Hex Bolt and Nut

Rax Industry hex bolt and nut also called galvanized bolts and nuts, hot dip galvanized bolt and nut, are used on power transmission lines, and overhead power lines. Rax Industry hex bolts and nuts fasten the pole line hardware or power line accessories.

Rax Industry hex bolt and nut are hot forged. The steel rod is heated to red-hot by the electric stove, then the red rods are punched into the hexagon head. The screw is made by a rolling machine.

The hex bolt and nut raw material is steel rod. Rax Industry doesn’t make the stainless steel hex bolt and nut. The popular diameter of the hex bolt and nut is 1/2’’, 5/8’’, and 3/4’’ while the thread is 100mm-400mm range.

The surface treatment for the hex bolt and nut is hot dip galvanization. The thickness reaches 43 microns according to standard ISO1461.

The packing for hex bolts and nuts is in cartons or woven bags. The cartons and bags are packed on the wooden pallet.

As a professional manufacturer, supplier, and exporter, Rax Industry can do the hex bolt and nut according to the customer’s design. Rax Industry can mark the logo on the Hex bolt and nut. If you have any inquiries, please contact us.

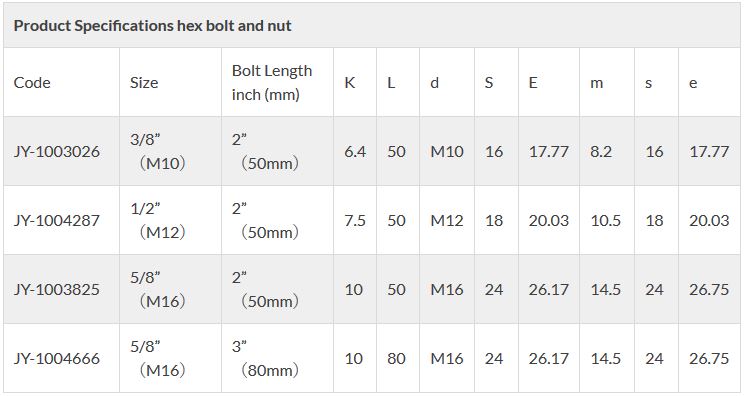

| Product Specifications hex bolt and nut | ||||||||||

| Code | Size | Bolt Length inch (mm) | K | L | d | S | E | m | s | e |

| JY-1003026 | 3/8”(M10) | 2”(50mm) | 6.4 | 50 | M10 | 16 | 17.77 | 8.2 | 16 | 17.77 |

| JY-1004287 | 1/2” (M12) | 2”(50mm) | 7.5 | 50 | M12 | 18 | 20.03 | 10.5 | 18 | 20.03 |

| JY-1003825 | 5/8” (M16) | 2”(50mm) | 10 | 50 | M16 | 24 | 26.17 | 14.5 | 24 | 26.75 |

| JY-1004666 | 5/8” (M16) | 3”(80mm) | 10 | 80 | M16 | 24 | 26.17 | 14.5 | 24 | 26.75 |

Hex Bolt and Nut: A Helpful Guide for Importers

- Chapter 1: What is a Hex Bolt and Nut?

- Chapter 2: Main Applications of Hex Bolt and Nut

- Chapter 3: Parts of Hex Bolt and Nut

- Chapter 4: Technical Specification of Hex Bolts and Nuts

- Chapter 5: Hex Bolts and Nuts Manufacturing Process

- Chapter 6: Step-by-step Hex Bolts and Nuts Installation Process

- Chapter 7: Frequently Asked Questions (FAQs)

- Chapter 8: Conclusion

Do you want to make a complete connection on pole line hardware and you do not know what to do?

Maybe you are trying to figure out the kind of tools you will require for this job, and everything is not clear.

Wonder no more as you are about to learn more about hex bolts and nuts to help you make the right decision.

What is a Hex Bolt and Nut?

To have a better understanding of what a hex bolt and nut is, I will have to break it down into two parts.

I will break it down into a bolt, and a nut then explains them differently.

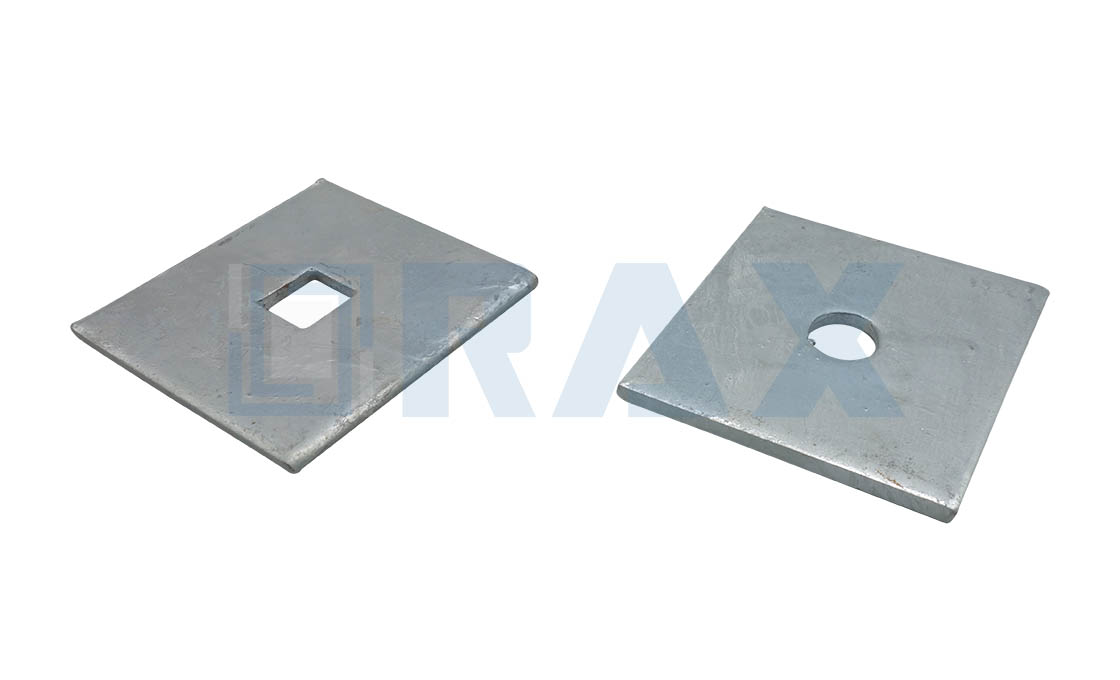

Hex bolt and nut

Hex bolt and nut

A bolt is a type of threaded fastener having a male thread on the exterior.

They are closely related and, in many cases, confused with screws.

It is, however, different from a screw as it is mainly used in conjunction with a bolt to fasten materials.

Nuts are types of fasteners with threaded holes and in most cases work in conjunction with a bolt.

The primary use is to fasten and hold different parts together by combining their threads through friction and other forces.

A hex bolt and nut are a combination of a bolt and a nut with a hexagonal shape.

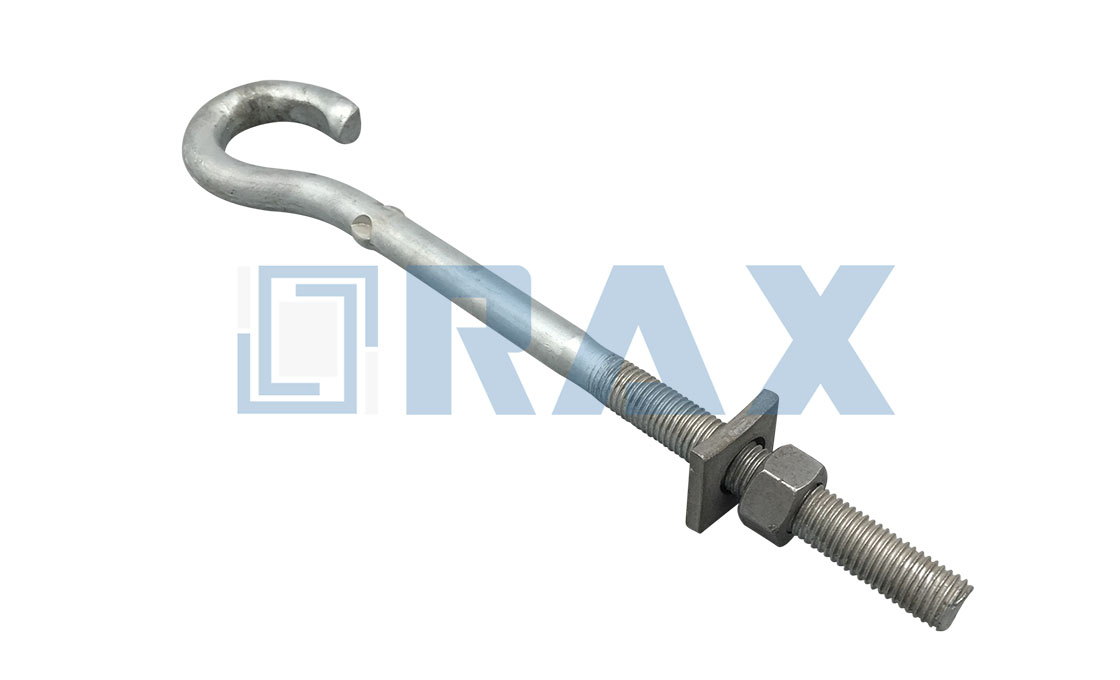

Bolt and nut

Bolt and nut

The head of the hex bolt has a hexagonal shape while the bolt also has a hexagonal shape.

This means that the bolts and the nut have six sides and they are driven using a wrench.

They are also known as hot-dip galvanized bolt and nut or galvanized bolts and nuts.

Main Applications of Hex Bolt and Nut

The primary function of a hex bolt and nut is to fasten and join two different parts together.

In pole line technology, they are standard on power line transmissions and overhead power lines.

They function as fasteners for accessories on the power lines and pole line hardware.

Parts of Hex Bolt and Nut

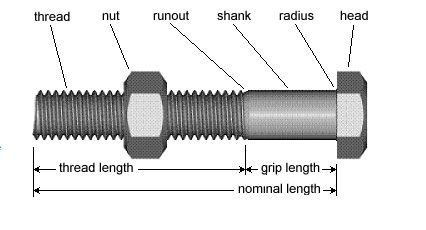

Some of the main parts and components of bolts and nuts include the following:

Parts of bolts and nuts

· Head

The head of the hex bolt has six sides thus the name hex bolt.

It has different dimensions among them the diameter which is often more extensive than the rest of the nut.

It is the most substantial part of the hex bolt without the nut.

· Grip length

The grip length is the distance between the head of the hex bolt and the threaded area of the hex bolt.

The range has a measure in millimeters and does not have threads.

In most cases, the grip length is often longer than the threaded length.

· Thread length

The thread length is the distance immediately after the grip length.

It has a series of threads of different lengths depending on the type of bolt.

It is the part of the bolt where the nut attaches.

· Nominal length

In the manufacturing industry, nominal length is also the trade size or nominal size of the hex bolt.

It may not match or comply with any dimensions on the bolt, but the main scope falls within the nominal size.

In simple terms, it is the length you will arrive at by adding the grip length and the thread length of the hex bolt.

· Thread

It is a helical structure that converts between linear and rotational force or movement on a hex bolt.

It is the ridge that wraps around the hex bolt as a helix.

It is the point where the bolt and the nut join and stick together

· Nut

It is a hollow piece of metal with threads on the inside usually working in conjunction with a bolt.

It is a type of fastener used to hold and tighten two different parts together.

· Run out

It is the point on the hex bolt where the thread of the hex bolt begins.

It is the point where the grip length and the thread length meet.

It is the point where the grip length ends, and the thread length begins.

· Radius

It is the point where the head of the hex bolt connects to the grip length of the bolt.

It is a junction that connects the head of the hex bolt to the entire body of the hex bolt.

Technical Specification of Hex Bolts and Nuts

Before you buy any hex bolt and nut, it is important to consider the following:

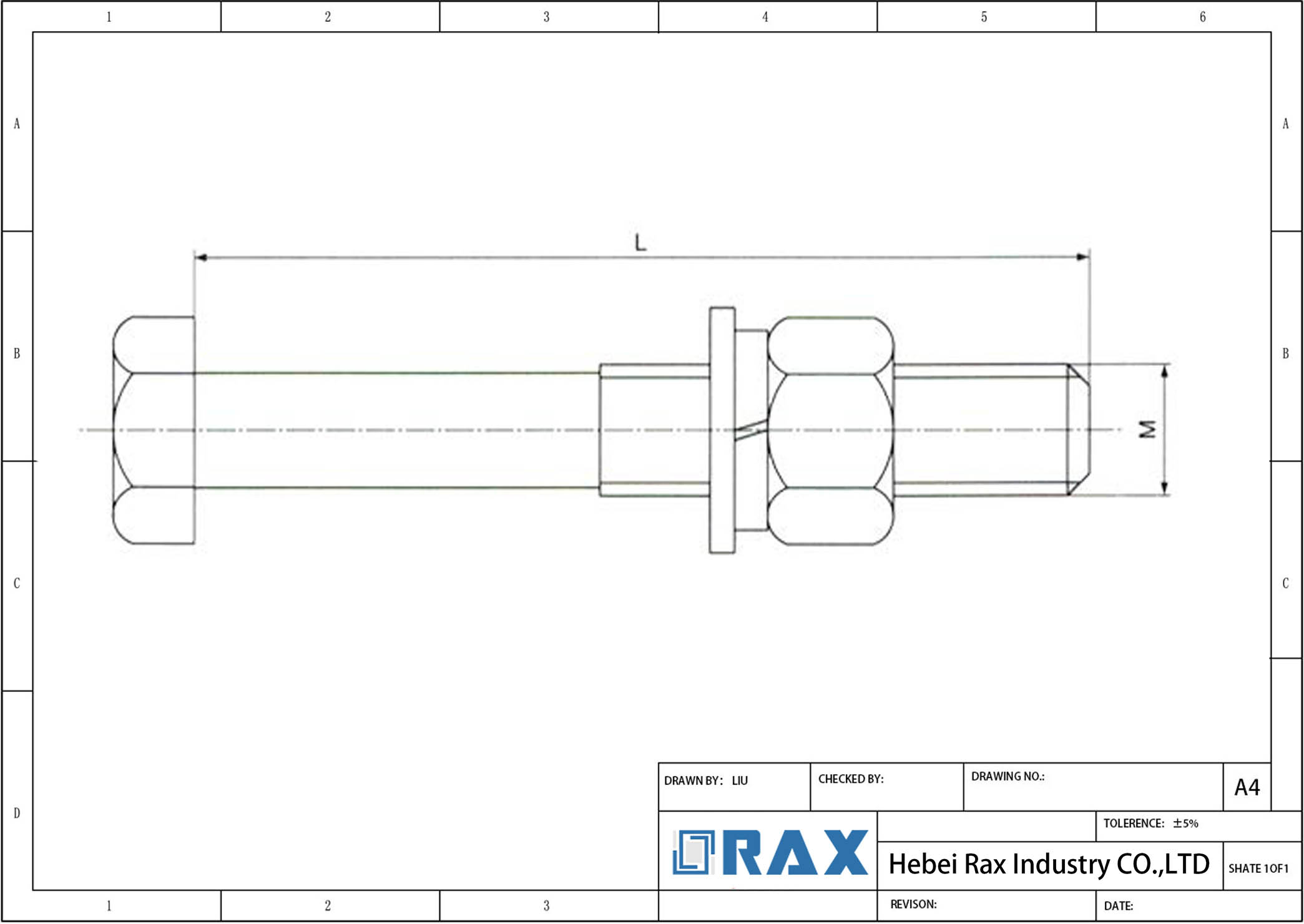

Technical specification of hex bolt and nut

Hex bolt and nut diameter

The most popular dimension to consider on a hex bolt and nut is the diameter and the length.

The most common types of hex bolts and nuts are a ½ inch, 5/8 inch and ¾ inch.

The threads of the bolts mentioned above range between 100 mm to 400 mm.

· Thread range

When you are looking at a hex bolt and nut, do not forget to look at the tread range.

The most common thread range is between 100 mm to 400 mm.

The unit for measuring the thread range is millimeters.

· Material Type

The most common material used in making hex bolts and nuts is steel rods.

There may be other types of materials but steel is the most common.

Steel corrodes easily and it has to pass through the process of hot dip galvanization to make it corrosion resistant.

· Finish – hot dip galvanization

Since steel corrodes, you will have to pass it through hot molten zinc to provide it with an extra coat.

The thickness of the extra coat is 43 microns according to ISO 1461 standards of hot dip galvanization.

The extra coating makes the hex bolt and nut resistant to corrosion.

· Tensile strength

The tensile strength of the hex bolt and nut will vary according to the material and thickness of the device.

Steel is very strong thus providing the hex bolt and nut with very high tensile strength.

The thicker the material used the higher the tensile strength of the bolt and nut.

· Standard Specifications

Standard specifications on hex bolts and nuts vary from one country to another.

In the United States, the American Society of Mechanical Engineers and the American National Standards Institute control the standards.

In Britain, the institute for controlling standards is the British Standards Institute and DIN in Germany.

Institutes that inspect and set standards for manufacturing vary in different countries even though they advocate for the same thing.

Apart from that, all these standards have to meet the International Standards Organization (ISO) standards before selling them.

The Society of Automotive Engineers (SAE) are also part and parcel of the inspection, and they have their rules.

Hex Bolts and Nuts Manufacturing Process

The process of manufacturing hex bolts and nuts is quite simple as it requires simple machines.

No matter how simple it may seem, you should not forget to put on protective gear.

The primary raw materials you will need in this case are steel, measuring tools, and cutting tools.

First, you will measure the length of the bolt you will need and using a cutting tool make the right cut.

The same is done for the nut making sure that the sizes are as specified by the customer.

The long steel rod which will turn into a bolt passes through the process of hot forging.

The steel rod passes through an electric stove to heat it until it is red hot.

Be careful not to cause any burns on your body as it may be tragic.

The hot rod is taken through the process of punching thus gaining the hexagonal shape.

The nut is also taken through the same process but after making a hexagonal shape on it.

You will have to drill a hole of the same diameter as the diameter of the bolt.

This will ensure that the bolt and the nut fit perfectly.

After that, the steel rod with a hexagonal head passes through a rolling machine.

The rolling device will make the threads on the other end of the steel rod making it a complete bolt.

You will also pass the nut through a drilling machine which will make the threads inside the nut.

The last process is hot-dip galvanization where the steel rod passes through molten zinc.

It will react with the molten zinc to produce an outer coat that is resistant to corrosion.

After that, cool them down and then try fitting them together to confirm they are perfect.

Step-by-step Hex Bolts and Nuts Installation Process

Joining one pole line hardware to another may require the use of a hex bolt and nut.

You will have to choose the right size of the bolt and the nut depending on the parts you need to fasten together.

The process of installation is rather simple, and you will be able to manage it without an expert.

Different sizes of bolts and nuts

Collect all the requirements and place them close to the working site.

You will need help from other people to help you hold the different parts that you intend to fasten together.

Join the different pieces together making sure that the holes match.

Holding the parts together, remove the hex nut from the hex bolt allowing you to insert the hex bolt into the holes.

It should fit perfectly into the hole if you have the right size of the hex bolt.

After that, adjust the nuts and use a wrench to fasten it to the end.

It is a simple procedure but does not forget to follow the safety rules and procedures during the installation process.

Frequently Asked Questions (FAQs)

What is the function of a hex bolt and nut?

A hex bolt and nut is used to fasten and join two different parts of pole line hardware or power line accessories together.

What is the raw material of hex bolt and nut in your factory?

Only carbon steel hot dip galvanized hex bolt and nuts used on pole line or transmission line are manufactured in the factory.

What is the quality standard of hex bolt and nut thread?

The hex bolt and nut thread are made according to UNC or BS,it also can be made as to the customer's demand.

How to choosing the manufacturer of hex bolt and nut?

Here are some guidelines you can follow to choose a suitable manufacturer:

- Check whether the company is licensed

- The production capacity of the company

- Look for the reviews about the manufacturer

- Experience of the manufacturer

Conclusion

I am sure that you are in a better position to make the right choice on the kind of hex bolt and nut you need.

Remember that manufacturers welcome ideas on how they can improve and design a hex bolt and nut for you.

Look at your connections again and make the right order for your hex bolt and nut as soon as you can.

At Rax Industry, we are here to ensure you get the right hex bolt and nut.