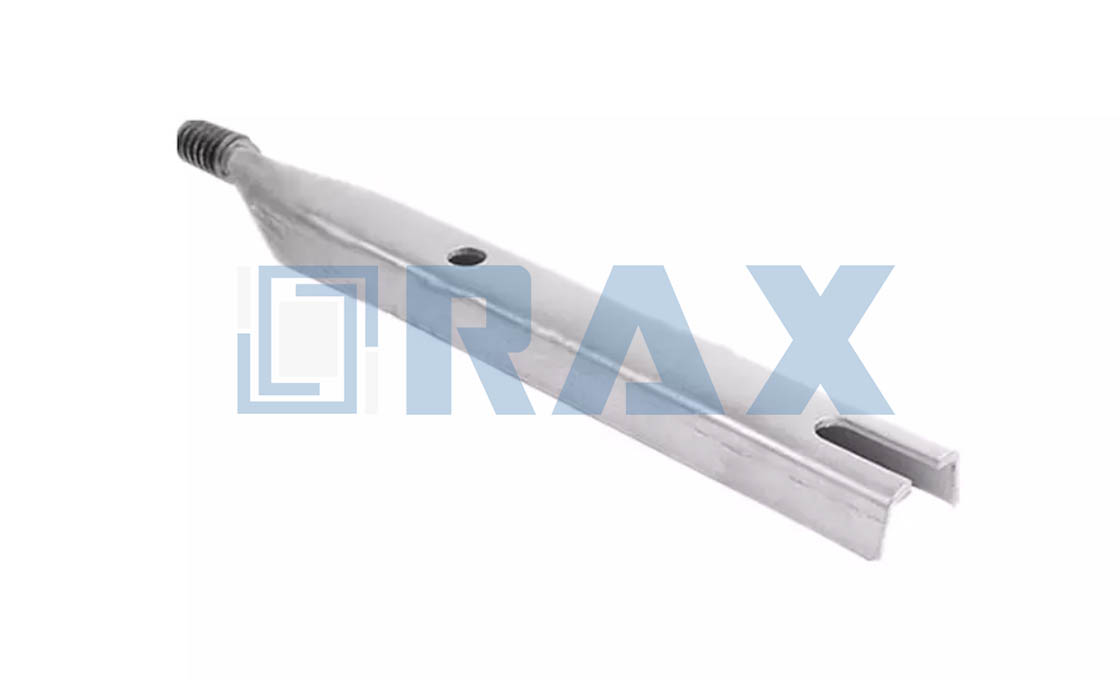

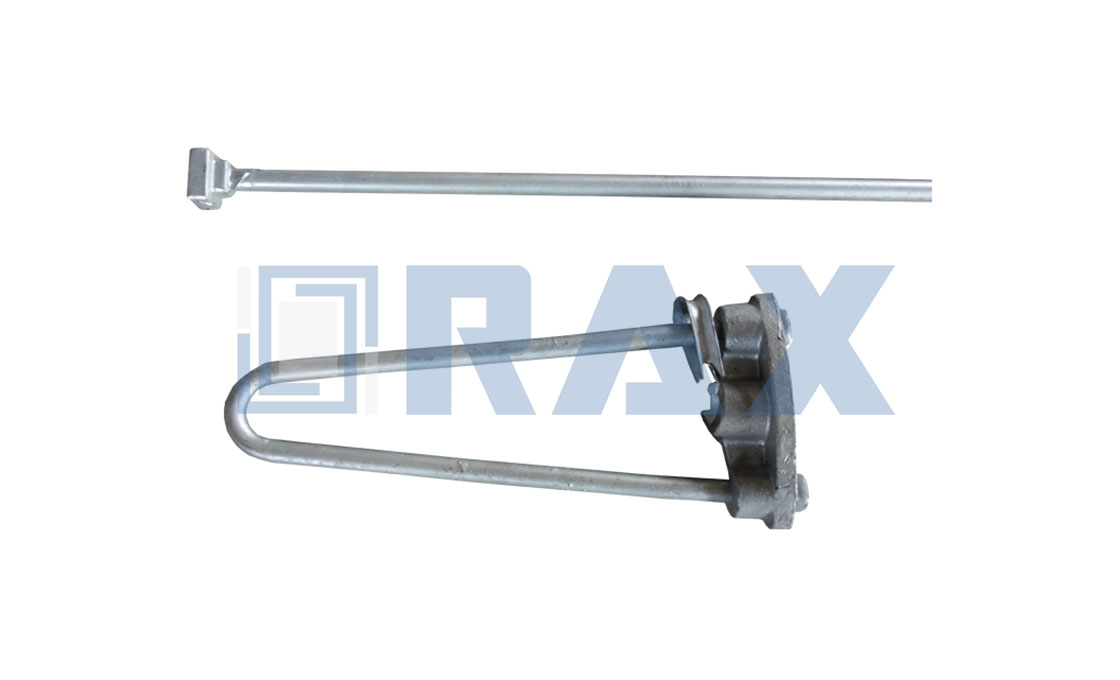

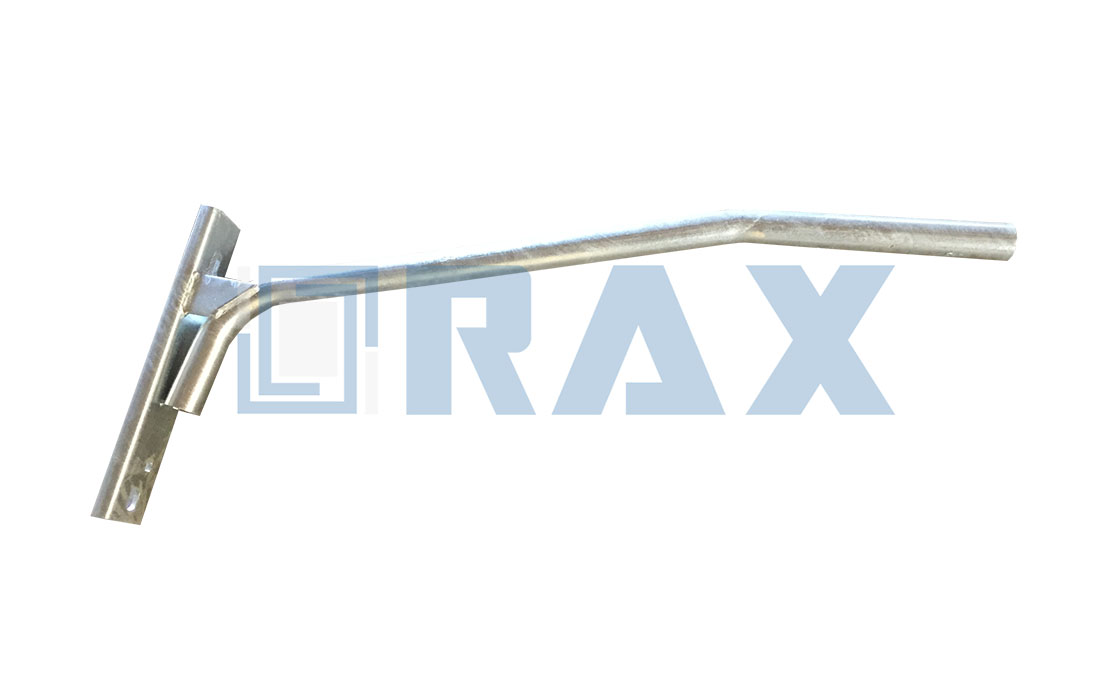

The eye plate serves as a critical anchor point for guy wires, messenger cables, and other overhead line components in utility infrastructure. Installation involves securing the plate to wooden poles using through bolts or lag screws, while concrete or steel pole installations typically use banding or specialized mounting hardware. The eye plate works in conjunction with thimble clevis, guy grips, and various attachment hardware to create secure termination points for overhead line systems, ensuring proper tension and support for utility networks.

Key Features:

- Material: Hot-dip galvanized steel (ASTM A153)

- Working load capacity: 30kN to 70kN

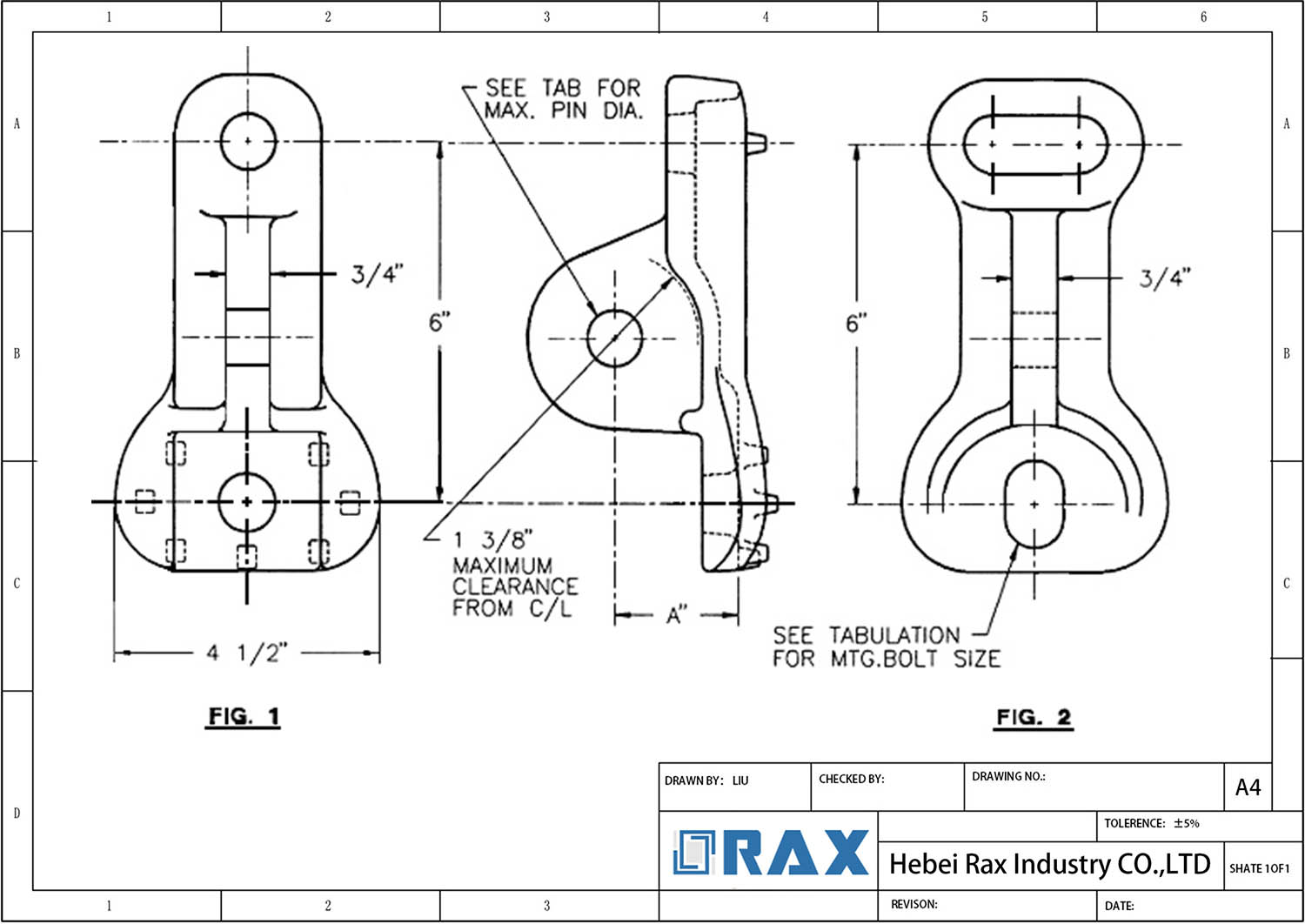

- Mounting holes: Pre-drilled for 5/8″ or 3/4″ through bolts

- Eye diameter: Compatible with standard 5/8″ and 3/4″ hardware

- Multiple eye configurations available (single, double, triple)

- Reinforced edge design for enhanced load distribution

Pole Eye Plate Drawing

Frequently Asked Questions

What are the different types of Pole Eye Plates available?

What are the different types of Pole Eye Plates available?

Pole Eye Plates come in three main configurations: single eye (30kN), double eye (50kN), and triple eye (70kN) designs. Each type features different mounting hole patterns and eye orientations to accommodate specific load requirements and installation configurations in utility applications.

What is the recommended installation torque for mounting bolts?

For wooden pole installations, 5/8″ through bolts should be torqued to 75 ft-lbs, while 3/4″ bolts require 100 ft-lbs. When using banding on concrete or steel poles, the band should be tensioned according to the manufacturer’s specifications.

How does the working load capacity vary with installation angle?

The working load capacity remains at 100% for angles up to 30° from vertical. For angles between 30° and 45°, capacity reduces to 85%. Installation angles greater than 45° are not recommended as they significantly reduce the plate’s load-bearing capability.

What are the spacing requirements between multiple eye plates?

Minimum vertical spacing between eye plates should be 12 inches for wooden poles and 18 inches for concrete poles. This ensures proper load distribution and prevents structural weakening of the pole.

Can Pole Eye Plates be used with different guy wire sizes?

Yes, the standard eye diameter accommodates guy wire sizes from 1/4″ to 1/2″ when used with appropriate thimble clevis hardware. For larger guy wire sizes up to 5/8″, specialized heavy-duty models are available.