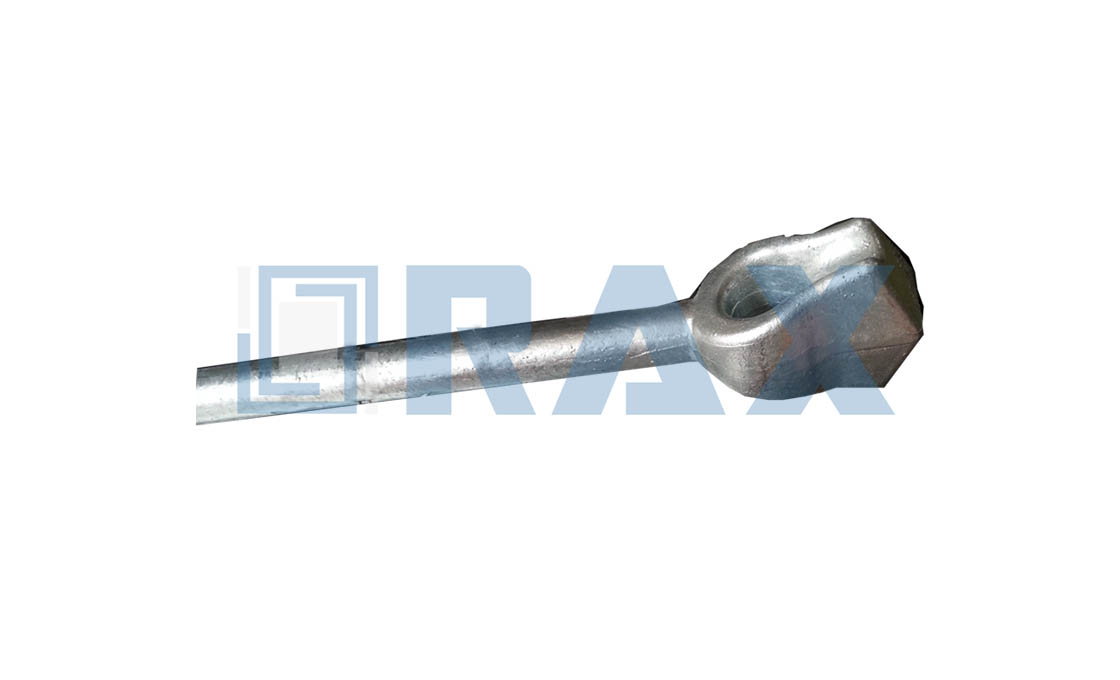

Anchor Rod

The anchor rod is an important component for utility and telephone poles, it is also called guy anchor rod, guy wire anchor rod, thimble rod, or thimble eye anchor rod.

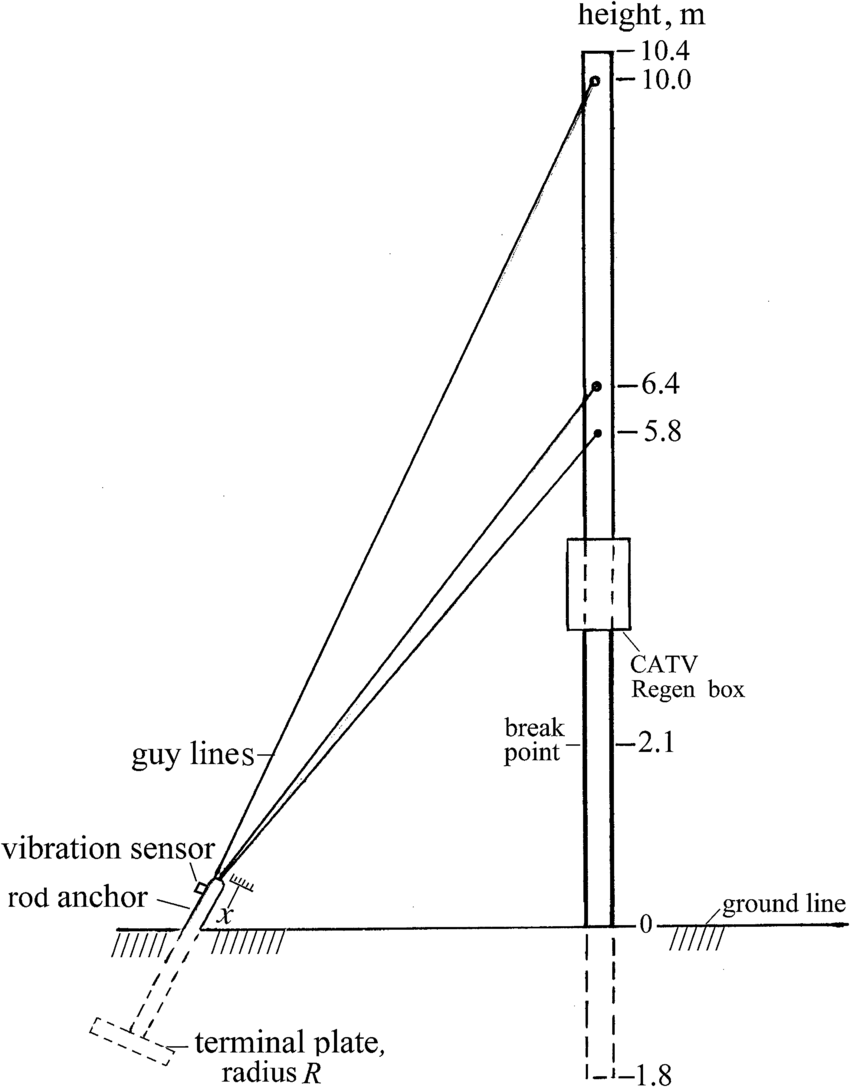

One end of a guy anchor rod is connected to a stay wire by a guy clamp, and the other end is fixed to types of earth anchors buried under the ground. This design is to make the line pole fixed on the ground firmly by the guy wire anchor up pull strength.

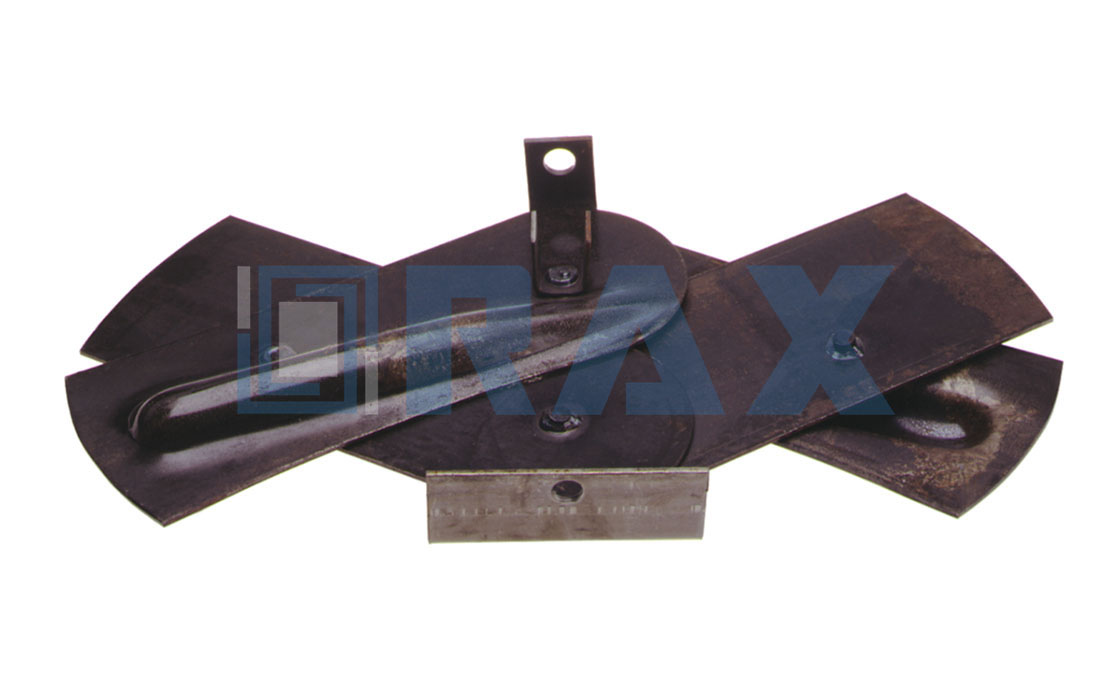

According to the design, there are rods for cross-plate anchors and expanding anchors, rods for manta ray anchors, no-wrench anchors, and rock anchors.

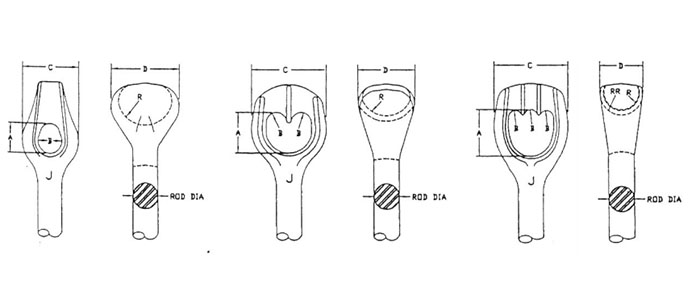

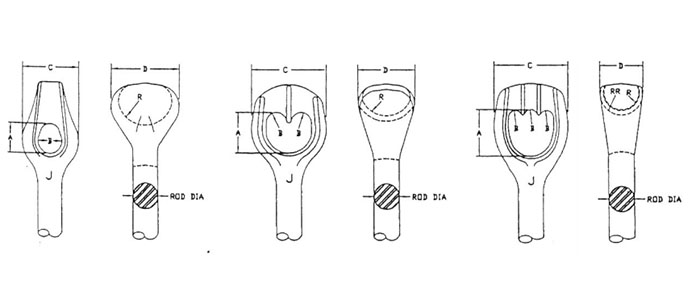

The anchor rods are dropped forged to single, double, or three-strand eyes. The alternative anchor rods are furnished with oval eyes together with an equivalent number of wire strand thimbles. All thimbles size accommodates the size of the stay wire strand.

The anchor rod has a strong and durable physical property to withstand storms and disasters. To ensure the safety and steady of the pole line, it’s important to use a high-quality anchor rod to install the overhead power lines.

Part of the anchor rod that easily gets rusty is 30cm to the ground and 50cm under the ground. Considering it easily gets rusty to bury the anchor rod under the ground, the diameter is usually 2-4mm bigger.

The main process of making the guy anchor rods is hot forging. Rax Industry uses a high-frequency furnace to heat the rod until it turns red, and then polish the iron oxide. Finally, punch the red-hot metal head into a double eye or thimble eye shape. The surface treatment of the anchor rod is hot-dip galvanization to protect the anchor rod from getting rusty even during rainy and salty conditions.

Rax Industry has produced the thimble eye anchor rod for more than 10 years and is ready to increase your volume in your market.

Rax Industry has four lines in making the thimble eye anchor rod, so in most cases, we can ship the container anchor rod to you in a short time. Even if your design is customized, Rax Industry’s able and knowledgeable workers will help you finish it in time.

To know more about the anchor rods, please contact us now.

Guy wire anchor rod feature:

Guy wire anchor rod feature:

1. Breaking Load test: 62kn for 1 min

2. Hot-dip galvanized strictly according to ASTM-123

3. Uniform and reasonable packing

4. Size Accuracy 0.1mm.

5. Direct From Factory, Save 30%–50% Cost

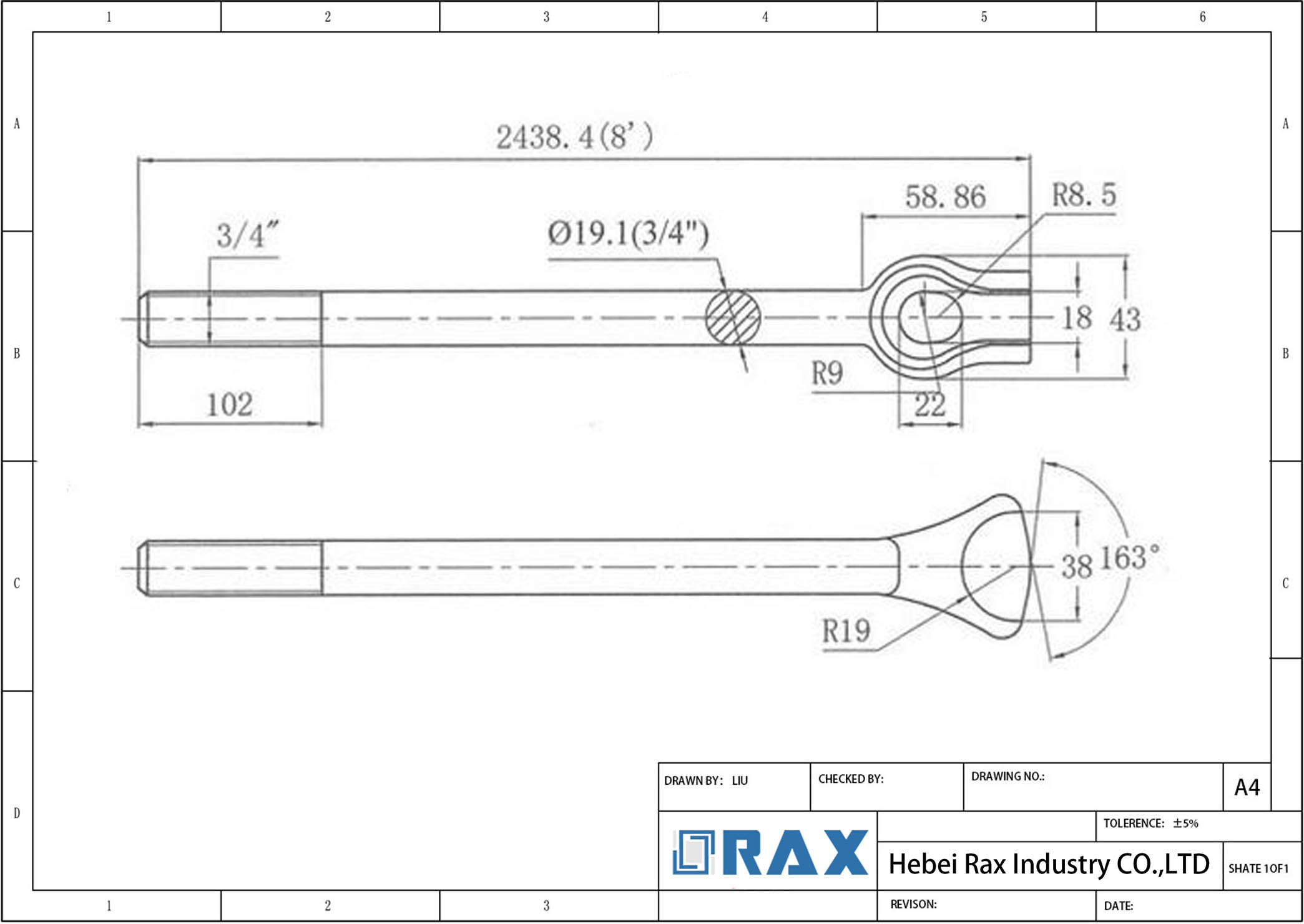

The guy wire anchor rod with square nut is manufactured in hot-dip galvanized steel. The raw material steel is selected according to AISI-SAE 1018 or 1020. The carbon is not lower than 0.13% according to ASTM A36M. Zinc coating of 80 um, according to ASTM A-153. The head of the guy wire anchor rod will be forged in one single piece with a single eye, twin-eye, or trip eye as attached drawings.The other side rod is with 8cm to 10cm thread length according to UNC. The UNC required 10thread per inch.

The heavy-duty square nut which assembled on the guy wire anchor rod is of galvanized steel with a minimum coating of 53 um, according to class C of ASTM A153. The square nut thread is made before galvanization.

| Item | Length | Dia. | Minimum strength | Thread length | Yield strength |

| Single eye thimble rod | 8’or 6’ | ¾” | 106kn | 89mm UNC | Minimum 345 Mpa |

| Twin eye thimble rod | 8’or 6’ | ¾” | 106kn | 89mm UNC | Minimum 345 Mpa |

| Trip eye thimble rod | 8’or 6’ | ¾” | 106kn | 89mm UNC | Minimum 345 Mpa |

Anchor Rod Packing

Guy Wire Anchor Rod: The Complete Guide

Anchor rod is a must-have accessory when installing a pole line for distribution or transmission.

More importantly, you must choose high quality, durable, and reliable anchor rod.

A reason why I want to walk you through the nitty-gritty of this accessory.

It is a short guide that covers all these basics – definition, designs, classification, specification, installation process, etc.

Keep reading to learn more.

- Chapter 1: What are Anchor Rods?

- Chapter 2: Application of Anchor Rods

- Chapter 3: Types of Anchor Rods

- Chapter 4: Technical Specifications of Anchor Rods

- Chapter 5: Anchor Rod Fabrication Process

- Chapter 6: Installation of Anchor Rods

- Chapter 7: Reliable Guy Anchor Manufacturer in China

- Chapter 8: Conclusion

- Chapter 9: FAQ

What are Anchor Rods?

Anchor rods are also referred to as anchor bolts, thimble rod, guy anchor rods, or thimble eye anchor rods.

They are used to connect non-structural and structural elements to the ground or the concrete.

Anchor rod

It comprises an assembly of different products including steel plates, anchor bolts or fasteners and stiffeners.

Apart from the above-listed components, anchor rods come in quite a number of forms.

These include:

Power line Anchor

It is a tension cable designed and used to increase stability to a structure standing freely.

They can be seen in common use in radio masts, ship masts, utility poles, tents, and wind turbines.

It can also be referred to as a guy rope, guy wire, or a guy line or in simple words “guy”.

Utility Pole Anchor

Utility pole anchors, posts, or a column that is used as support for power lines and other utilities.

It is usually attached to the pole where the eye nut and the anchor rod are completed at the factory.

It is used with the socket drive or the solid hub screw anchors.

Guy Wire Anchor Rods

It is also a wire that is mostly used to anchor and increase stability to free-standing structures.

The function of the guy wire is not different from the function of the power line anchor.

Can be used in fire service extension ladders, church raises, and can also be known as a guyed mast.

Application of Anchor Rods

Anchoring wood to the foundation – concrete structures are usually very strong but wood structures require additional support.

It is usually attached to concrete foundations using anchor rods to avoid any movements.

Special anchor rods are used in areas that are prone to earthquakes and earth movements.

Load transference – it helps in the uniform distribution of load to prevent collapse.

This is because there is quite a lot of weight on the vertical and horizontal structures.

The anchor rods transfer the weight to the foundation of the building and not to the frame of the building.

Tethering – mounting a structure that is not allowed to move will require the use of an anchor bolt.

It requires the use of special anchor bolts with hooks that increase the stability of the mounting structure.

Types of Anchor Rods

There are many types of anchor rods and they include:

Anchor rod

Anchor rod

Cast in Place

It is known to be the strongest and the simplest form of anchor rods anybody can use.

It consists of an embedded end used in composite structures of steel as shear connectors.

It can also be used to anchor machines and other things such as buildings to concrete floors permanently.

Post – installed

These anchor rods are installed at any point of the concrete structure provided a hole has already been drilled.

The difference is seen when the anchor rods have been put in place to perform different functions they are meant to perform.

Furthermore, whenever you’re dealing with anchor rods, you should note the following:

i. Mechanical Expansion Anchors

This mechanism is based on friction which helps in transferring the expansion force to interlock the anchor rod.

It is divided further into two categories which include torque controlled and displacement controlled mechanical anchors.

ii. Undercut Anchors

The force that is transferred to the interlock depends on the mechanical interlock.

An operation for drilling the concrete creates a contact surface between the wall holes and the anchor head.

At this point, there is an exchange of the bearing stresses to make it effective.

iii. Bonded Anchors

The mechanism involved depends on bond stresses that are provided by bound organic material.

In this case, threaded rods and ribbed bars can be used and can also be known as adhesive anchors.

iv. Screw Anchors

The mechanism used in this process depends on pressure bared in concentration between concrete and screw pitches.

v. Plastic Anchors

The mechanism involved is not different from that of the anchors depending on mechanical expansion.

The torque moment can be applied to the screw inserted in a sleeve made of plastic.

vi. Powder Actuated Anchors

It acts by transferring the force through mechanical interlocks.

The mechanism is usually used in the steel to steel type of connection.

Technical Specifications of Anchor Rods

Before you buy an anchor rod, it is important to pay attention to the following:

Technical specification of anchor rods

Type of material

Anchor rods are made of steel which varies in terms of strength and durability.

The strength of the steel used ranges from “Mild steel, Medium-strength mild steel, high strength steel, and alloy steel”.

The steel is tested to make sure that it fits the standards required of it and a certificate is issued.

The material has to be strong enough to withstand the harsh weather conditions of the place it is used.

The same applies to the kind of work it is expected to perform and the temperature ranges of the said area.

Tensile Strength

Strength of material used in making anchor rods depends on the diameter of the material described as pounds per square inch.

It is important to know the strength of a particular product and the pressure it will hold before fabricating.

The anchor rod is expected to withstand the pressure it was intended to.

Quality Compliance (ASTM A153, ANSI/IEEE)

Anchor rods are manufactured to adhere to quality compliance – ASTM A153thus ensuring material safety for use.

This act requires compliance from nuts, metallic bolts, screws, and studs to ensure that high-quality products are used.

Consumers are protected by this act giving them the right to have access to quality products.

Weight

The weight of the anchor rod is also purely dependent on the kind of job it will be subjected to.

At this point, anchor rods of high quality are usually heavier so that they can perform tasks that exert high pressure.

The heavier the anchor rod, the higher the quality.

Dimension

Dimensions of anchor rods are often determined by certain machines and by engineers.

These people investigate the kind of work an anchor rod is to be subjected to before giving the right dimensions.

Hardness

Anchor rods are very hard materials in relation to the kind of task they are subjected to.

The hardness of the anchor rod usually dictates the strength of the material.

A strong and hard anchor rod is quite durable and can be used for quite a while.

Anchor Rod Fabrication Process

Anchor rods are fabricated in quite a number of configurations usually specified by engineers.

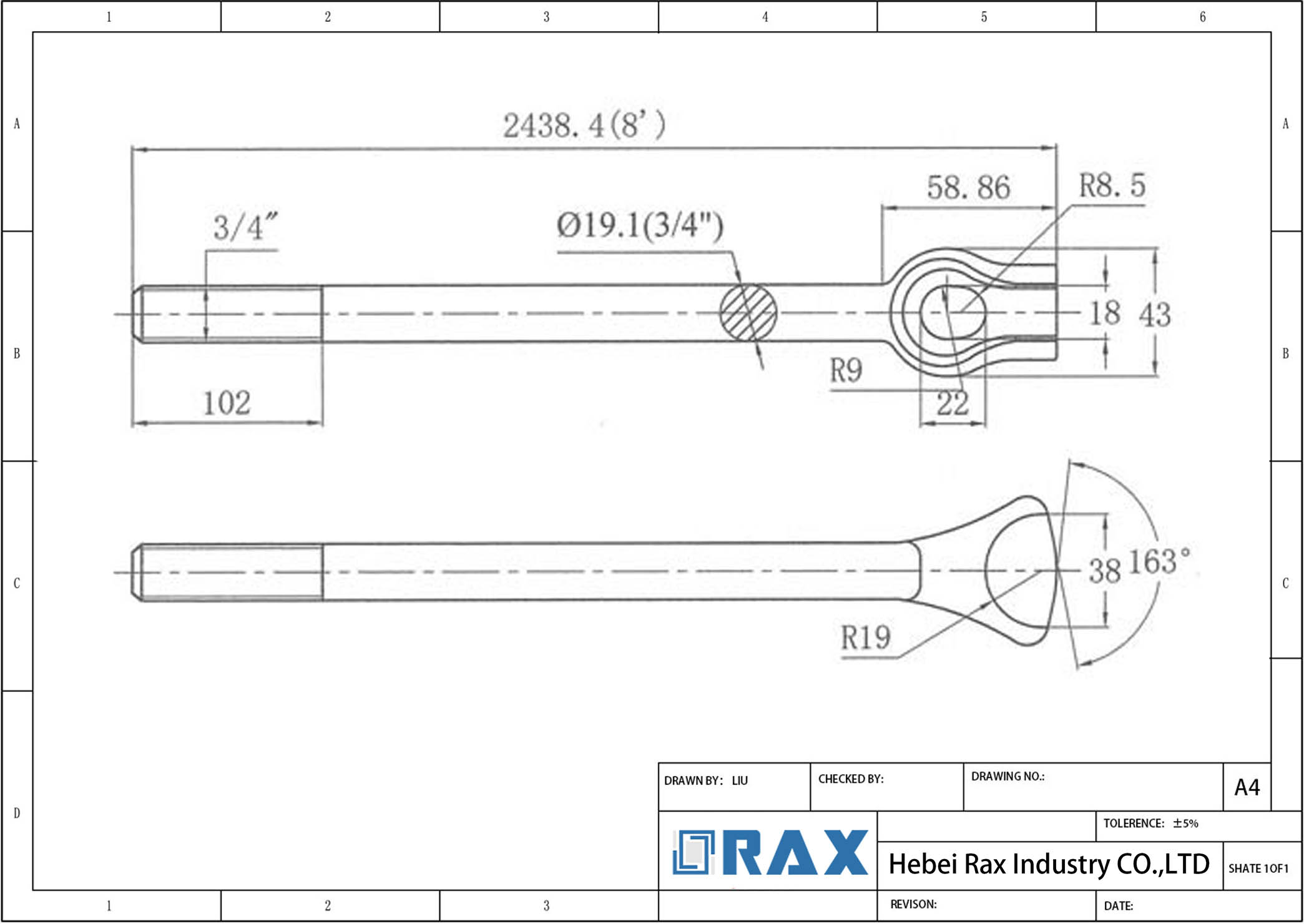

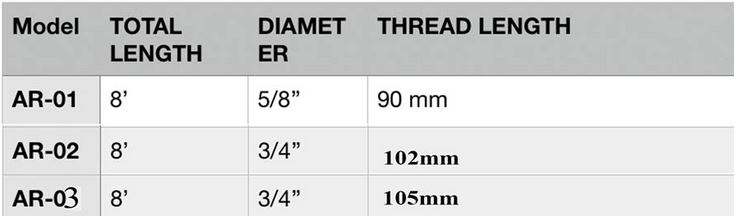

Technical drawing of an anchor rod

Configurations used usually covers the size and grade of anchor rods based on application and forces that will act against it.

- Steel bars are cut to length, then heated at very high temperatures to melt before being rolled.

- Regardless of the configuration of anchor rods, it has to be threaded at one of the ends.

- Threading is done by either cutting using chasers or rolling through the process of extrusion.

- Heading the anchor rods is the next process but this does not apply to all the anchor rods. The head is supposed to create pull-out resistance on the anchor rod.

- The end which is not threaded is heated at around 2000 degrees and molded into a head.

- Bending anchor rods at a right angle is done to produce a hook that will be embedded in the concrete. It is done by heating the steel at very high temperatures to make it flexible for easy and precise bends.

- The anchor rod is then swedged by pressing large dimples on the side that was embedded.

- Chamfering is the application of a slight bevel to the end that is threaded to help in installing the galvanized nut.

- Welding anchor rods are also done on the embedded end to bind the molten steel with a filler.

- The next step is plate fabrication where round, square or rectangular plates are joined to the embedded end. This is done to provide the anchor rod with a pull-out resistance.

- After that, the anchor rod is heat-treated to quench and treat it so that it can attain the required tensile strength.

- To provide a smooth finish the anchor rod is hot-dip galvanized by submerging it into molten zinc. Galvanization is done to provide the anchor rod with a resistance coating to corrosion.

Installation of Anchor Rods

Anchor rods go through quite a number of processes as it is being installed for use.

Anchor rods with threads and nut

Anchor rods with threads and nut

Remember that the installation process will vary according to the kind of job you are doing.

A professional is expected to be around to do the job if you are not experienced enough.

- During concrete placement, the anchor rod is to be held strictly in the same position it is expected to be.

- Anchor rod threads are required to be coated by lubrication on special occasions such as roadway illumination poles.

- After that, the anchor rod is tightened using a template that will be removed once the job is done.

- Do not forget to place the washers before erecting the structure that is supposed to be placed on the rods.

- Make sure the erected structure is in place before placing another washer through the rod threads and a bolt.

- The bolts are then tightened to make sure that the structure is held firm and cannot be moved.

Reliable Guy Anchor Manufacturer – Why customers choose us

Quality control

Rax Industry workers will do the second time selection based on the standard ASTM A123, All the defects thimble rod will be selected to do the amending and galvanized again.

The detailed standard for the worker to execute is as below:

1.Zinc coating below standard requirement (minimum 86 um at any part of the rod)

2.When sizes are out of the sizes indicated in this order.

3.Pieces bent, broken, cracked, or a way different to described between the thimble rods

After the second time selection, the QC team will do the inspection. The QC team will select 50 pieces at random and will check all the specifications and if 6 pieces show any defects, the thimble rod will be stopped shipping.

First-rate service: Packing and Storage

Rax Industry guy wire anchor rods are buckled of 10 units, with properly reinforced strapping tape metal bands or steel wire. And 20 buckles are packed in 1 woven/steel pallet. In this way, Rax Industry thimble rods will be packed and secured to ensure transport and storage.

Conclusion

I hope at this juncture, you can now buy a suitable anchor rod for your pole line system.

You must consider the design, quality specification, fabrication, and of course, the anchor rod manufacturer.

At Rax Industry, we strive to give you the best designs of anchor rods.

Talk to us today, and we will help you get the best anchor rod.

FAQ

What is a guy wire anchor rod?

The guy wire anchor rod is an important component for fixing utility and telephone poles. One end of a guy anchor rod is connected to a stay wire by a guy clamp, and the other end is fixed to types of earth anchors that are buried under the ground.

Guy wire anchor rod is also called guy anchor rod, guy wire anchor, or thimble anchor rod.

What are the types of guy anchor rods?

According to the rod head, there are one thimble eye anchor rods, twin-eye anchor rods, and trip eye anchor rods.

What’s the difference between the guy anchor rod and anchor bolt?

Anchor rod VS anchor bolt:

The anchor rod is usually used to make the line pole fixed on the ground firmly by the guy anchor up pull strength.

The anchor bolt is a fastener used to attach objects or structures to stone, concrete, and masonry.

Which type of earth anchors are usually used with guy anchor rod?

There are main 3 types of ground anchors:

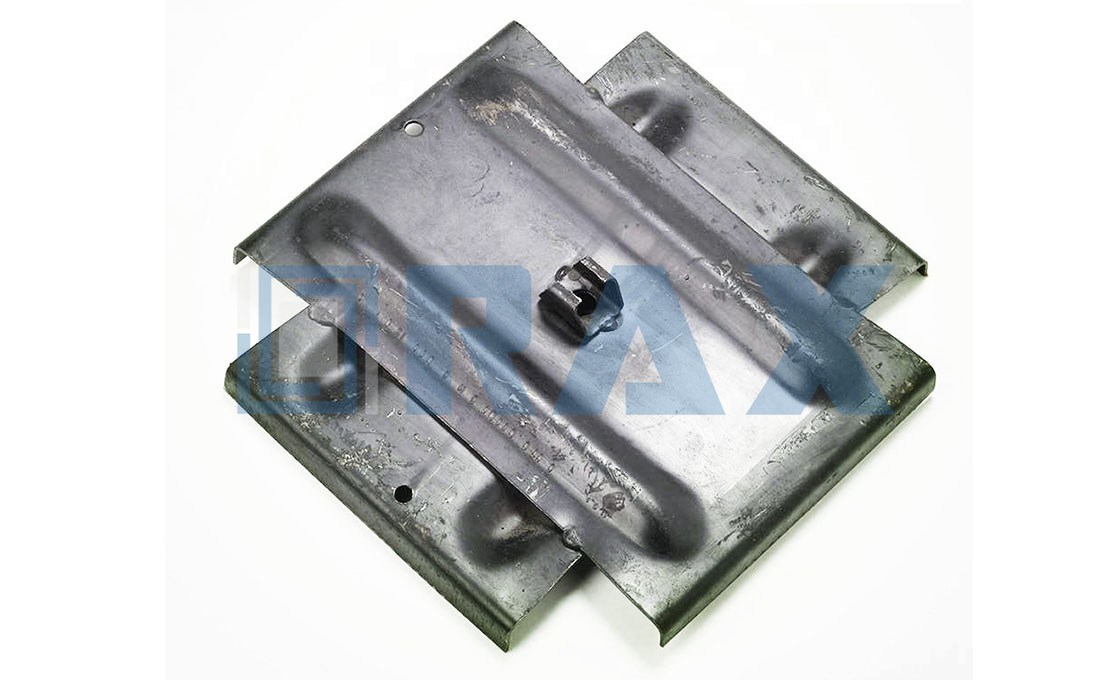

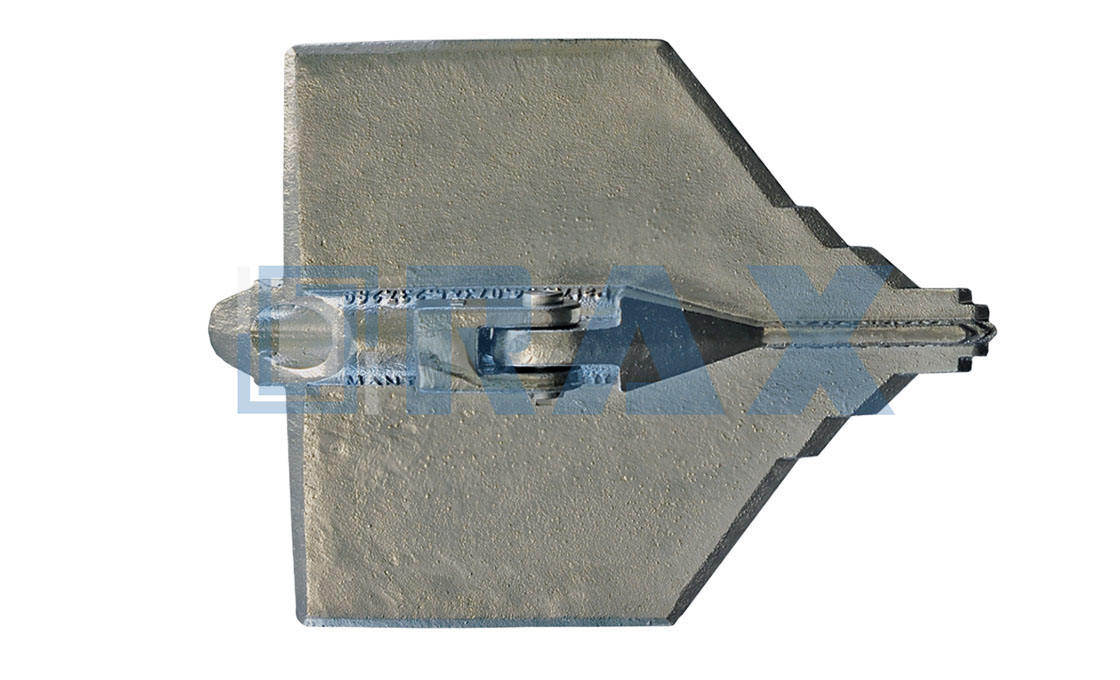

- Expanding Anchors

- Cross Plate Anchors

- Pole Key Anchor