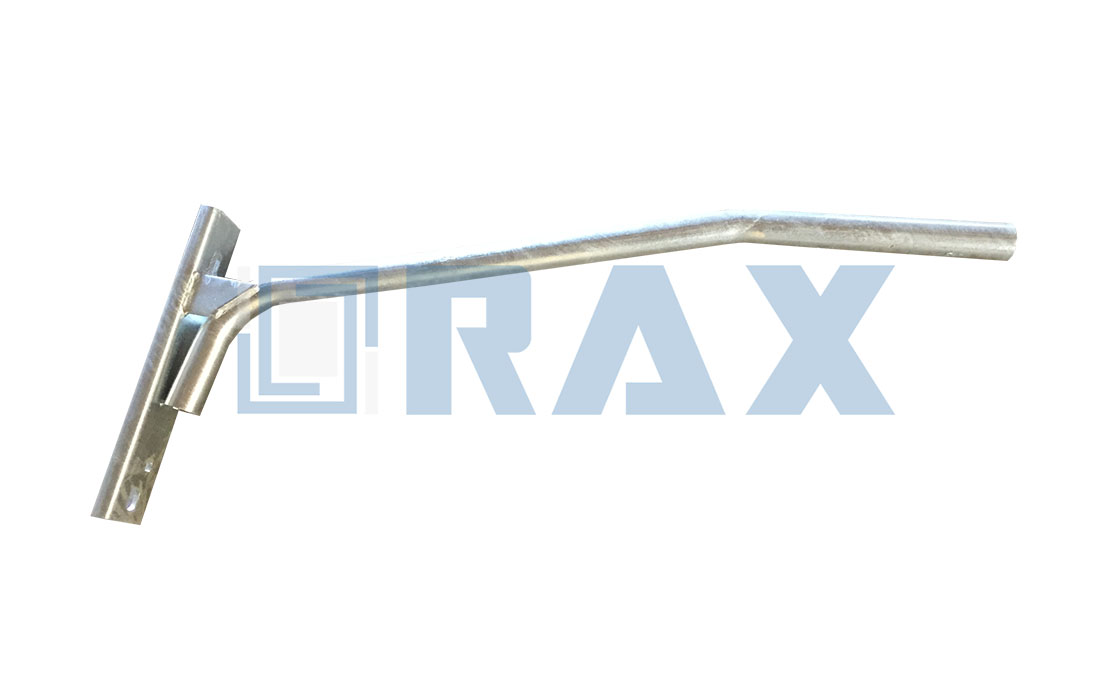

Street Light Arm

The street light arms are mainly used on outdoor lighting poles, they can connect and support types of street lights, such as metal halide street lights, high-pressure sodium (HPS) street lights, low-pressure sodium (LPS) street lights, and light-emitting diode (LED) street lights.

The street light arm is also called light pole brackets, street light mounting arm, street light mounting bracket, street light pole arm, or light mounting arm.

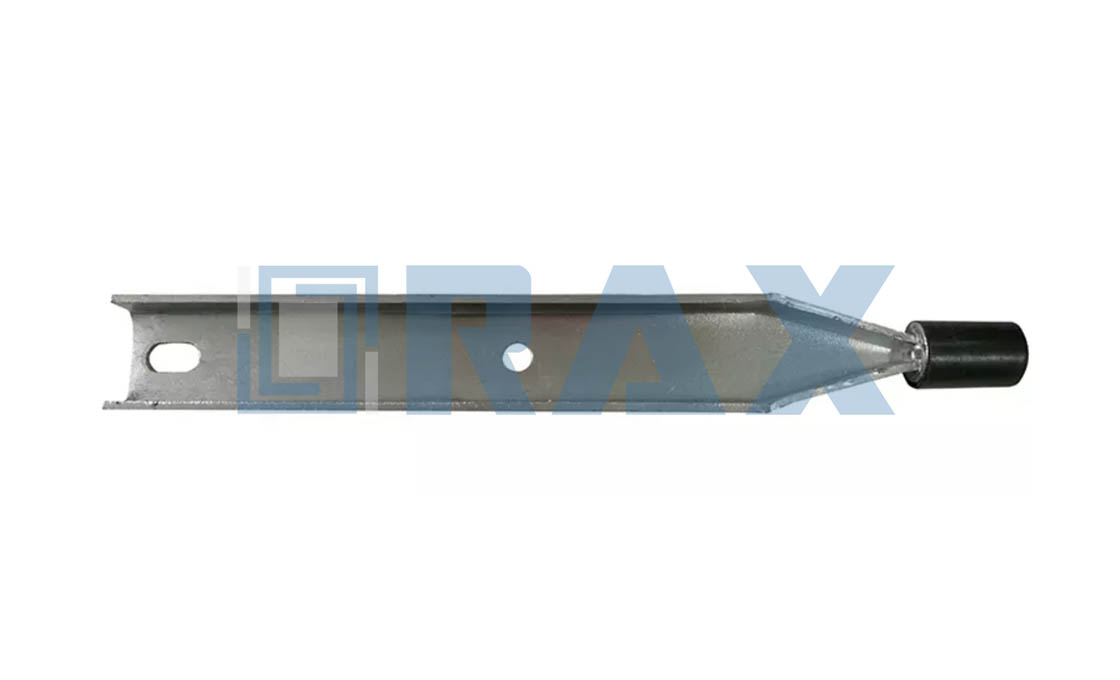

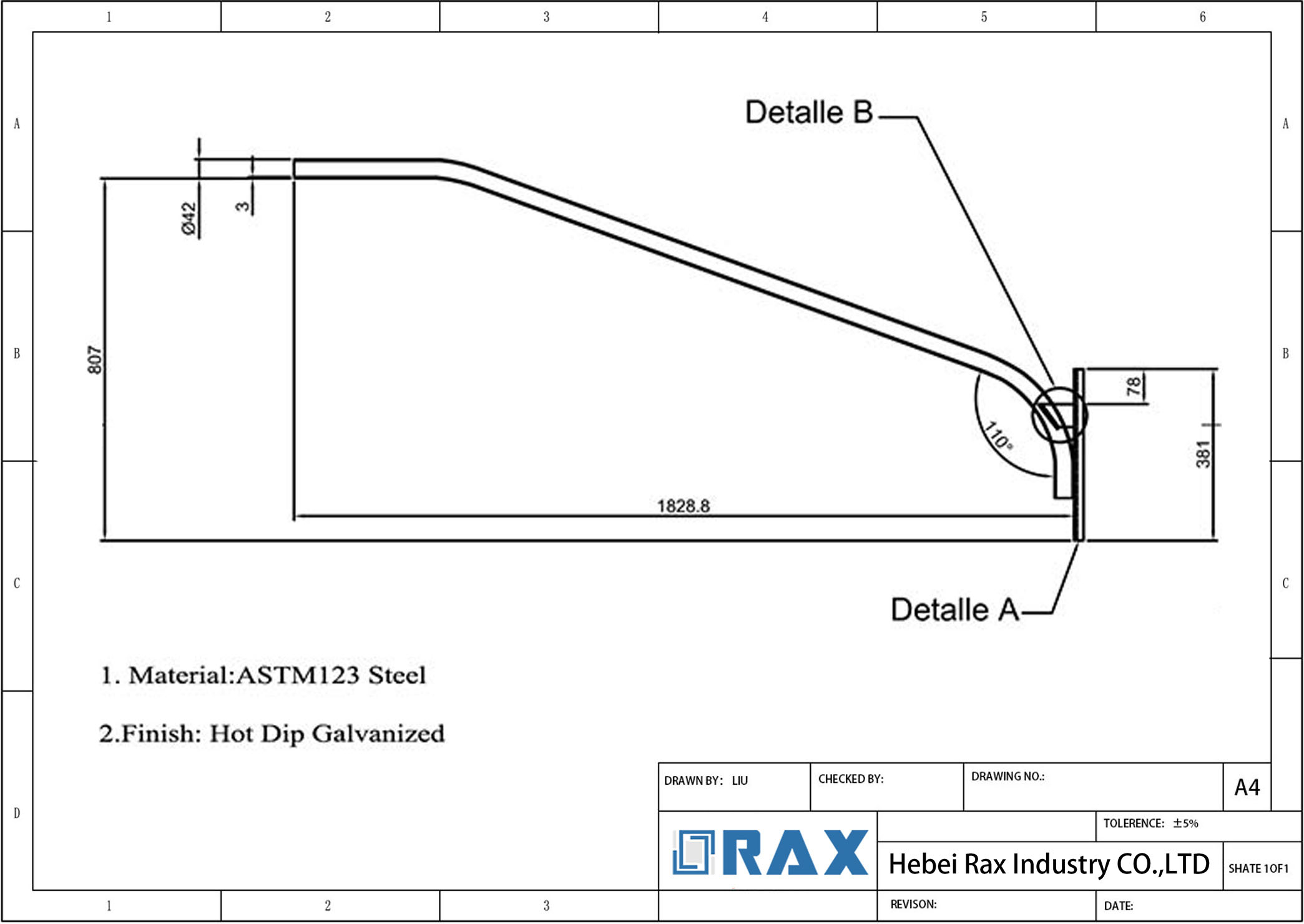

There is a length of 300mm parallel tube at the end. This part is used to assemble the led street light.

The other end of the street light bracket arm is a bracket base. This light pole arm bracket base is fixed on the pole.

The main raw material of the light pole bracket is steel tube and flat steel.

All materials are new and not recycled. The thickness of the tube is 3mm, the steel tube will be welded on the flat steel base.

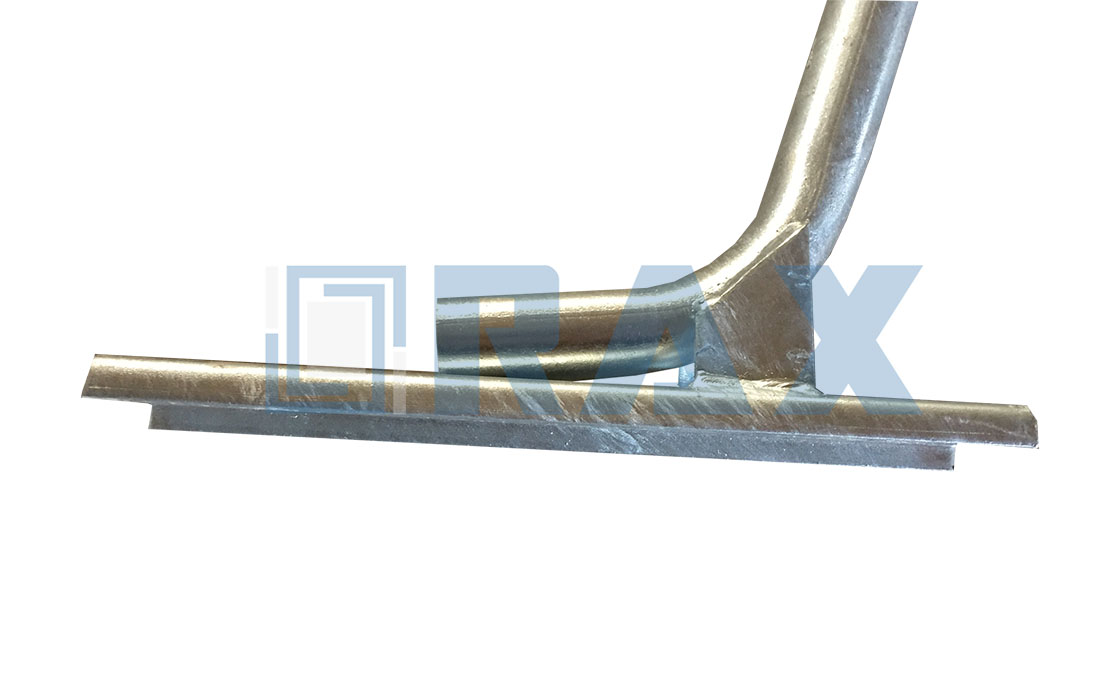

To make the tube welded on the flat steel steady, there are two small flat steels welded between the steel tube and flat steel. Rax Industry street light arms are metal-arc welded. And Rax Industry street light bracket arms welding meets the BS5135 standard.

After street light arm welding and before galvanizing, Rax Industry street light pole arm welds will be thoroughly cleaned to remove slag and spatter. Rax Industry workers do the cleaning on the street light mounting brackets by sandblasting.

The final street light arm is hot-dip galvanized. Rax Industry does the hot-dip galvanizing according to the standard ASTM123-78.

Rax Industry team will do the second time selection after the hot-dip galvanization. This way, Rax Industry successfully passes the SGS inspection on each delivery.

As an ISO-certified manufacturer, supplier, and exporter, Rax Industry pays attention to quality and customer requirements.

Steet light arm details:

Rax Industry street light arms which are exported to South America are manufactured of steel tube cedule40, grade B. Rax Industry street light arm South American type outer diameter is 42.2mm, the thickness is 3.56mm. The drawings are attached in the other tab.

Rax Industry street light arms are made holes and marked figure before hot-dip galvanizing.

| Street light arm | Maximum approx. length

| Maximum approx height:

| Minimum zinc coating

| I.D mínimum

| Tube thickness

| Weight(kg)

|

| Date | 2m

| 1.01m

| 49um (micras)

| 38,1mm (1,5”)

| Between 3,7mm and 4,0mm, cedule 40,

| 11 |

| Standard | per ASTM A123/A123M-02

| per ASTM A-312 and ASTM-530

| grade B. |

Rax Industry street light armTorsion strength:

Rax Industry street light arm with its pole bands can withstand a torque effort, without failure when applied the force of a body of 75kg, hanging from the far end of the arm,1.5m from the outer side of the vertical section which has the holes, that is, at the point where the luminaire will be installed.

Rax Industry street light armFinishing and presentation:

To avoid damaging the cables to be ducted, all edges and burrs will be removed by polishing. The polishing in the holes and edges will be clean and smooth.

| Product Specifications | ||

| Product Name | Street light arm 6’ | Street light arm 8’ |

| Code | JY-STA-6 | JY-STA-8 |

| Tube thickness | 3mm | 3mm |

| Product Finish | Hot Dip Galvanized | Hot Dip Galvanized |

| Material | Carbon Steel | Carbon Steel |

| Length | 6’ | 8’ |

| Standard Package | Pallet | Pallet |

| OEM | YES | YES |

| Standard | ASTMA-123 | ASTMA-123 |

| Production time | 3-4 weeks/4000pcs | 3-4 weeks/4000pcs |

| Payment item | T/T 30% DOWNPAYMENT | T/T 30% DOWNPAYMENT |

Q1: How much does a Street Light Arm cost?

A: Our factory price will save you 20% cost, once we confirmed the specification, we can send you the competitive price.

Q2: Which market does your Street Light Arm export to?

A: We mainly export the street light arm to South America and Southeast Asia.

Q3: How does the Street Light Arm pack?

A: We pack the street light arm in a unique way. The packing is stable and uniform.

Q4: What’s the MOQ for Street Light Arm?

A: Generally the MOQ for Street Light Arm is 500pcs.

Q5: Can I have a sample order for Street Light Arm?

A: Yes, we can provide the Street Light Arm sample for free, the delivery cost is usually paid by the customer.

Q6: What’s the payment terms for Street Light Arm?

A: The payment for Street Light Arm is usually T/T 30% as advance payment and 70% T/T before sending the Street Light Arm.

Q7: Will you charge for the tooling if you do the OEM?

A: We are good at developing a new design for the customer, the tooling is usually paid by the customer, but if the order quantity is more than 5000pcs, we will refund the tooling cost when confirming the order.

Q8: Can you send us a price list for all types of Street Light Arm?

A: We have many customized types for Street Light Arm, so the price is always changing based on the raw material and different customer requirements. It’s better to give us a general description of your requirement, we will supply the best schedule for you.

Q9: What’s your delivery time for Street Light Arm?

A: The delivery time for10000pcs Street Light Arm is usually 6 weeks. Pls, contact us, if you need an urgent order. We will supply a solution for you.

Rax Industry street light arm Packaging:

Rax Industry street light arm is stowed and accommodated by wooden pallets which are suitable for carrying by hydraulic truck or forklift.

To fasten the street light arm to be delivered, Rax Industry workers use plastic or metal tape(known as the strap) to attach the street light arm to the platform firmly.

The label which is written with the street light arm numbers measures and description will be put on each pallet to identify the goods easily.

Street Light Arm: The Complete Guide

Thinking of installing street arms?

There’s something critical you need to know.

In today’s guide, I am going to walk you through important aspects to consider when buying street light arms.

I will focus on the main features, parts, features, and designs of street light arms.

By the end of this guide, you should be able to choose appropriate street light arms for your unique applications.

Let’s dive right in:

What is a Street Light Arm?

A street light arm is an extension on street light poles that helps enhance illumination on outdoor lighting poles.

I am talking about this:

Apart from the common term street light arm, you can also refer to this accessory as:

- Light pole arm bracket

- Light pole bracket

- Streetlight mounting bracket

- Streetlight bracket arm

- Lighting mounting arm

- Streetlight mounting arm, etc.

The market offers an innumerable array of street light arm items that may be a daunting task to show worth and reliable products.

Rax Industry Street Light Arm

Rax Industry Street Light Arm

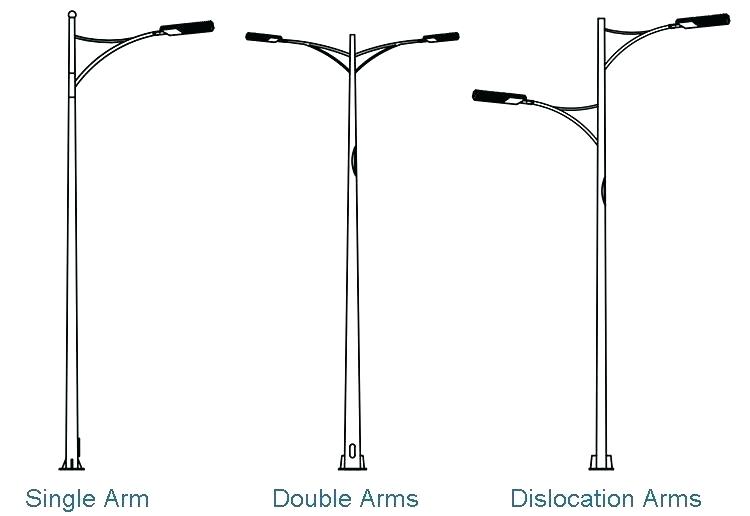

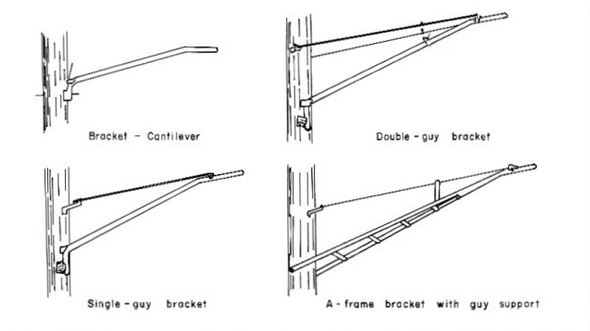

For a fact, street light arms come in different shapes and designs.

Also, they feature different materials.

I will come to that later in this guide.

But remember, the choice of material is quite critical here.

For example, some street light arms feature a high tensile strength material.

Apart from the material, the design is also critical here.

It determines whether the arm can support the weight of the lamp.

Besides, determining whether it can withstand high-speed wind or any other adverse weather conditions.

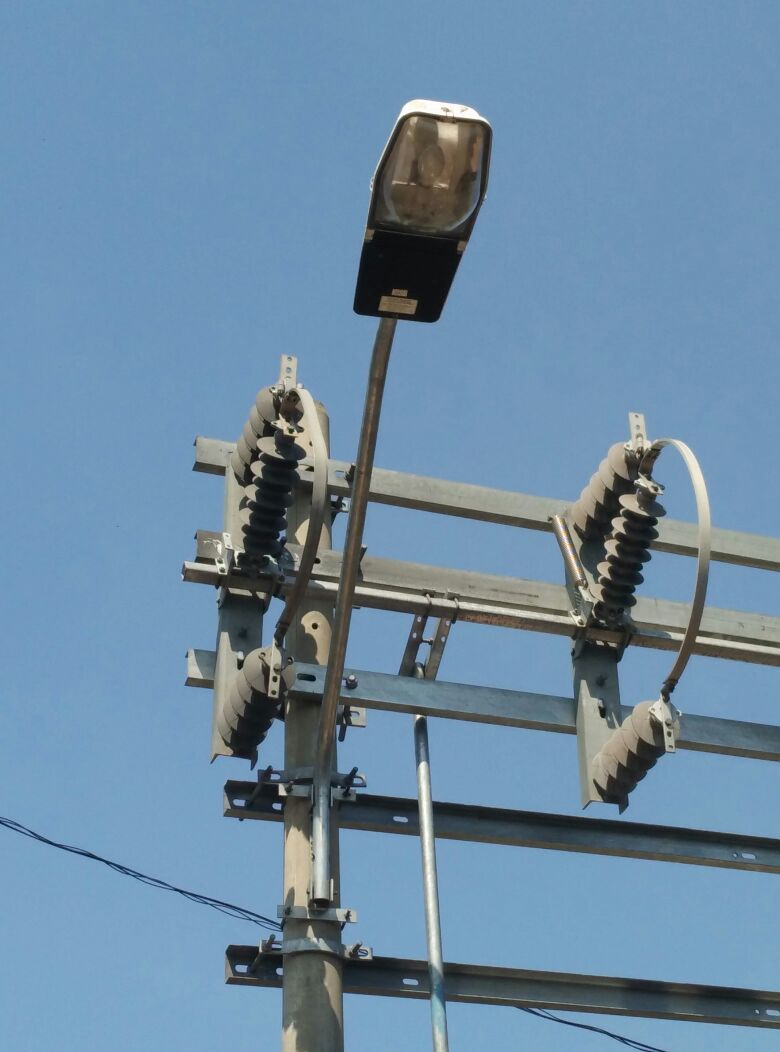

As the name suggests, street light arms are for outdoor lighting posts.

In essence, the street light arms offer support and connect the lighting devices like LED street light, on the main street light post.

LED lamps on street light arms

As you can see, it ensures the LED street light illuminates properly on the street as well as the pedestrian paths.

Hence, there is no need to erect extra street light posts on the pavements.

How to Make Street Light Arms?

Although the process of making street light arms may seem simple, choosing appropriate manufacturing technology and material are still critical.

Why?

It is because they determine the lifespan of the street light arm.

Moreover, from this alone, you can tell whether it can hold a lamp or not.

Side view of the street light arm

Side view of the street light arm

Anyway, let me walk you through this process:

1. Designing Stage

Here, you must choose the design and shape of the street light arm.

This will depend on both the functionality and beauty you’d wish to add to the environment.

Normally, street light arm manufacturers will help you design an appropriate accessory.

Of course, the design should focus on the length and material forming the street light arm.

Moreover, it should put into consideration the bracket base.

In most cases, the main material for street light arms is flat steel and steel tube.

2. Fabricating Street Light Arm

Mostly, the process involves welding steel tube to a flat steel base.

To make the arm stable, you may add some reinforcements between the flat steel base and the tube.

The welding process should conform to BS5135 standards.

What follows here should be a thoroughly cleaned surface – more specifically the welded joints.

By doing so, you’ll have a smooth and fine finish without either spatter or slag.

Sand blasting is a perfect procedure for this kind of task.

Round street light arm

3. Finishing Operations

In addition to this, it is important to take the street light arms through the galvanization process.

Of course, this is after welding and cleaning the welded street light arm.

Galvanization is a process of applying a metal coating on other metals to protect them from corrosion such as rusting.

Remember, you will be using these street light arms for your outdoors.

Therefore, it is important to galvanize them during the production process to improve their service life and durability.

So, what happens here?

The welded street light arms are dipped in hot zinc to form a protective coating on the surface.

This process is done according to ASTM123-78 standards.

Also, the galvanized street light arms must pass strict quality control and inspection.

Different designs of street light arm

This is the reason why Rax Industry street light arm products have a commanding stake in the market.

The thoroughness of the production process helps to pay attention to details to meet customers’ requirements.

Main Parts and Components and Features of Street Light Arm

In this section, you are going to learn more about features to focus on the street light arm.

These features will enable you to choose a correct street light arm that suitably serves your application environment.

Different designs of street light arm

The following are some of the essential features that you should consider for an ideal street light arm:

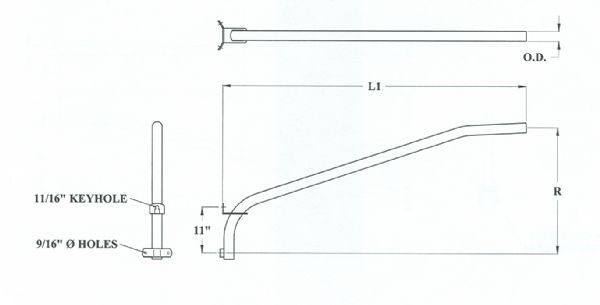

1. Street Light Arm Base

It is the street light arm base that will support the lamp.

The street light arm base should have slots to accommodate some inches of bolts to hold them firmly against the street poles.

2. The material of the Street Light Arm

The design service life of a street light arm should guarantee a long service lifespan.

Here, you need to consider the quality of the material.

It will determine whether the street light arm will serve you for a long time or not.

3. Street Light Arm Size

Most polearm designs may differ, but manufacturers use standard measurements in making various street light arms.

It depends on the specific requirements of customers.

However, the AS 1798 data are mostly preferred standard measurements in the design of street lighting brackets.

Thus, remember to use the data as your reference when in search of new street light arms.

The 6.5m, 10.5m, and 12.5m are standard heights for street poles, and 3 m are the street light arm projections.

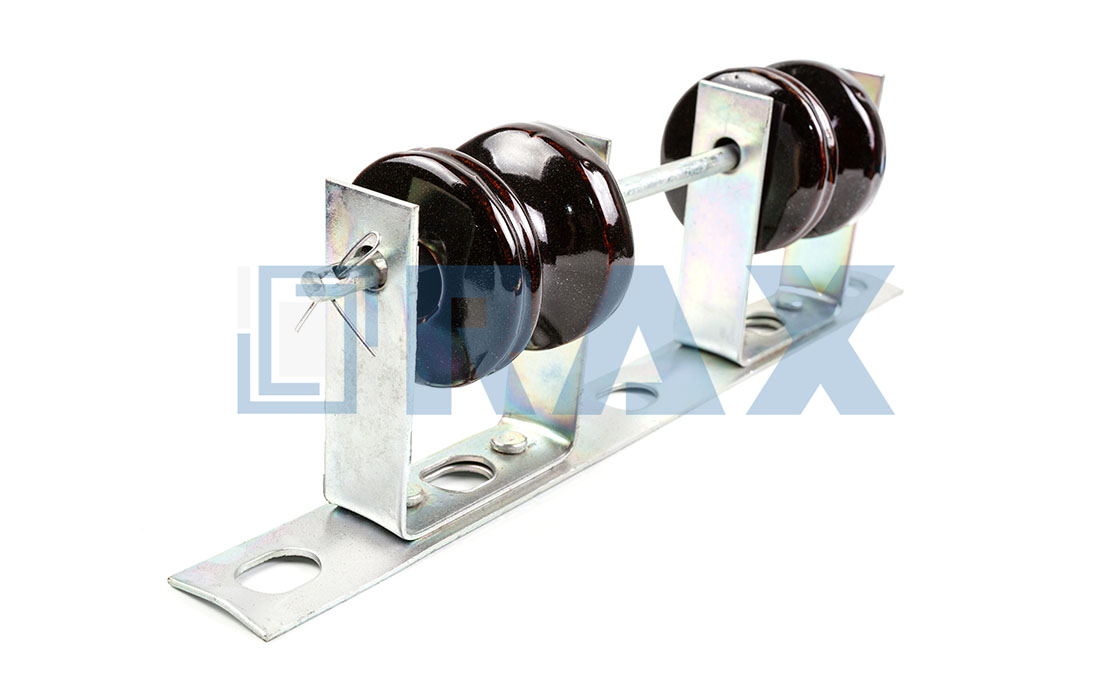

4. Fixtures and Fittings

Streetlight arms, for all applications, should have fixtures and fitting devices on the street poles.

The street light arm must have a sturdy structural strength.

With this, it will remain in position all the time after installation.

Remember, you should mount a street light arm on a 10.5 and 12.5 m pole.

Hence, it must be mountable on the vertical section of the street pole.

This position must be between a minimum height of 4 m above the ground level.

And, at least a height of 1 m just below the outreach joint.

5. Cable Port

The cable entry openings must be round-edged because this will help protect the service cables from abrasion.

The smallest radius should also be at least 5 mm.

How to Mount a Street Light Arm

In this section, I am going to show you how to mount a street light arm.

First, you need to review the installation manual from the manufacturer.

This way, you will install the street light arm faster.

Before you begin the installation process, please confirm the following:

- The manufacturer can supply the street light arms for on-site joining

- The poles and the street light arm have uniform or compatible joints like bolt holes and other fitting features

- Physically and visually inspect the street light arm joints to make sure that the formed joints are tight

Street light arm dimensions

Alternatively, you can follow the manufacturer’s instructions to re-align the joints as per the instructions.

Note that the physical inspections involve rocking and pulling the two sections by hand to identify sections that clearly show a fault line at the joint.

It is the base that supports the street light arm off the ground.

Make sure you identify a suitable compatible height to mount the street light arm.

It should have adequate clearance off the ground to ward off vandalism.

Wedge the joints to prevent rotation during operation or adverse weather conditions such as winds, snow, etc.

The street light arms should also be properly aligned to the road, house, path-ways and cable exits.

You should remember to sling the section of the assembly to ascertain the stability of the outreach lighting arm to maintain the alignment.

Only each street light arm at a time can be mounted to observe the safety and stability of the installation.

After identifying the positions where you want to install the street light arm, mark the top and the bottom section.

Now under strict supervision, join the street light arm to the main lighting pole together by applying compressing force before tightening the joints with bolts.

Accuracy and caution during this exercise will prevent any misalignment during the installation.

· Lifting Procedure

The street light arm should be correctly assembled (join all accessories fittings and sections).

The lifting mechanism should have the ability to lift the entire structure when you’re mounting the street light arm.

You should do this carefully to prevent possible damage to any section of the street light arm, or the lighting bracket arm.

Along the sling for lifting the arm, there should be a safety rope hooked and attached to a firm end.

The purpose of the precaution is to ensure a secure and safe erection procedure during the lifting exercise.

The sling must not be tightly wrapped to the street pole to avoid deformation.

Of course, you should ensure that the hook and safety rope remains in position.

It will secure it throughout the process.

Fixing street light arm

Benefits of Street Light Arm

Streetlight arm comes with some benefits.

You can use some designs to enhance aesthetic beauty.

They enhance the beauty and guarantee better illumination.

LED streetlights

In urban settlements, sufficient street lighting equally increases the quality of life by extending the period in which the evening light diminishes.

A range of activities are as well carried out, thus improving the quality of businesses.

The invention of the street light arm substantially improves road and street safety in global cities even in small towns.

Drivers, pedestrians, and riders can enjoy moving around even late at night.

So, with strategically positioned street light arms, they can go on with their activities even at night.

In residential settlements, the use of street lighting brackets has also improved safety for children who prefer to play at night.

With the street light arm, you may not need to erect a light pole.

For example, if the premises have high walls that border a pedestrian footpath and road network.

The street light arms can still be mounted once the electrical wiring is done. In such cases, you’ll save on light pole expenses.

Conclusion

As you can see, a street light arm plays an integral role.

However, you must choose a high-quality and durable street light arm.

You need to consider both design and material.

And that’s why here at Rax Industry, we offer high-quality and reliable street light arm.

Talk to us today, and our team will be ready to help.

FAQS

What is a street light arm?

A street light arm is an extension on street light poles that helps enhance illumination on outdoor lighting poles.

Apart from the common term street light arm, you can also refer to this accessory as:

- Light pole arm bracket

- Light pole bracket

- Streetlight mounting bracket

- Streetlight bracket arm

- Lighting mounting arm

- Streetlight mounting arm, etc.

How to make a street light arm?

- Designing stage: choose the design and shape of the street light arm.

- Fabricating street light arm: welding steel tube to a flat steel base and thoroughly cleaning the surface.

- Finishing operations: galvanizing street light arms during the production process to improve the service life and durability.

What are the main points when choosing a street light arm?

- Street Light Arm Base

- The material of the Street Light Arm

- Street Light Arm Size

- Fixtures and Fittings

- Cable Port

How to mount a street light arm?

- Identifying the positions where you want to install the street light arm

- Follow the manufacturer’s instructions to re-align the joints.

- Joining the street light arm to the main lighting pole together.

- Applying compressing force before tightening the joints with bolts.

- Accuracy and caution during this exercise will prevent any misalignment during the installation.