Manta Ray Anchor

The Manta Ray Utility Anchor is a trailblazing development in anchoring technology. Used widely by the construction, telecoms, and utilities industries across the globe, they provide an uniquely easy and efficient remedy to a variety of structural reinforcement and repair requirements.

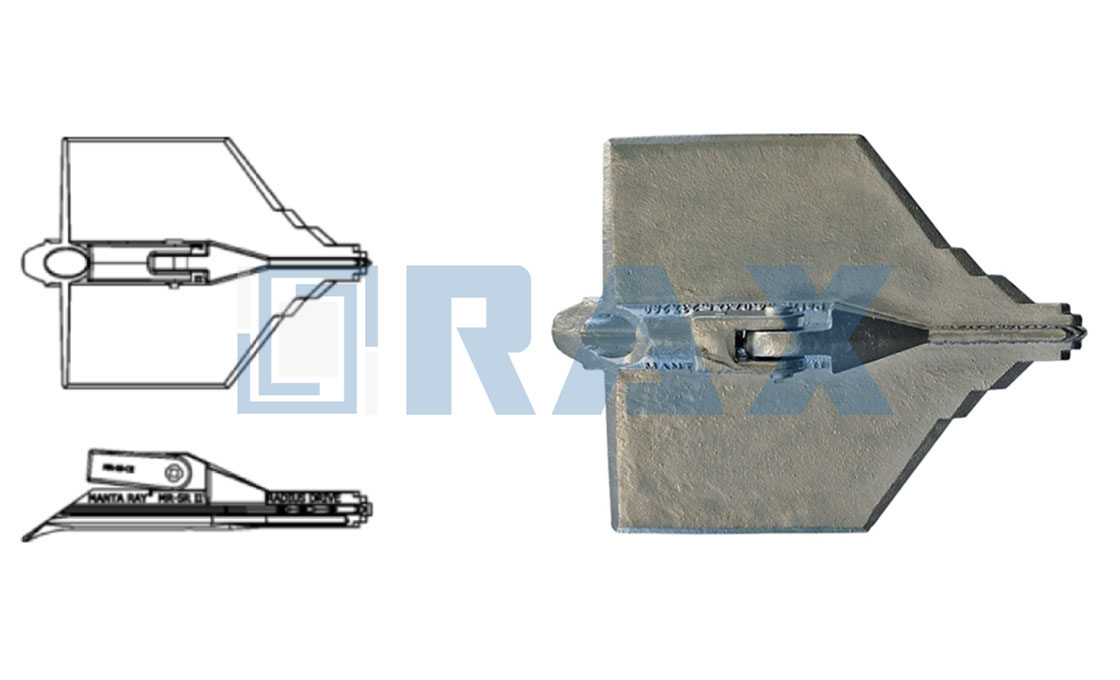

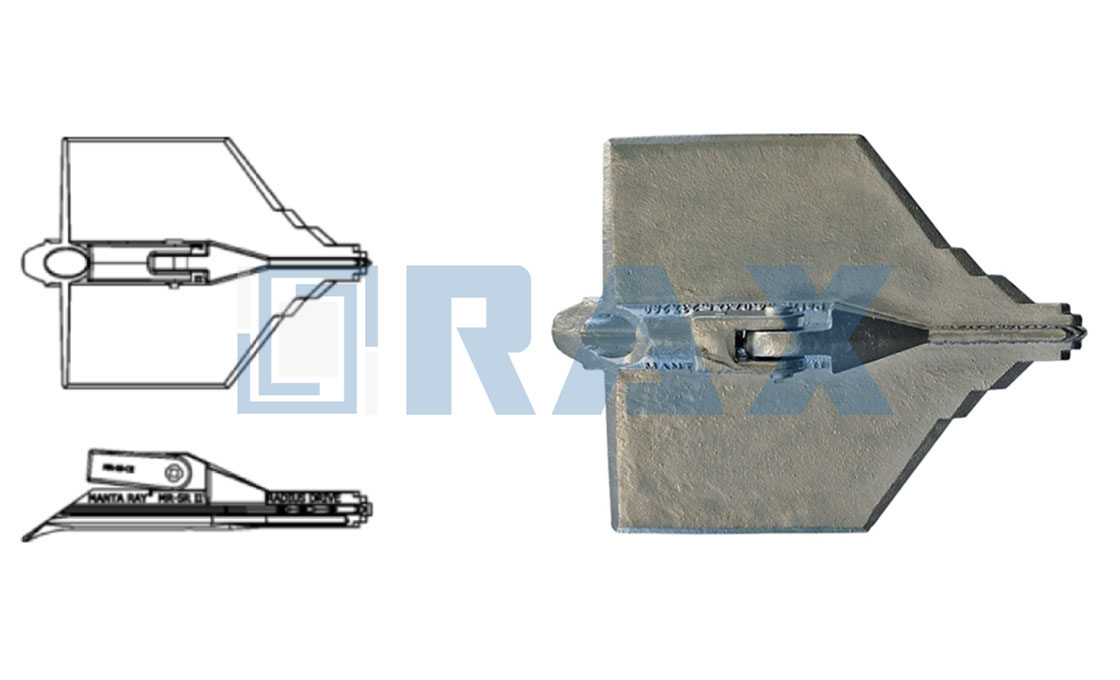

Designed to be driven directly into the earth, Manta Ray anchors completely dispense with the hassle and expense of drilling and digging holes. Extremely versatile, they can also be installed into a wide range of soil types including glacial till, caliche, and even eroding rock.

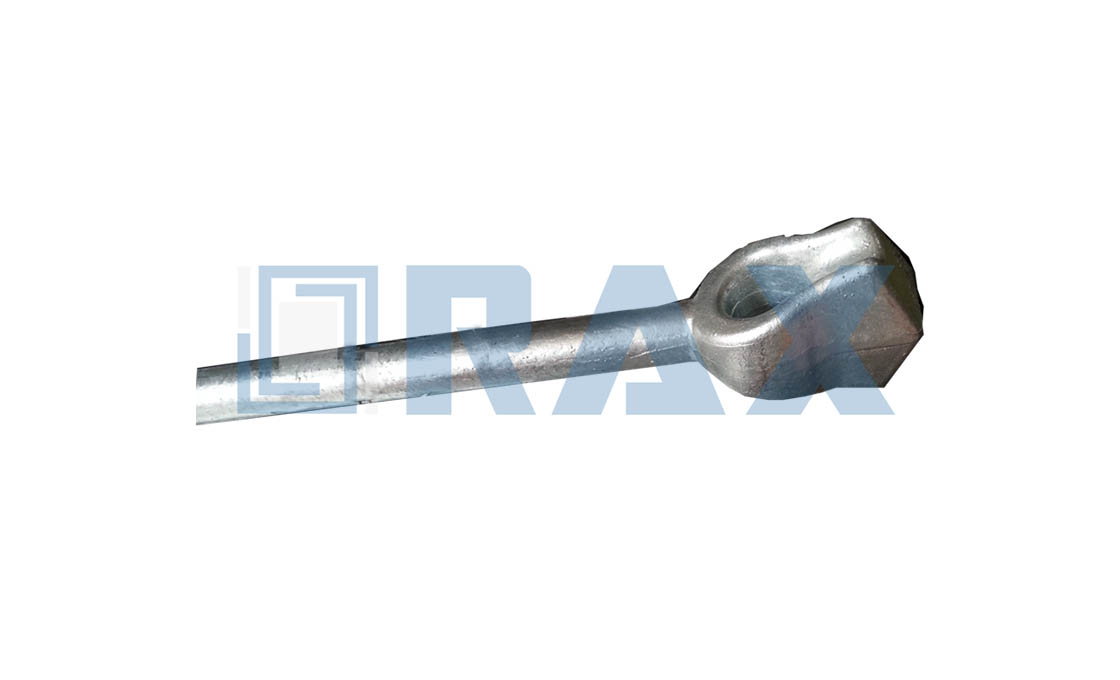

Manta Ray Anchors come with fully threaded rods, ready to be field cut and coupled. They are also compatible with standard anchor eye nuts.

A speedy, safe, and simple solution to a range of anchoring needs!

Product Features

- Fully threaded bar

- Variable bar length

- Versatile application

- Easy, fast installation

- No digging/grouting

- Load measure gauge

- Instant proofing result

- Simple locking system

- Dipped galvanised iron

- Excellent load capacity

- Environmentally Friendly

- Meets Spec ASTM A153

Anchor rod length ranges up to 50 feet.

Notes

It is recommended that rods are cut to size prior to galvanizing to ensure a good nut fit.

Installation requires the assistance of machinery. Manual installation is not recommended.

| Model | For PH Rod Size | Ultimate Load Rating (lbs) | Weight (lbs) |

| MR-1 | D75 (3/4”) or D100 (1”) | 23,000 or 36,000 | 13 |

| MR-2 | D75 (3/4”) or D100 (1”) | 23,000 or 36,000 | 11 |

| MR-3 | D62 (5/8”) | 16000 | 7 |

| MR-SR | D75 (3/4”) or D100 (1”) | 23,000 or 36,000 | 21 |

Manta Ray Anchors: A Guide

Manta Ray anchors are long, spear-shaped engineering tools frequently used in the utilities, telecommunication, and construction sectors to strengthen or stabilise upright structures.

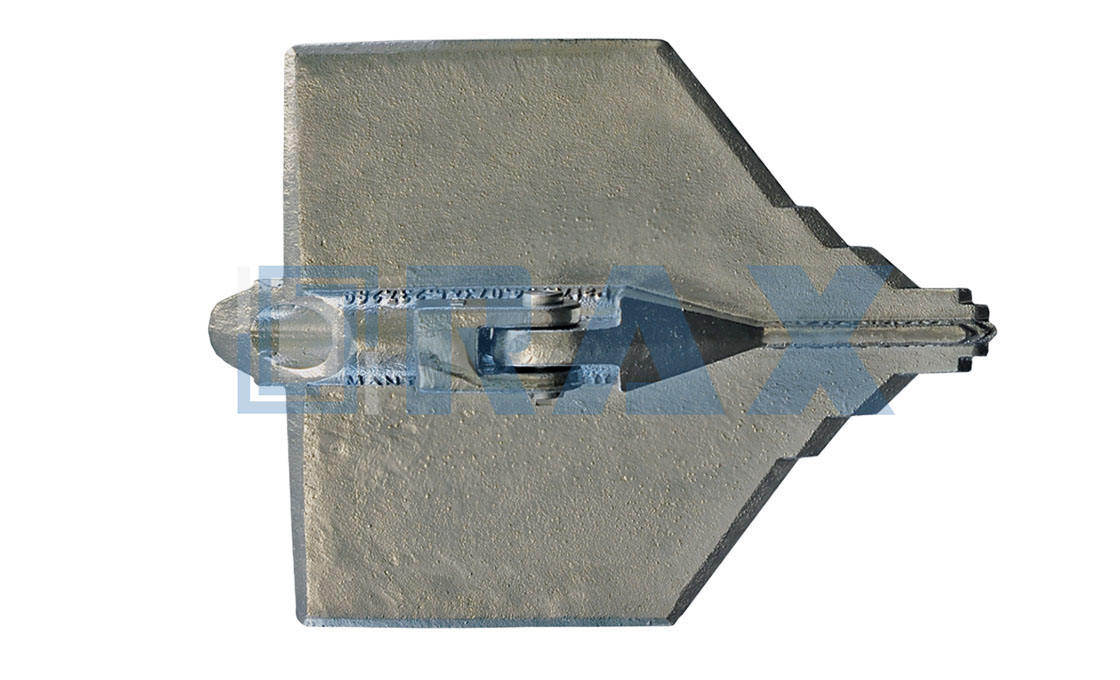

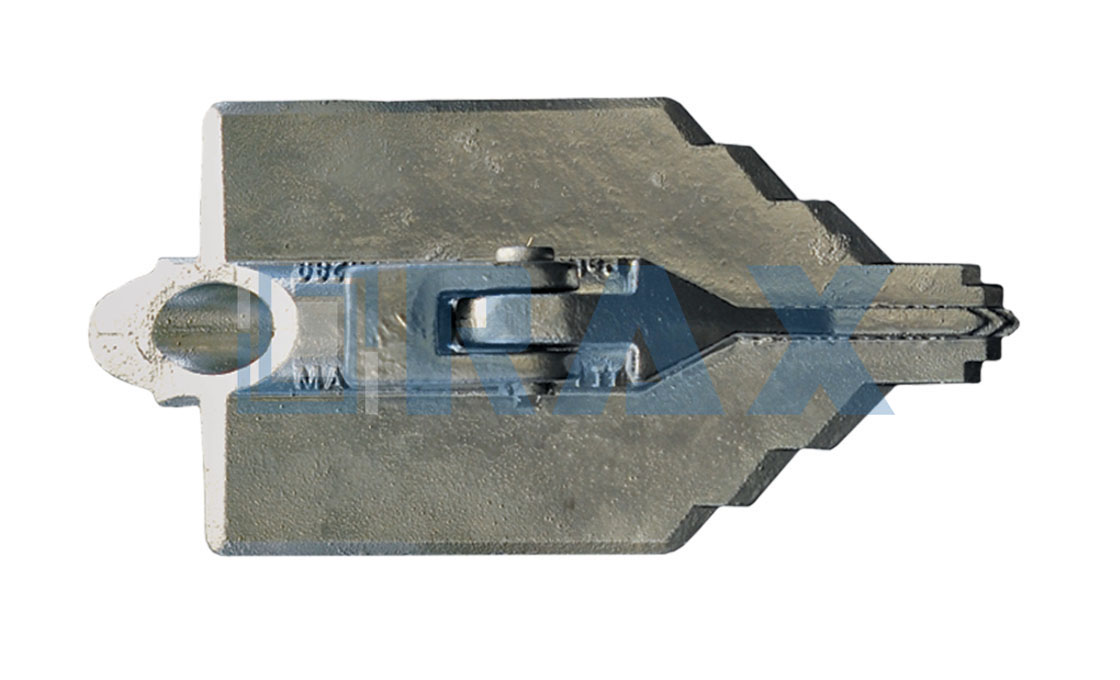

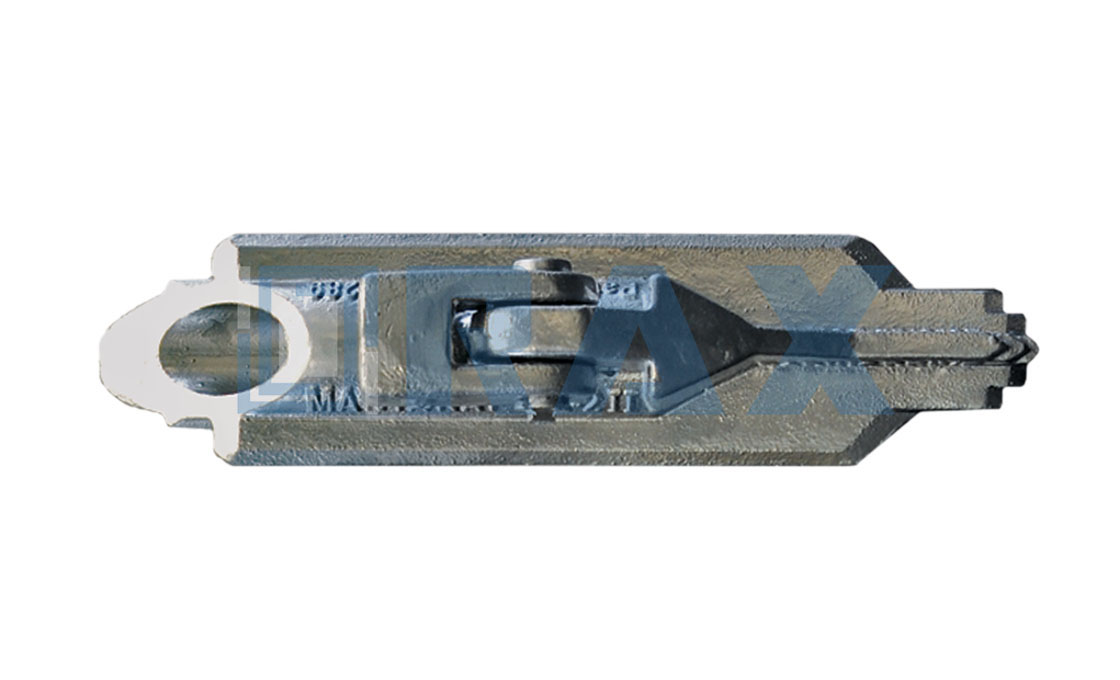

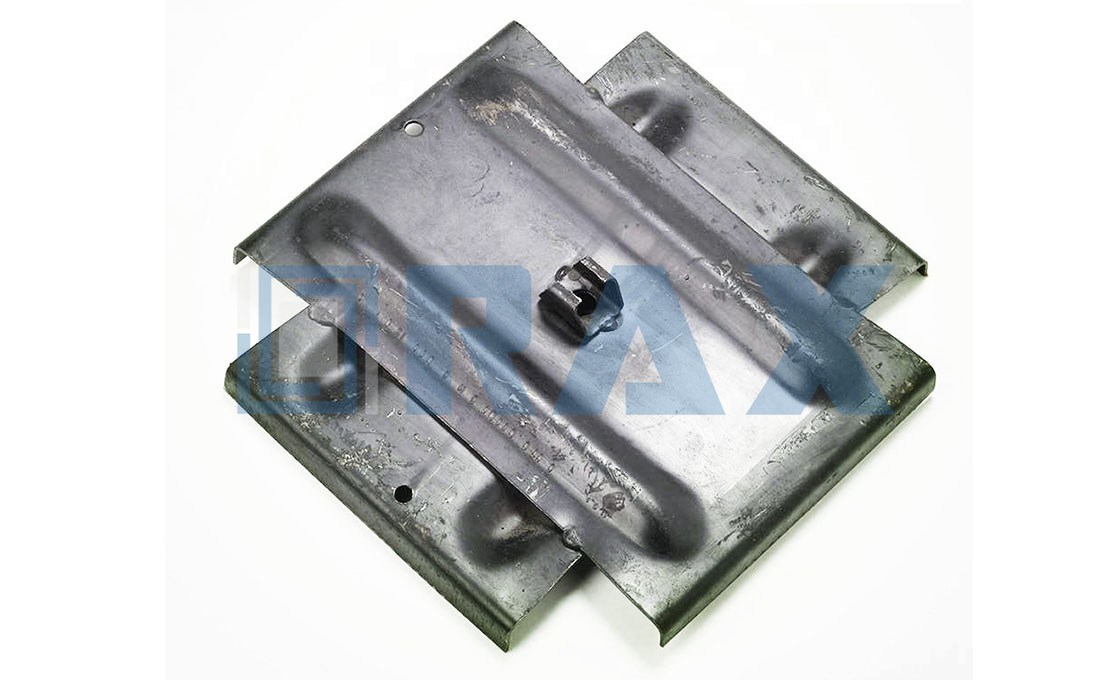

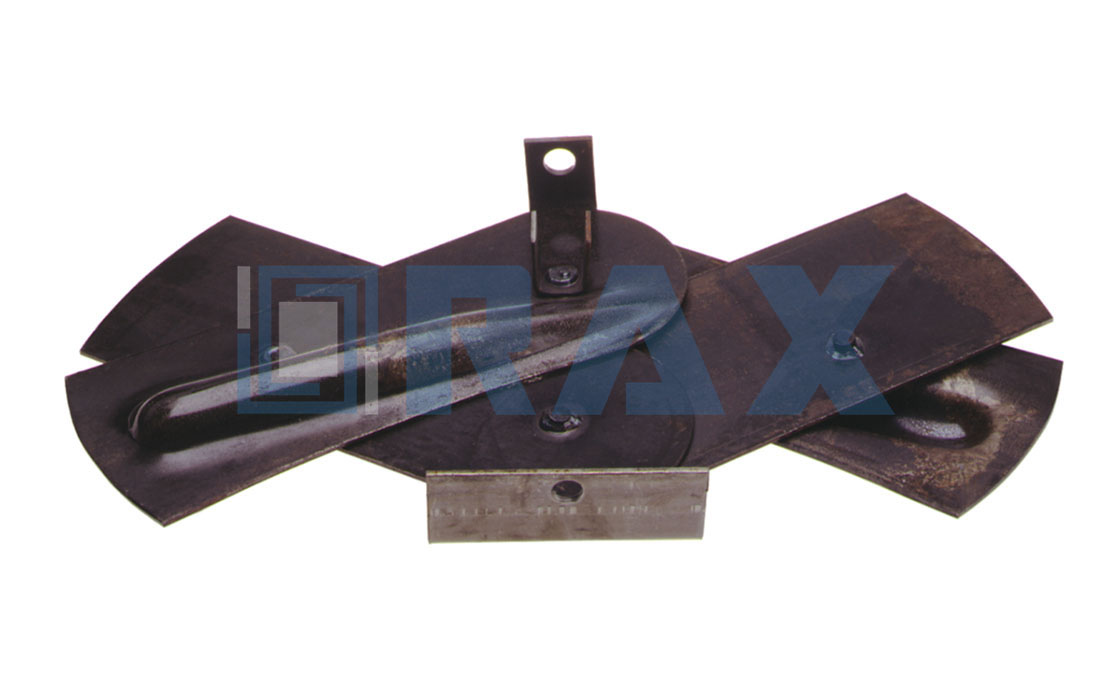

The Manta Ray Anchor is a type of driven plate soil anchor used to repair or provide reactionary reinforcement to a range of man-made structures such as utility poles, walls, pipelines, scaffolding, and many other heavy duty constructions. The versatile and cost-effective design of the Manta Ray Anchor is considered to be a pioneering innovation in the earth anchoring industry, and is widely utilised by a variety of sectors working with outdoor constructions. Unlike other forms of anchoring technology, the use of the Manta Ray anchor does not cause a displacement of soil. Instead, when used it is designed so that soil compacts around it – eliminating the time, labour, and cost involved in removing and rehoming excess earth. Its serrated ray-shaped tip pierces the surface soil, from which point the anchor can be machine-driven into the earth to the necessary depth. Once in place, the anchor bar is drawn upwards, rotating the inserted end of the anchor into a 90-degree angle and locking it in place. Once secure, a gauge on the anchor can be used to measure the holding capacity. The anchor can then be proof loaded as needed. Manta Ray anchors are crafted from galvanised ductile iron. The upper operative end is similar to the handle of a screwdriver, whilst the lower, inserting end resembles a stout, pointed garden spade, with deeply serrated edges for driving deep into the soil. There are eight models of Manta Ray anchor, designed to resist varying tensile loads of up to 20 tons. They come in two length ranges - models B8S-03 and B8S-04 are suitable for lengths up to 20 feet, and models R61-06 to R61-09 are suitable for lengths up to 50 feet. All Manta Ray anchors have a load locker, which enables the Manta Ray anchor to be tested to the desired holding capacity during installation procedures. Manta Ray Anchors are required to meet the industry standard ASTM A153-2005 to deem them fit for use. Manta Ray anchors are designed ready-made to be driven into the ground, removing the need for digging, drilling, or grouting. Their installation must be completed with the assistance of pneumatic or hydraulic machinery to ensure maximum safety and efficiency. The main machinery installation options are: a) vehicle-mounted pavement breakers; b) breakers or compactors (such as excavators, skid steer loaders, or backhoes) or c) rock drills (e.g. top hammers). Once the chosen machinery is available, the basic steps of installing a Manta Ray anchor are:

What is a Manta Ray Anchor?

How do Manta Ray Anchors work?

Manta Ray Anchor Features

How to install Manta Ray Anchors?

Final Thoughts

As headway within the hub of infrastructure continues at a rapid pace, new means and methods of adapting to an increasingly modern landscape are emerging. Tools and techniques which break new ground – in more than one sense of the word – promise possibilities of progress in increasingly efficient and economically friendly ways. Manta Ray anchors are a perfect example of how these intelligent, innovative ideas can not only transform our terrain, but accelerate our advancement towards new horizons.