Formed Wire

Formed Wire is also called preformed line, Rax Industry has all classes of formed wires that meet your electrical and telecommunication utility needs. It is hard to underestimate the important roles that the formed wires play in any utility and installation.

Some of the formed wires ensure that the conductors remain stable in their respective positions. Others are used when you want to join the conductor cables. Regardless of the role, you should strive to get the best-formed wires that will perfectly fit its job description.

As an ISO certified manufacturer and supplier, Rax Industry can supply you with types of formed wires:

- Insulator tie (top tie, side tie, and spool tie)

- Dead end grip

- Armor rod

- Suspension clamp

- Line Guards

- Spiral Vibration Damper

- Conductor Splice

Each of the formed wires plays a unique role in a utility. Once you know the kind of action that is needed in your installation, you will pick the appropriate formed wire from the above list. We also manufacture products according to the customers’ specifications.

Reliable Formed Wire Manufacturer

As a reputable formed wire manufacturer, we are very precise when it comes to the selection of the materials for the formed wires. Most of our formed wires are made of 304 stainless steel and 316 stainless steel. These two families of steel are known for their strength, durability, and resistance to corrosion.

Other materials for the formed wires include aluminum, brass copper, carbon steel, among others. As a buyer, you are free to choose your preferred material for the formed wire.

We also follow an intricate manufacturing process for the formed wire. It all starts from the design phase where we create an outline for the product according to the customers’ specifications. This also allows us to create different designs and dimensions for the formed wires. You can also request the customized formed wires. We then implement various manufacturing procedures to have the final product that will be ready for use.

Formed Wires Buyer Guide

After the installation of conductors on transmission lines, the process does not stop there. You will find it necessary to ensure that the conductors are properly attached to their positions. There are different types of support mechanisms that are used for holding conductors or even when joining conductors. One of these mechanisms is formed wires.

Planning to buy formed wires for your transmission line project? It is prudent to ensure that you not only buy the wire but also the right one that will perfectly meet your needs. We are going to look at some of these wires and at the end of it all, you will be able to choose the best-formed wires.

What are Formed Wires?

These are wires that have been manufactured from the wire forming process. This is a process in which wire spools are designed shaped and configured to have certain specifications.

The wire spools can be configured in any shape and form depending on the intended area of application. They are also customized to have different sizes and dimensions. Some are large while others are small. Some formed wires are thick while others are thin. There is also a variation of the lengths for the formed wires.

After the conventional manufacturing process, formed wires undergo further post-manufacturing procedures that are designed to boost their strength and protect them from both physical and chemical damage.

Also, it is important to note that formed wires are made from strong materials. The most common ones include stainless steel, carbon steel, brass, copper, zinc, and other alloys. The choice of the formed wire material will solely depend on your area of application or what you intend to use the wire for.

How are formed wires created?

The final formed wires that we see in the market are products of well-curated plans and procedures. Formed wires manufacturers use special machines that are designed for the mass production of formed wires.

Otherwise, here are the steps that are followed when producing formed wires:

Step 1: Design specification

The requirement specifications for the formed wires are laid down at this stage of production. This is done keeping in mind the application area of the formed wires.

All the dimensions and configurations for the wire are laid down at this stage of production. Issues such as the length and diameter of the formed wires are highlighted at this stage.

Step 2: Selection of the formed wire material

The materials for the formed wires are selected based on their physical and chemical properties. Metals such as aluminum steel, copper, and many others are chosen based on their ability to serve the intended purpose of the formed wire.

Step 3: Manufacturing

Once the material is ready, formed wire is subjected to various manufacturing techniques which include;

-Manual wire forming: It is an old technique that is used for the production of small volumes of formed wires. Hand-operated machines are used for bending and drawing the formed wires.

-Coil wire forming: This method involves winding a wire on a metal blank. The number of coils formed from this process will depend on the specifications of the desired end-product.

-Bend wire forming: This process basically entails bending the wire through different angles so that it acquires certain shapes and configurations. This is done without compromising the integrity of the material at any angle.

-CNC wire bending: Here CNC machines are used for bending the wire to give it desired shapes. CNC machines are programmed and operate with high levels of accuracy. They are also ideal for mass production. They are also versatile in that they can easily bend different materials.

Types of Formed Wires

Formed wires come in different forms. Some are simple products while others have complex designs. Here are some of them;

Distribution tie

A distribution tie is usually considered as an alternative for the armor rods. It has a hand tie wire and encased with an insulator. A distribution tie is usually installed with a pad, especially when used on the naked conductors.

The main function of this formed wire is to offer protection against abrasion due to the constant movement of the conductor. Distribution ties can also replace the hand tie wires.

Guy dead-end

This class of formed wire is used for guying onto the poles. They are usually used with guy strands which are then connected to the poles.

Conductor splice

This is a formed wire that is used for joining two or more conductors so that they end up forming a strong mechanical bond at the points of their union. The joining also forms an electrical termination point such that electric current cannot flow beyond that point. The conductors may be welded or soldered at the spliced to enhance their bond.

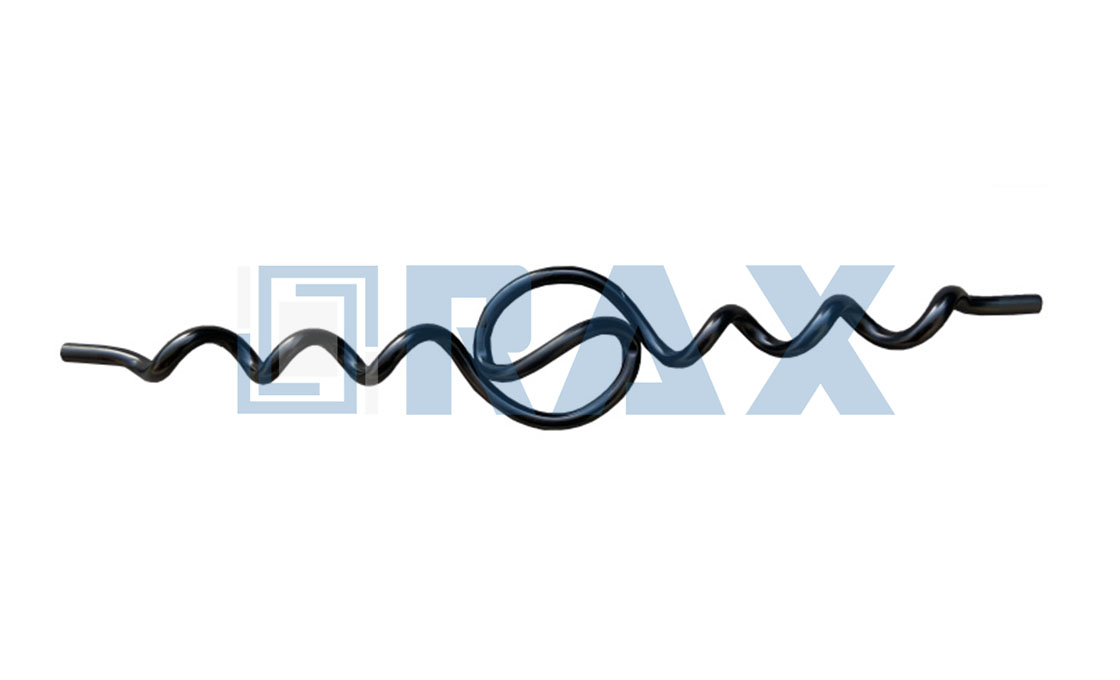

Spiral vibration damper

The primary function of a spiral vibration damper is to minimize vibrations on the conductors. It also reduces the stress that is caused by vibrating conductors. The vibration can be installed in two ways; single installation and double installation.

The damper is designed to be used with different conductors and can handle different power capacities. It is also non-corrosive and can withstand high temperatures.

Line guards

A line guard is a formed wire that is designed to protect a conductor by minimizing the bending. It also minimizes the effects of corrosion and abrasion on the conductor. The level of protection that a line guard provides depends on the various factors including the environmental temperature, and tensional force that is exerted on the conductor.

Suspension clamp

A suspension clamp is a formed wire that is used for clamping conductors along the longitudinal axis. The arms of the suspension clamp extend outwards on the opposite side of the conductor. Sections of the conductor cable are rested on these arms. This means that the cable is free to oscillate within the given arms.

Insulator tie

Also known as a distribution tie, this is a class of formed wire that is used for connecting conductors to the spool insulator. It can also be designed to make a connection to the pole top insulator. These formed wires are made of aluminum though some are made of non-conductors such as PVC.

There are three main types of insulator ties. These are top ties, side ties, and spool ties. Insulator ties usually work with labels, neck tubes, and guy grips.

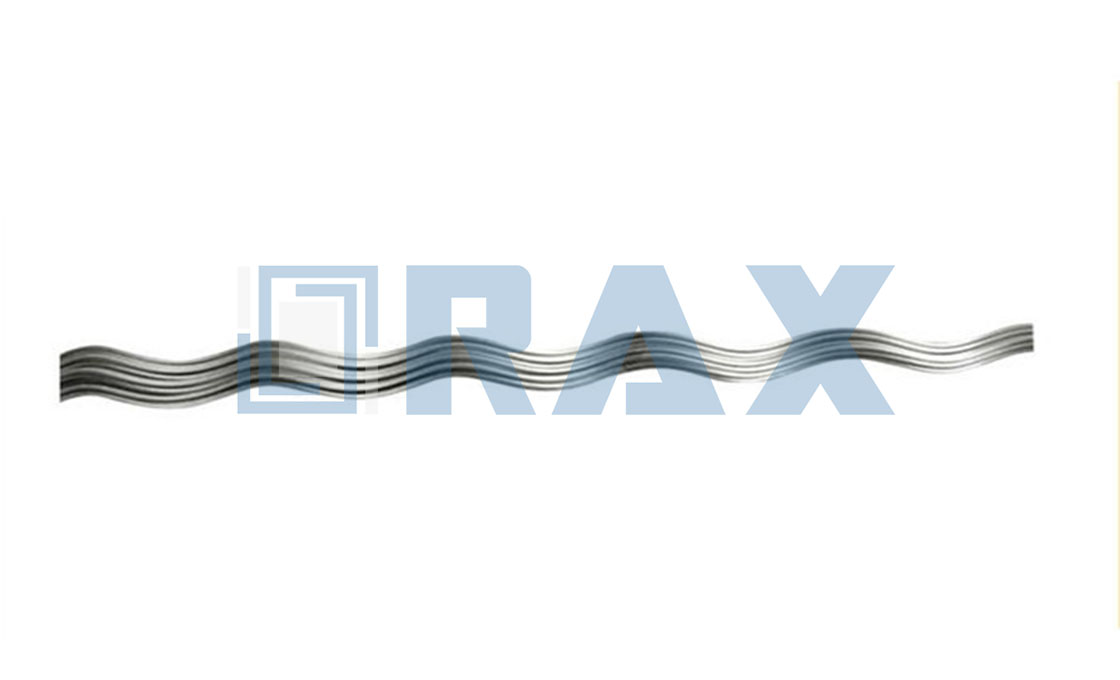

Armor rod

Armor rods play a protective role on the transmission line. They shield the conductor from the effects of bending, abrasion, and compression. As a class of formed wire, armor rods are marked with different color codes and are easy to install.

Grip dead-end

This is a formed wire that is designed to create a tight grip on the conductor. The grip is uniform hence preventing distortion of the conductor due to the external forces. The design of the grip dead-end provides the required holding strength that will support the continuation of conductors. It has a simple design hence easy to install.

Conclusion

Many products can be engineered from formed wires and we have just listed some of them. Also, formed wires have a wide range of applications across different industries. They are also applicable in both small-scale and large-scale installations. Simply contact us for detailed specifications.