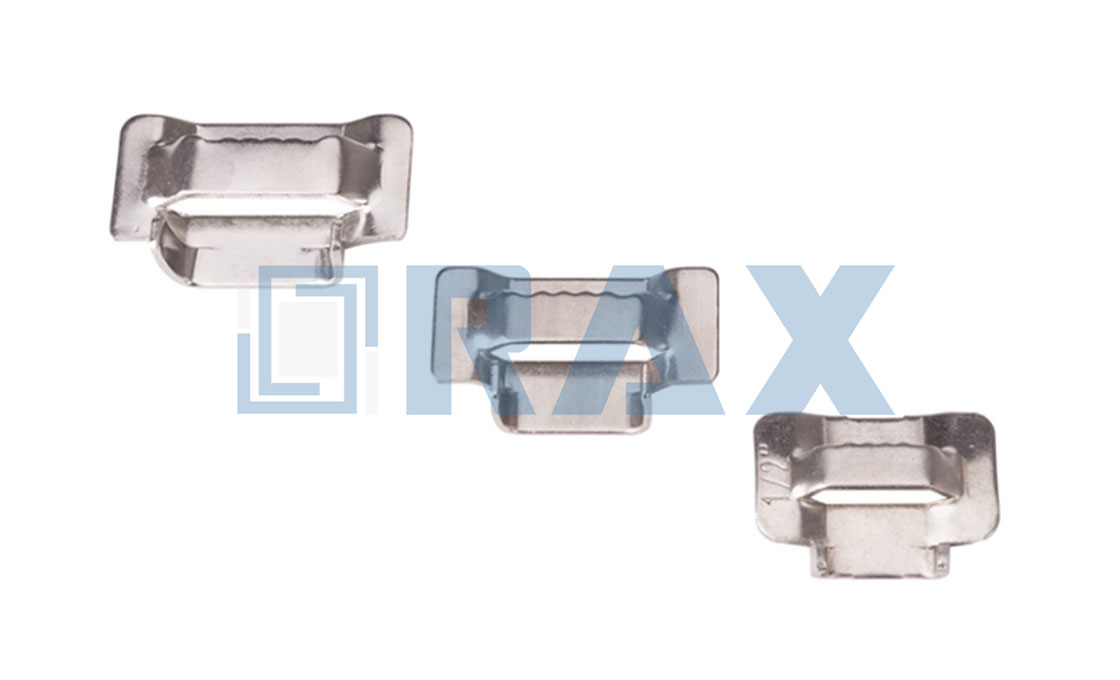

Stainless Banding Buckle

Stainless banding buckles are hardware products used to secure ends together for safer storage or transportation of an item. They are also referred to as stainless steel banding clips.

The two primary applications of stainless steel strapping and banding tools are hose clamping and load securement. Thanks to their strength, they are ideal for heavy-duty commercial and industrial use.

Ideal for all kinds of industries and environments, stainless steel banding buckles offer the most secure way of securement. It is used with other accessories such as;

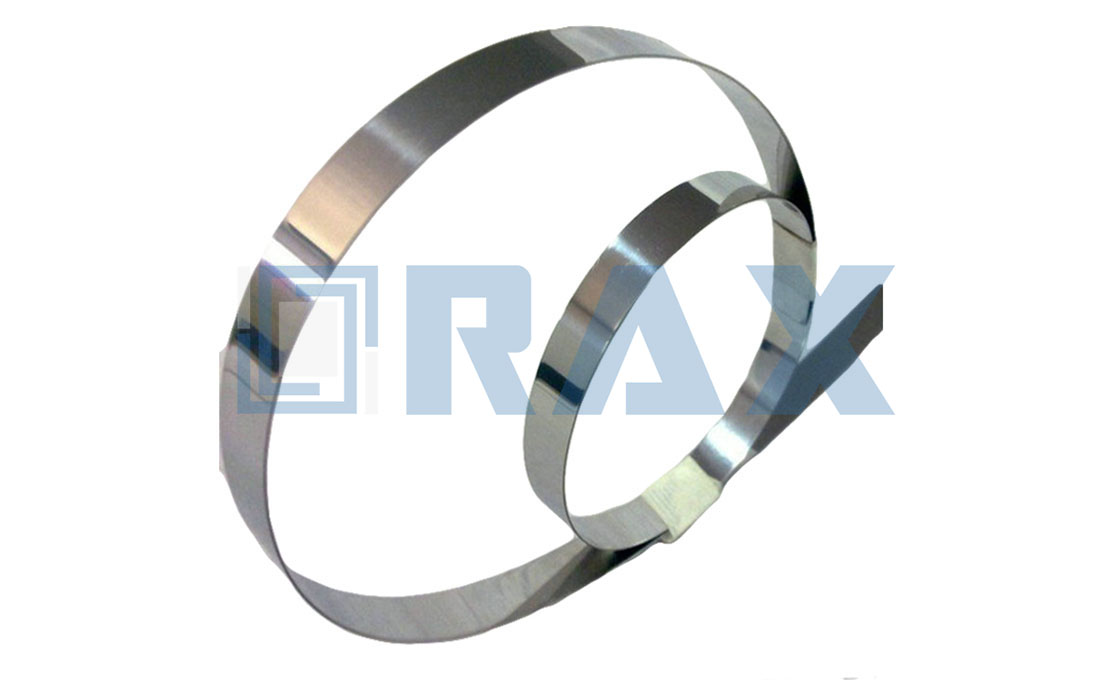

- Banding reels or steel strapping. These come in handy in demanding commercial and industrial jobs. Each reel usually is 335 metres long with varying widths ranging from 13mm, 16mm, and 19mm.

- Sealer tool for crimping seals on stainless steel strapping tool.

- Safety cutting shears for cutting steel strapping (it is utilized on all steel strapping sizes, so you need only one in your kit).

- Tensioner tool used for fastening the strapping.

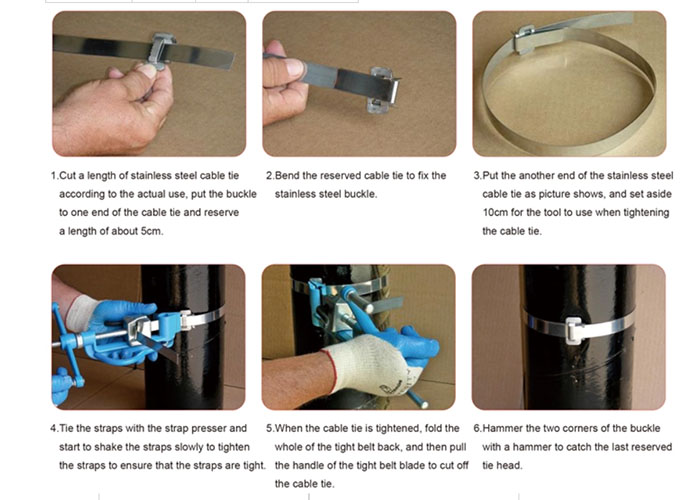

To fix the banding strapping, first, you need to cut it to the right circumference, leaving some extra length. Thread through the buckle and then fold it back on its length. Loop the banding around the item you want to secure and feed the other end back through the banding buckle. Tightly secure it using stainless banding tool and cut, leaving a short piece to tuck back through the buckle.

Rax Industry is a premier stainless banding buckle manufacturer in China, we’re proud to serve companies nationwide, if you have any questions, contact us today.

| Item No. | Width(mm) | Length(mm) | Thickness (mm) |

| Series NO. | Width inches/(mm) | Thickness(mm) | Pcs/bag |

| BK10 | 3/8(10) | 1 | 100 |

| BK12.7 | 1/2(12.7) | 1.2 | 100 |

| BK16 | 5/8(16) | 1.2 | 100 |

| BK19 | 3/4(19) | 1.2 | 100 |

| BK12.7 | 1/2(12.7) | 1.5 | 100 |

| BK16 | 5/8(16) | 1.5 | 100 |

| BK19 | 3/4(19) | 1.5 | 100 |

Features

- Highly durable and versatile

- Its high breaking strength makes it a suitable choice for heavy-duty commercial and industrial applications

- Stainless steel banding buckle offers excellent resistance to corrosion compared to its counterpart plastic banding

- It is available in three main grades, namely, 201, 304, and 316 grades of stainless steel. Your choice depends on where you want to use it, i.e. indoors or subsea

- Stainless steel banding clips offer high resistance to alkalis and acids

The Stainless-Steel Banding Buckles Buying Guide

When poly and plastic won’t do, you have to turn to something much stronger, to tie down steel bands. It could be you need to hold things in place or want to do some repairs. Whatever the reason, you will need stainless steel banding buckles in some of the cases.

These stainless-steel banding clips are suitable for holding loose banding ends together. Sometimes, they are called strapping seals or banding clips.

Banding strap clips are mostly used for:

- Identification

- Bundling

- Banding

- Clamping

You can also use the banding strap buckles in various applications, depending on the width of the banding used or the types of items you would like to strap down.

What is a stainless-steel banding buckle?

Stainless steel buckle suppliers mostly stock the types made out of stainless steel to make sure that they are high-quality and reliable over time. The material used here specifically is made out of different types of metal alloys.

Stainless steel buckle suppliers mostly stock the types made out of stainless steel to make sure that they are high-quality and reliable over time. The material used here specifically is made out of different types of metal alloys.

Stainless steel buckle manufacturers can sometimes have a specific type of metal dominate the composition of the item, depending on the environment where it will be deployed.

Types of Banding Buckles

To understand what you need to use, you need to know the types available. Let’s take a look at each:

Open Strapping Seals

Normally, these are used for steel strapping and poly strapping. They are the most common kind of buckle you will find and are used to maintain strap alignment before applying tension with the proper strapping band tool. The seals are made using galvanized steel and can work with metal strapping between 3/8 and 2 inches.

Normally, these are used for steel strapping and poly strapping. They are the most common kind of buckle you will find and are used to maintain strap alignment before applying tension with the proper strapping band tool. The seals are made using galvanized steel and can work with metal strapping between 3/8 and 2 inches.

The three styles of open strapping seals are; open, thread-on, and semi-open. There could be texturing or serration in the interior for a better grip for some of the poly strappings, especially when tightening with a banding strap tool.

Closed/Pusher Strapping

When securing things like round or irregularly-shaped packages like coils, pipes, and others, you will need this strap. The strap is forced through the seal, forming a slip loop that can be pulled by hand around the package.

Then, it is tightened using a tensioner (*and secured with a notch sealer. This type is made using galvanized steel and is best used with metal strapping between 3/8 and 2.25 inches in width.

Screw Buckles

As the name implies, this type uses screws to hold everything in place. They are used with stainless steel banding straps and can be installed without stainless steel banding tool. The screw buckles are made available in ¼ inch and ¾ inch options.

Magazine Seals

Typically, these seals are stacked together and permit loading stacks into magazines of seal feeding tools. The best use for them needs you to add banding tools for stainless steel bands and power strapping machines to the mix.

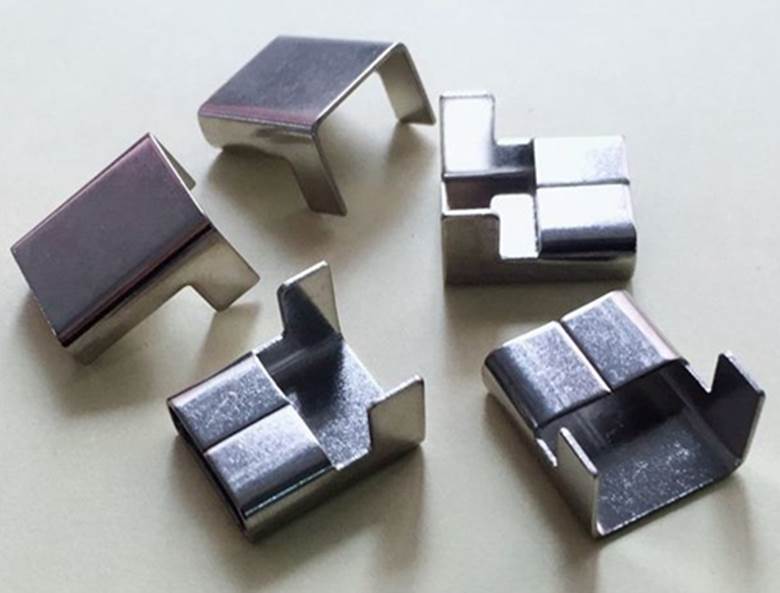

Wing Seals

When working with light gauge metal strapping, wing seals are the way to go. They are made using aluminium, stainless steel, or galvanized steel. They can accommodate straps that range from 3/8 inches to ¾ inches.

Closing them is easy because you can do it with a hammer on any surface or position without needing banding tools with steel bands.

That means they work well with unusual shapes.

Wire Strapping Buckles

With wire strapping buckles, tensioning can be done using no stainless banding tools at all. The materials used are stainless steel, phosphate-coated steel, or galvanized steel. Wire buckles work well with strapping that is ½ inches to 1 ½ inch wide.

You can get heavy-duty wire buckles that are made out of heavy gauge wire.

How Are Stainless Steel Banding Buckles Used?

First off, you will need a stainless-steel banding kit, but not always. It depends on what you are working with. Make sure to read the banding buckles instructions to find out what you need to do to get the best results.

First off, you will need a stainless-steel banding kit, but not always. It depends on what you are working with. Make sure to read the banding buckles instructions to find out what you need to do to get the best results.

When working with a banding tool for stainless steel bands, the best practice is to ensure that you are safe from any potential slipping or accidental unraveling.

With the banding strap tool, you can fasten the buckles after inserting the loose banding ends through them.

Conclusion

When picking out the best kinds of stainless-steel banding buckles to use, your focus should be on quality and the bands it is capable of holding together. Our extensive catalogue contains various types of buckles to ensure that we can help you fasten any of your bands.

Remember to assess the kind of work you are going to do and ensure that you have the proper stainless steel strapping tool where required.

Feel free to look through what we offer and find what works best for your specific needs.

FAQ

Stainless banding buckles are hardware products used to secure ends together for safer storage or transportation of an item. They are also referred to as stainless steel banding clips. Stainless banding buckles are ideal for heavy-duty commercial and industrial use. There are two primary applications: hose clamping and load securement.What is a stainless banding buckle?

What is the application of stainless banding buckle?

Types of stainless banding buckles

Features of stainless banding buckles