Expanding Rock Anchor

Rock anchor is installed into the unweathered rock to develop the full strength and stability of the anchor rod.

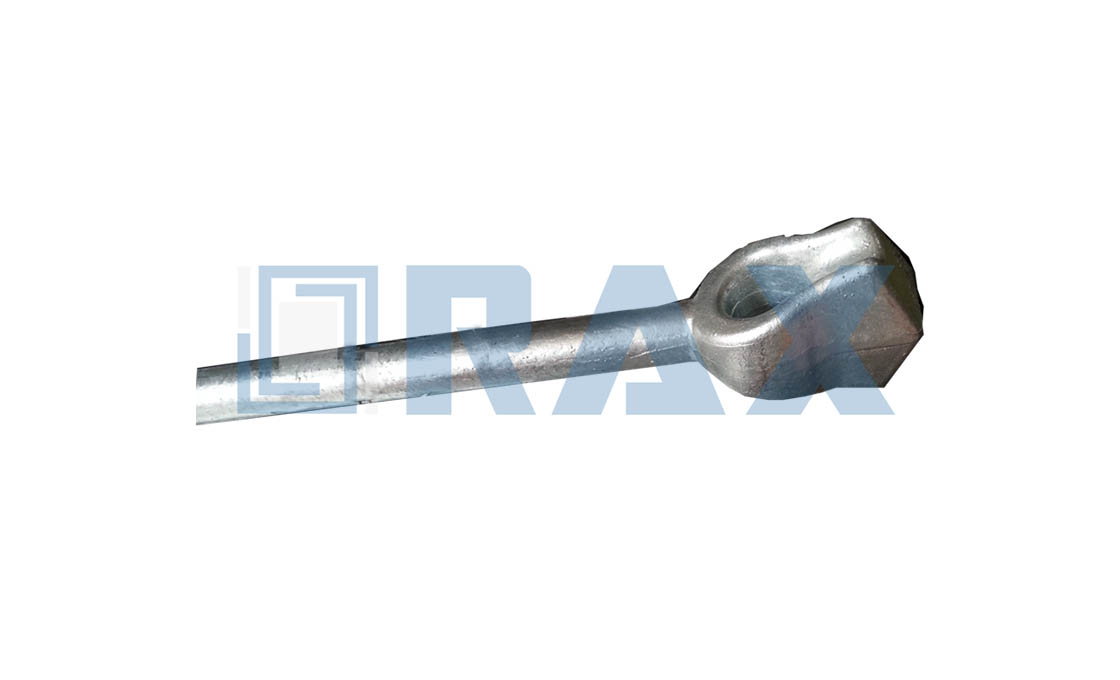

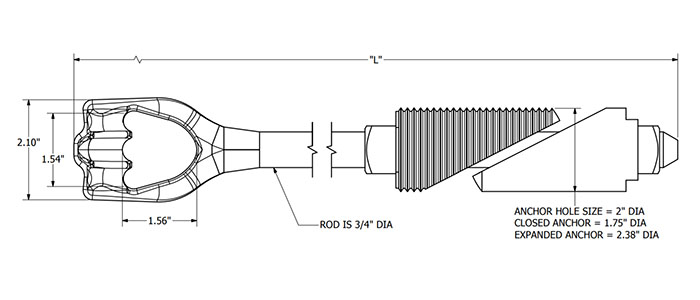

The rock anchor features triple eyes that provide space for up to three guy connections. A hole of the specified size is drilled into the rock and it should be in line with the angle of the guy. The rock anchor is inserted and a bar that passes through the eye turns the rod.

The eye grooves of the rock anchor are contoured to prevent the guy strands from kinking, bending, or even spreading.

The good thing about rock anchor is it does not require a wrench for the installation. The design of the anchor gives allowance for self-installation.

The ability of the anchor to bore through rocks also helps to save time and the cost of labor that is required for the boring process. When it comes to drawing a comparison, the cost of installing rock anchor is way lesser than that of installing through the grouting method.

Rock anchor is galvanized according to the ASTM A123. Its wedges are coated with a rust inhibitor which ensures that it lasts for long regardless of the environment of the installation. It also has high tensile strength that makes it withstand all sorts of forces.

| Model | Rod Diameter Inches (cm) | Rod Length Inches (cm) | Anchor Size Closed Inches (cm) | Anchor Size Exposed Inches (cm) | Hole Size Inches (cm) | Weight Lbs (kg) |

| R3415 | 3/4 (1.9) | 15 (38) | 1-3/4 (4.5) | 2-3/8 (6) | 1-7/8 (4.8) | 5 (2.3) |

| R3430 | 3/4 (1.9) | 30 (76) | 1-3/4 (4.5) | 2-3/8 (6) | 1-7/8 (4.8) | 7 (3.2) |

| R3453 | 3/4 (1.9) | 53 (135) | 1-3/4 (4.5) | 2-3/8 (6) | 1-7/8 (4.8) | 10 (4.5) |

| R1030 | 1 (2.5) | 30 (76) | 2-1/4 (5.7) | 3-1/8 (7.9) | 2-3/8 (6) | 14 (6.4) |

| R1053 | 1 (2.5) | 53 (135) | 2-1/4 (5.7) | 3-1/8 (7.9) | 2-3/8 (6) | 18 (8.2) |

| R1072 | 1 (2.5) | 72 (183) | 2-1/4 (5.7) | 3-1/8 (7.9) | 2-3/8 (6) | 24 (10.9) |

| R1096 | 1 (2.5) | 96 (244) | 2-1/4 (5.7) | 3-1/8 (7.9) | 2-3/8 (6) | 29 (13.2) |

| R3460 | 3/4 (1.9) | 60 (152) | 1-3/4 (4.5) | 2-3/8 (6) | 1-7/8 (4.8) | 11 (5) |

| R3472 | 3/4 (1.9) | 72 (183) | 1-3/4 (4.5) | 2-3/8 (6) | 1-7/8 (4.8) | 12 (5.4) |

| R3484 | 3/4 (1.9) | 84 (213) | 1-3/4 (4.5) | 2-3/8 (6) | 1-7/8 (4.8) | 13 (5.9) |

| R3496 | 3/4 (1.9) | 96 (244) | 1-3/4 (4.5) | 2-3/8 (6) | 1-7/8 (4.8) | 15 (6.8) |

Rock Anchor Complete Buying Guide

In the world of civil engineering, you will encounter and use different types of ground bolts or ground anchors. These are devices that are used for transmitting forces to the soil using their tendons. In doing so, they support different structures to the ground by preventing the slopes from collapsing. One of the popular ground bolts is the rock anchor. In this complete guide, We’re going to dig deep into ‘rock anchor‘, you can jump to any section that interests you:

- Chapter 1: What is a rock anchor?

- Chapter 2: How does a rock anchor work?

- Chapter 3: What are the applications of the rock anchor?

- Chapter 4: How to install a rock anchor?

- Chapter 5: What is the difference between a rock anchor and a rock socket?

- Chapter 6: Advantages of rock anchors

- Chapter 7: Rock anchor manufacturer

What is a rock anchor?

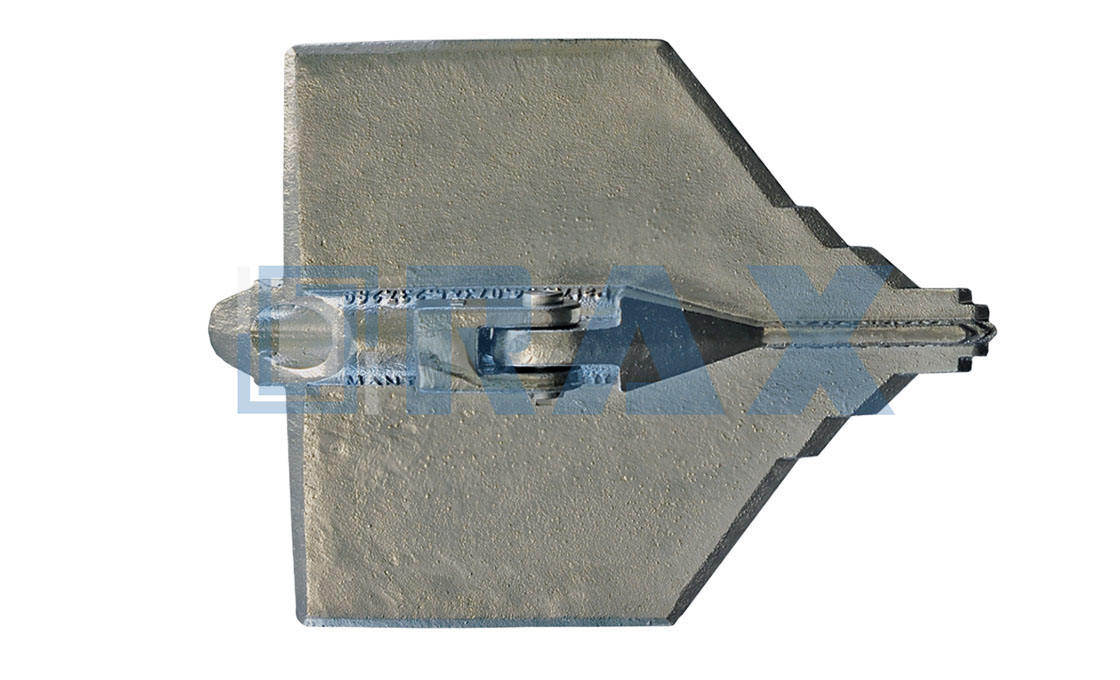

Rock anchors are designed to counteract uplift forces that are acting on the foundation which is supporting the existing concrete structures. A rock anchor has proven to be the ultimate solution for the foundation problems. In most applications, the anchors are tensioned to a force that is higher than what is needed to offer maximum resistance against the uplift forces emanating from the ground.

Rock anchors are designed to counteract uplift forces that are acting on the foundation which is supporting the existing concrete structures. A rock anchor has proven to be the ultimate solution for the foundation problems. In most applications, the anchors are tensioned to a force that is higher than what is needed to offer maximum resistance against the uplift forces emanating from the ground.

When no tension is applied, the device will simply be known as the rock bolt. This is because it will be playing a minimal or even no anchoring role on the foundation. Either way, both the rock anchor and rock bolts are grouted to their full length. The only difference is rock anchors are grouted in two steps to give allowance for the free tensioning.

How does a rock anchor work?

The working mechanism of anchor rocks entails holding down the mass of rock together before it loosens or disintegrates due to the uplifting pressure from the ground. Unlike the anchor bolts, rock anchors are held tightly by the masses of rocks surrounding the device. This means that the pull-out strength does not affect the normal operation of the device.

The working mechanism of the rock anchor helps to minimize the chances of rockfall or disintegration of the concrete. The high tensile steel metal of rock anchor provides the required strength.

A rock anchor may feature a stranded cable or a tensile bar that provides the tension piles whenever the soil covering the rock is not enough.

What are the applications of the rock anchor?

As we have stated, rock anchors are mainly used in most civil engineering projects. The most common application areas of these supporting devices include;

-Mining and refinery areas where they secure the surface and the tunnels from the effects of wind and moving machines

-Bridges: Here the anchors are mostly used for providing the tiebacks that are on the bridges

-Building and construction.

Is there any other project that you think a rock anchor will be of importance? Consult the experts and they will give you the necessary guidance.

How to install a rock anchor?

After buying a rock anchor, the next step is to proceed with the installation. Here are the steps for installing a rock anchor:

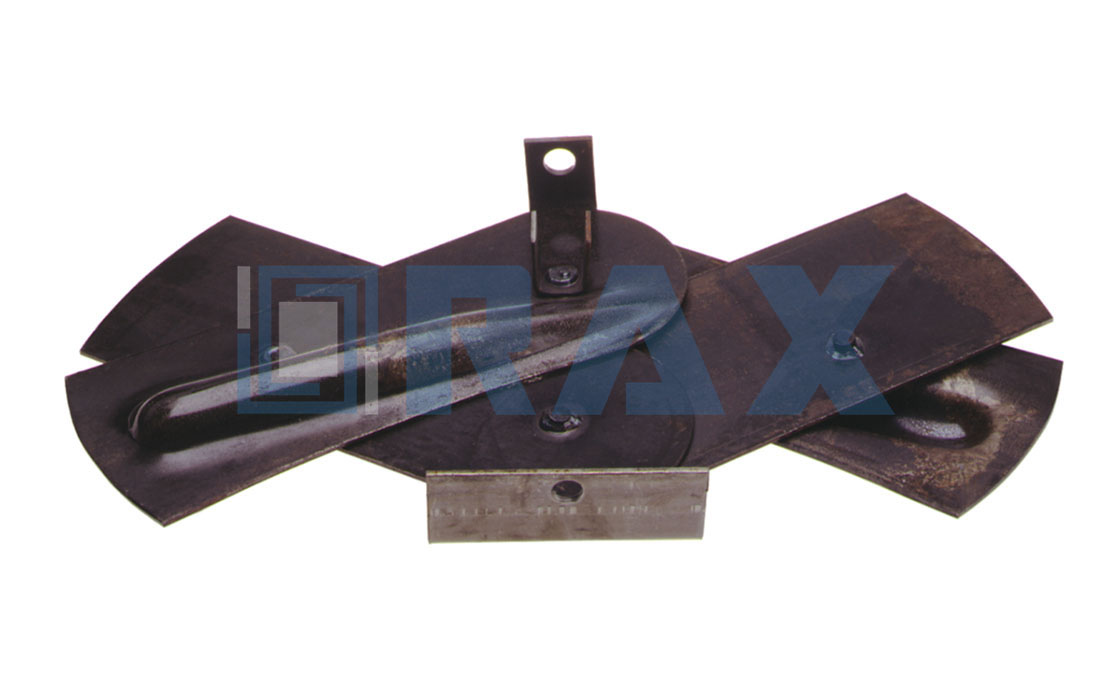

Step 1: Drill the Hole

The first step is to drill a hole whose diameter is equivalent to that of the rock anchor. The depth of the hole should also match the length of the rock anchor. The high levels of accuracy that is needed means that you should get the most advanced drilling machines.

During the drilling, it is vital to consider the issue of alignment. The hole should be properly aligned. The optimal diameter difference between the hole and the anchor should range between 4mm and 10mm.

Step 2: Inject the Grout

Before you inject the grout, ensure that you clear the drill hole to remove any traces of debris. You can then proceed to fill the hole with the grout. However, you should leave out a small space at the top of the anchor hole. This will provide room for expansion.

Step 3: Insert the threaded rock anchor

Insert the sheathed threaded anchor down the grouted anchor hole. Ensure that it goes down to a depth that will leave the desired length that you want to work with sticking out. The function of the sheath is to prevent the threaded anchor from bonding with the grout. Once the anchor is in a perfect position, you can remove the sheath.

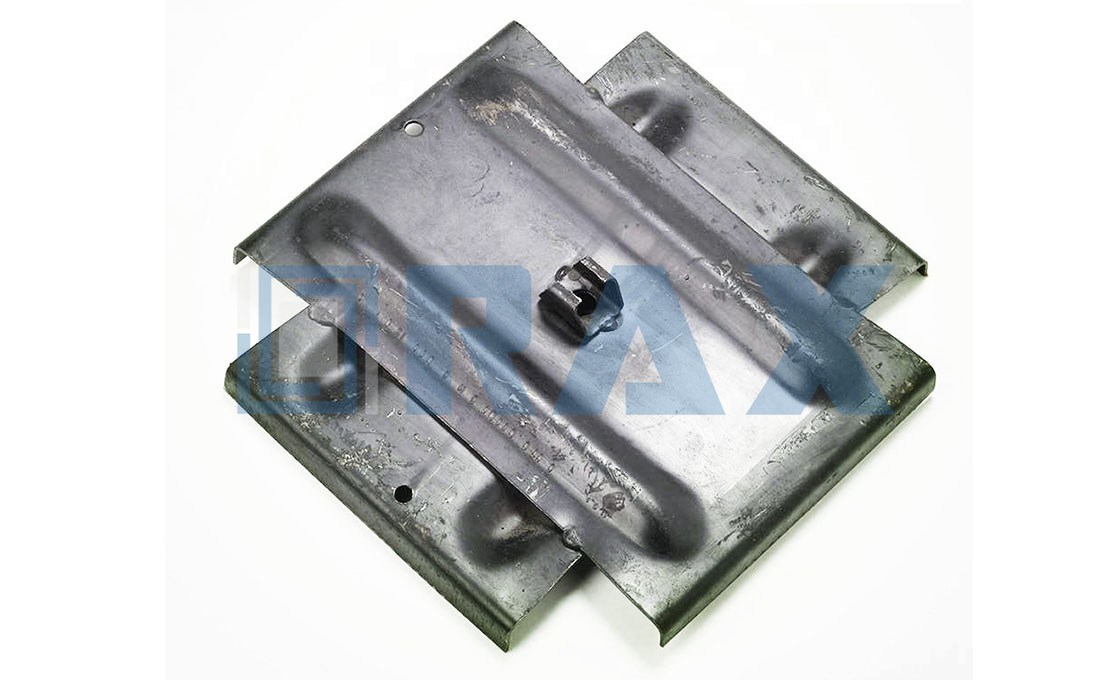

Step 4: Install the bearing plate

Proceed to install the steel bearing plate to the part of the rock anchor that is outside the hole. You can then bolt the plate into a perfect position.

Step 5: Tension the anchor

You can now pull the anchor using a prescribed tension and a retaining nut. Lock it well to prevent any cases of future movement. Tensioning gives rock anchors strength and tenacity to withstand all kinds of forces.

What is the difference between a rock anchor and a rock socket?

Another device that is closely associated with rock anchor v is the rock socket. Although these two devices are similar, they have structural and functional differences.

As we have already stated, the primary function of rock anchors is to resist the uplift forces. On the other hand, rock sockets are used for resisting vertical load lateral load.

Advantages of rock anchors

Why should I choose a rock anchor over other devices? There are numerous benefits that you will gain from using rock anchors.

A rock anchor provides a cost-effective solution for reinforcement. The gravity foundation, which is usually used as an alternative to rock anchor is quite expensive to install. With rock anchors, you will not spend a colossal amount of money on the supporting components.

Rock anchors are also easy to install. You will not have to construct reinforced concrete or follow complex installation procedures.

Also, you do not have to excavate large areas to install rock anchors. You only need to drill a small space and you will be through with the installation process.

Rock anchor manufacturer

Are you looking for a strong and high-quality rock anchor for sale? You need to be wary of where you buy. Consider buying from the best rock anchor manufacturer and you will not regret it. Reliable rock anchor manufacturers in China will strive to deliver the best products.