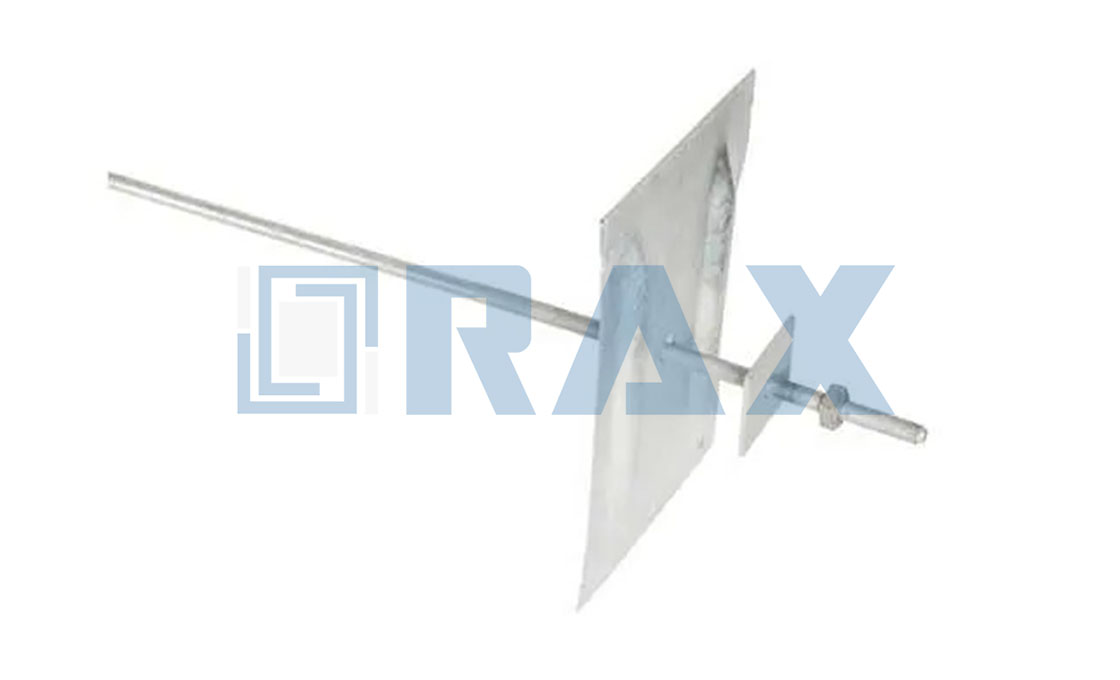

Helical Wall Anchor

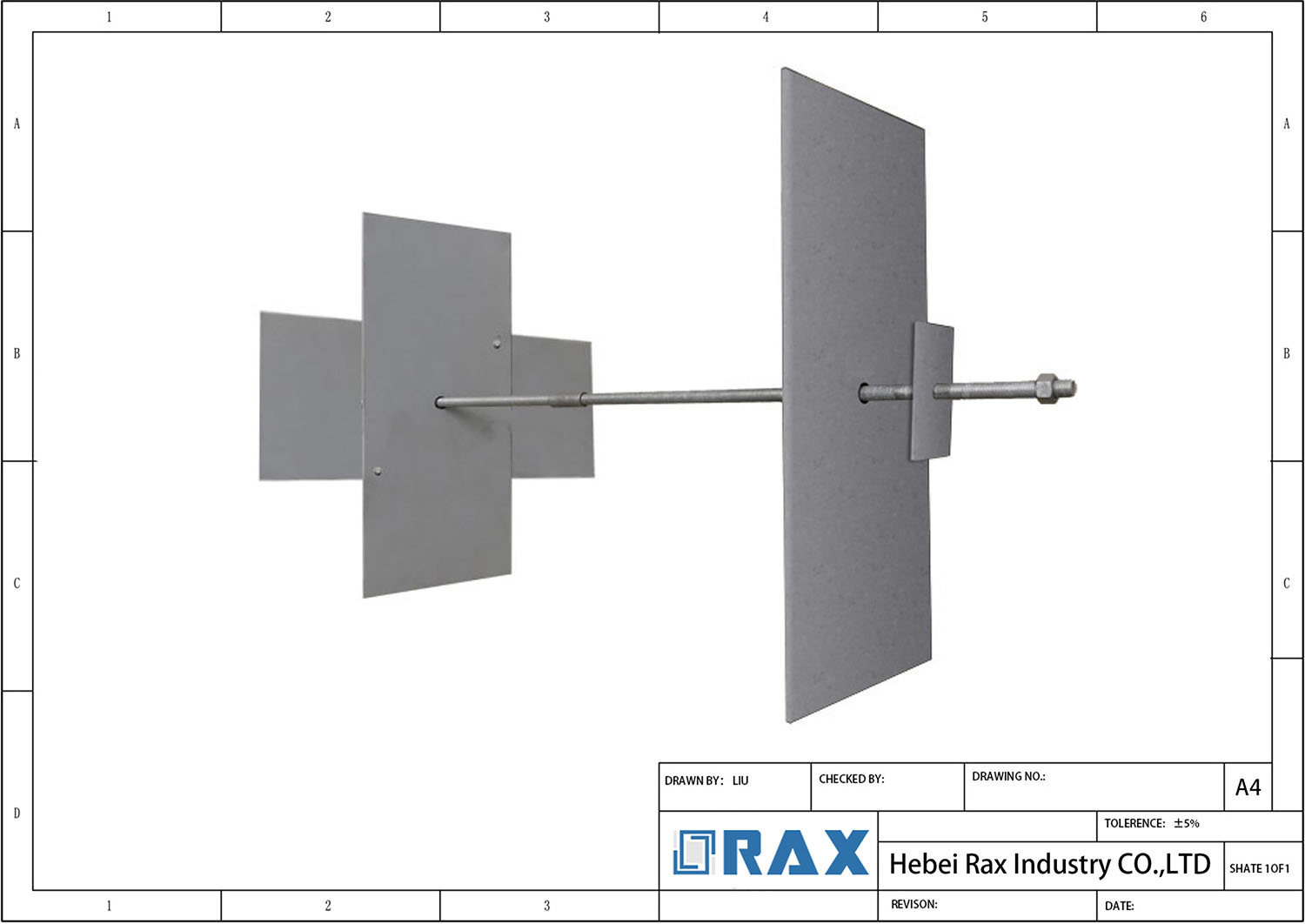

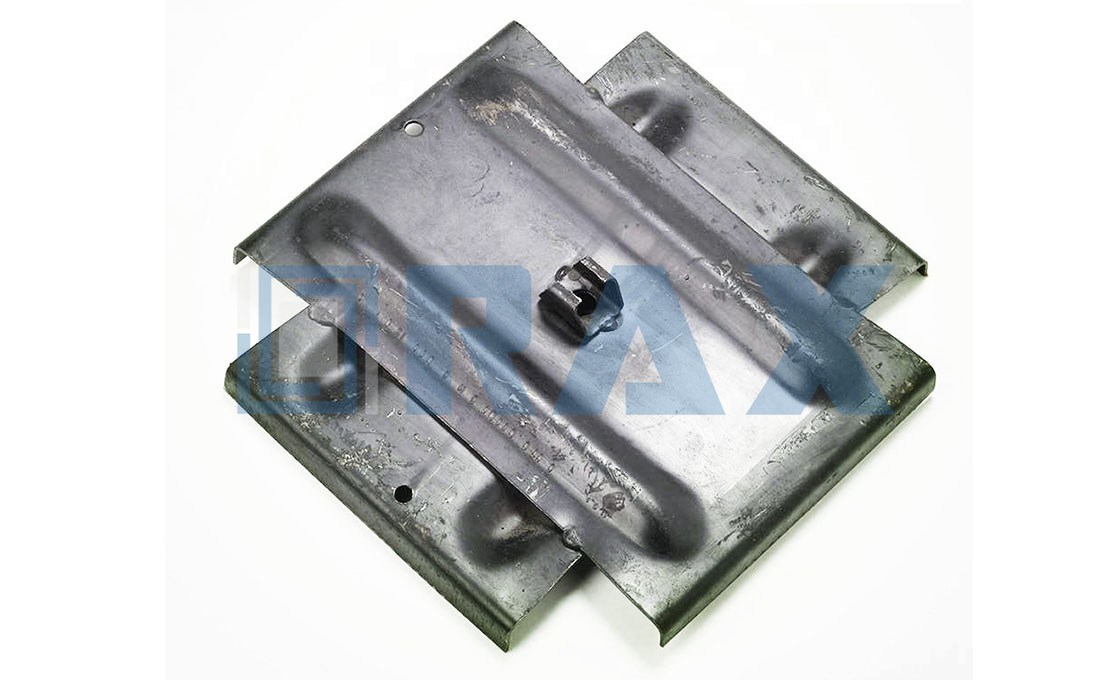

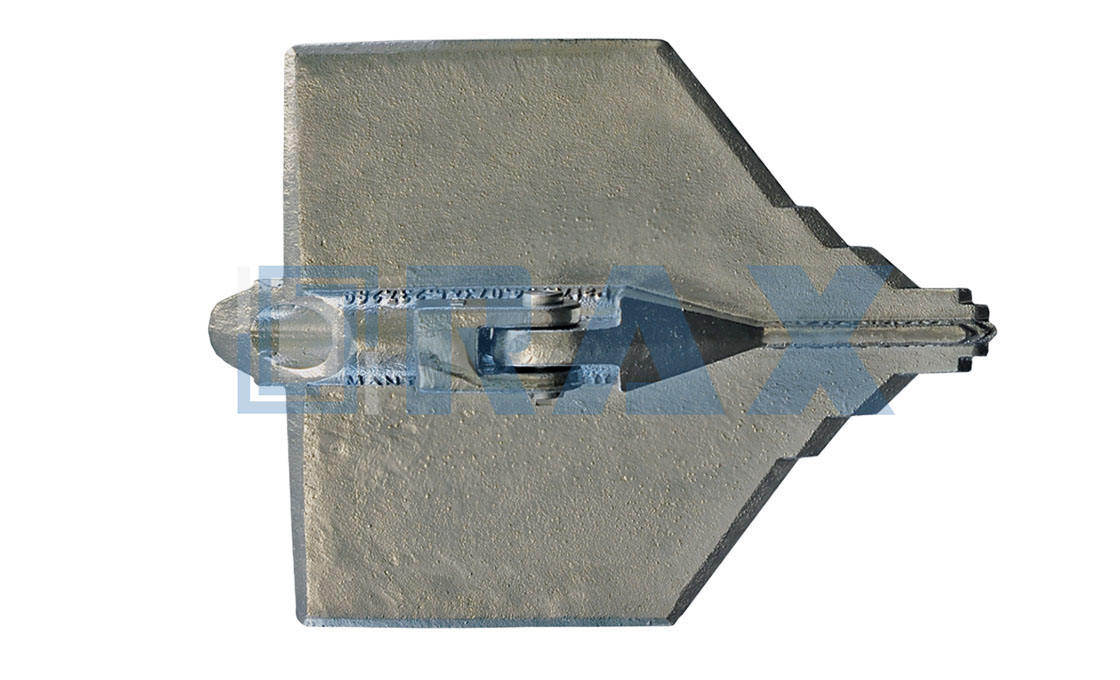

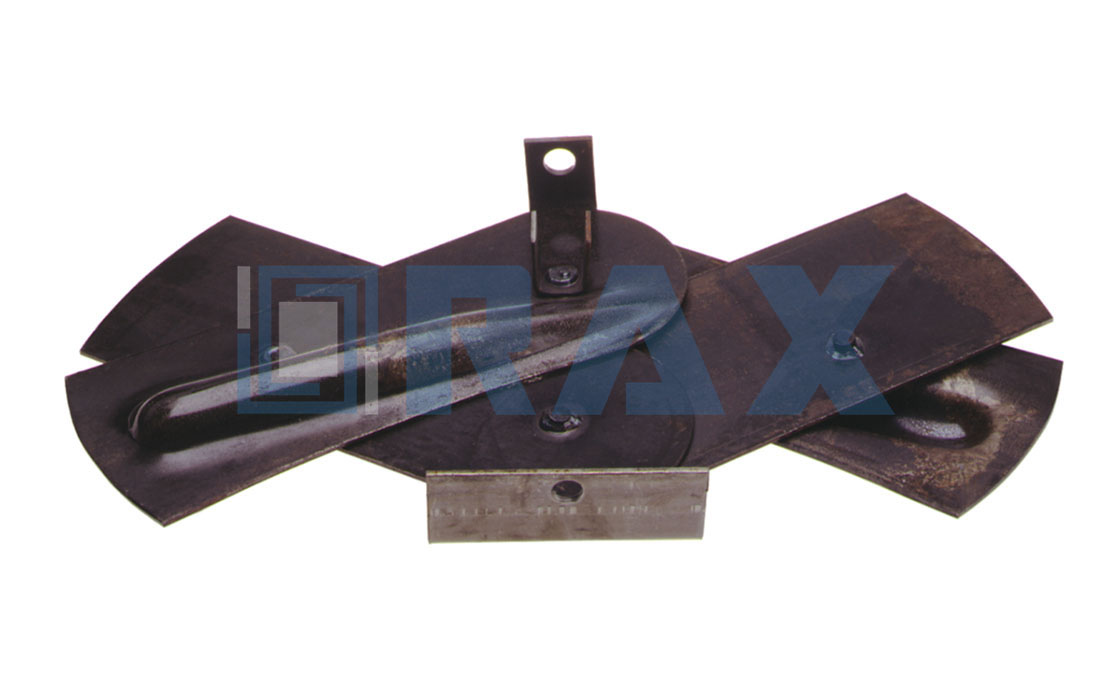

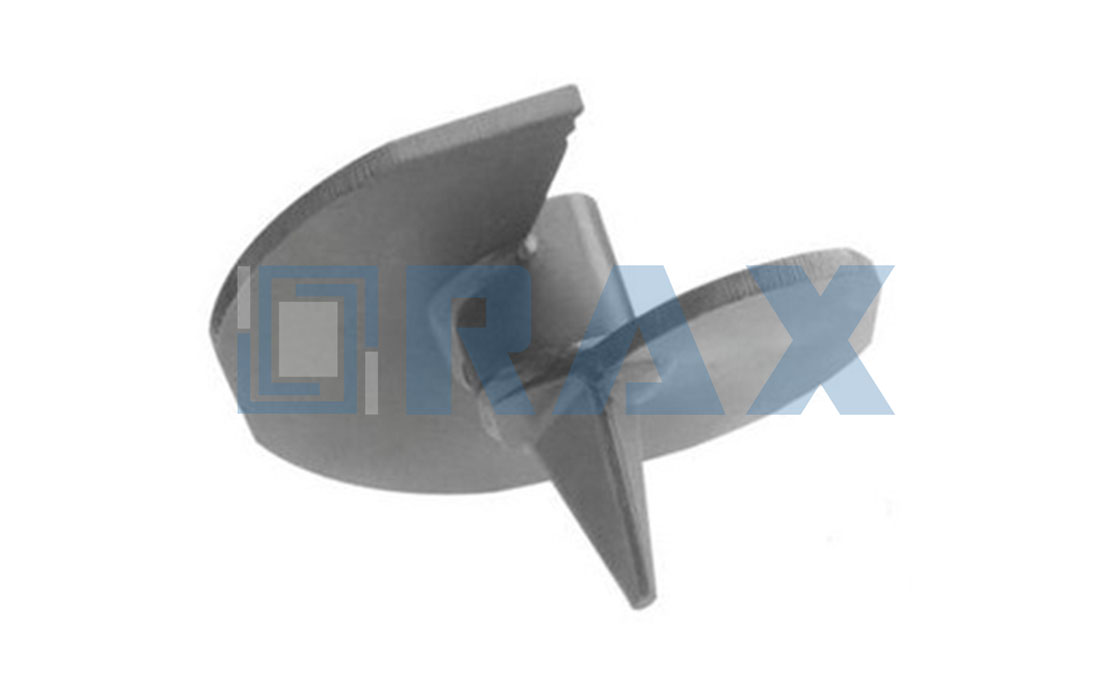

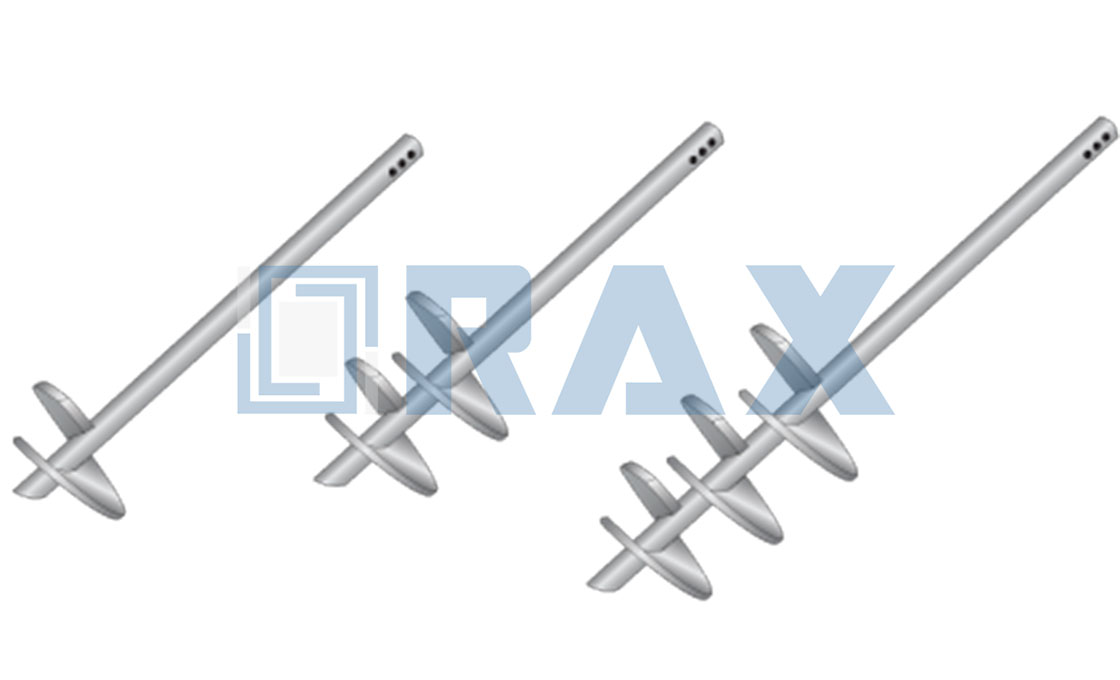

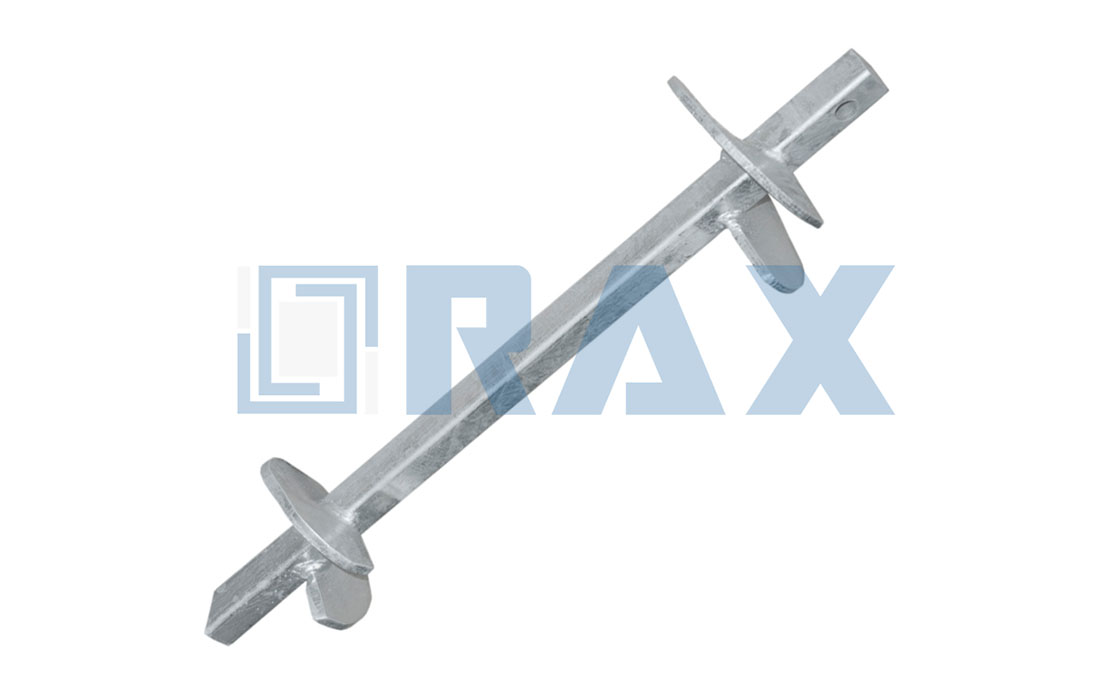

Helical wall anchors, also known as helical tieback anchors, are deep foundation support systems consisting of a central steel shaft with welded helical plates. These anchors are available in various configurations including hollow round shafts for alternating compression and tension loads, or solid square shafts, with plate diameters typically ranging from 8 to 14 inches. The central shaft components come with true helix-shaped plates that maintain a standard 3-inch pitch and are spaced between 2.4 and 3.6 times the helix diameter.

Helical wall anchors function by transferring structural loads directly to stable soil through their helical bearing plates. Installation involves rotating the anchor into the soil using hydraulic torque equipment, with the installation torque directly correlating to the anchor’s load-bearing capacity. They are particularly effective in loose and water-saturated soils, providing immediate load-bearing capacity without waiting for grout or concrete to cure. The system typically includes a load transfer device (bracket) that connects to the structure, allowing for both compression applications where the anchor is driven downward and tension applications where it provides uplift resistance.

Key Features:

- Hot-dip galvanized coating compliant with ASTM A123 for corrosion protection

- Multiple helix configurations with precise spacing for optimal soil engagement

- Direct shaft-to-coupling contact for efficient load transfer

- Installation possible with minimal site disruption and no excavation required

- Immediate load testing capability through torque correlation monitoring

- Engineered coupling systems for both tension and compression applications

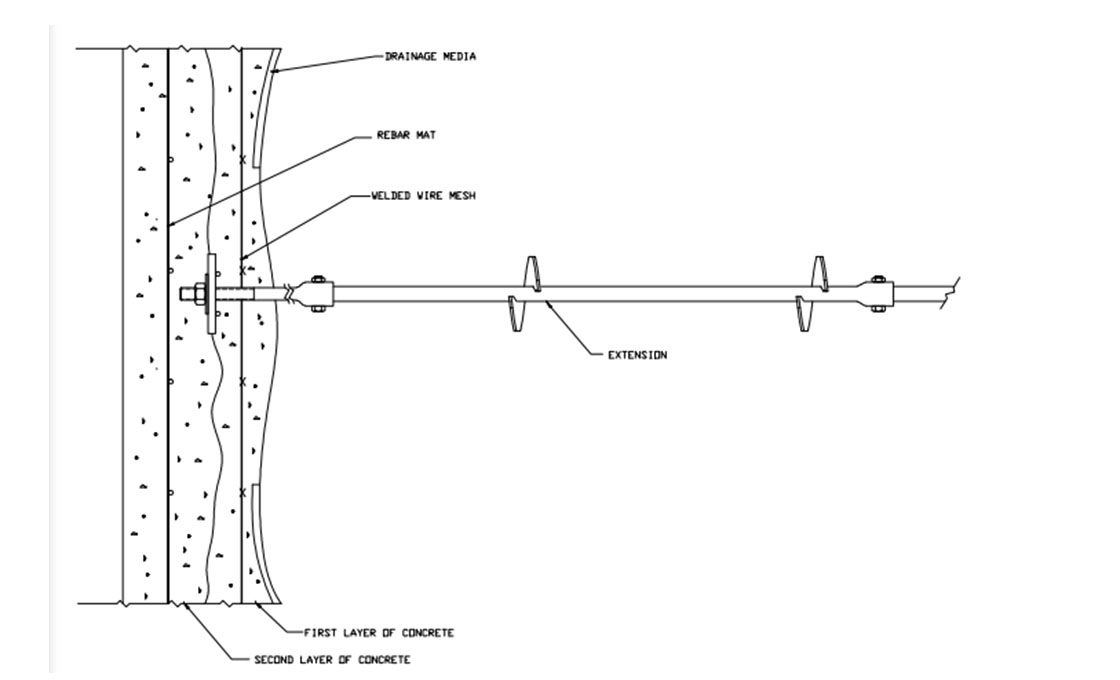

Helical Wall Anchor Drawing

Frequently Asked Questions

What are the exact components of a helical wall anchor system?

What are the exact components of a helical wall anchor system?

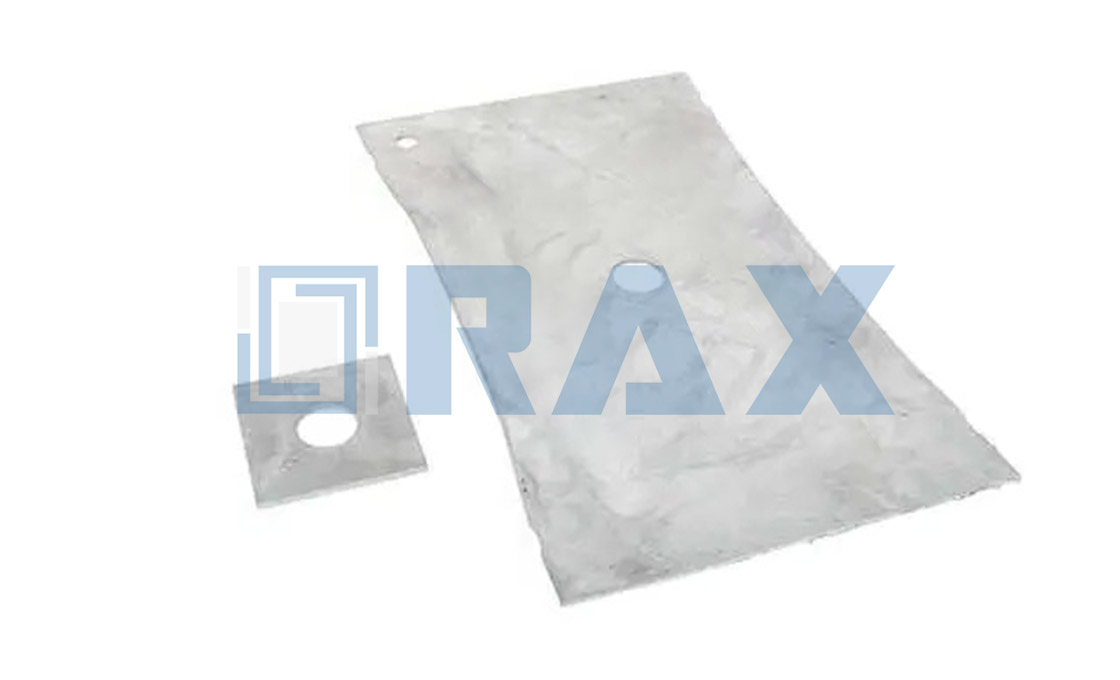

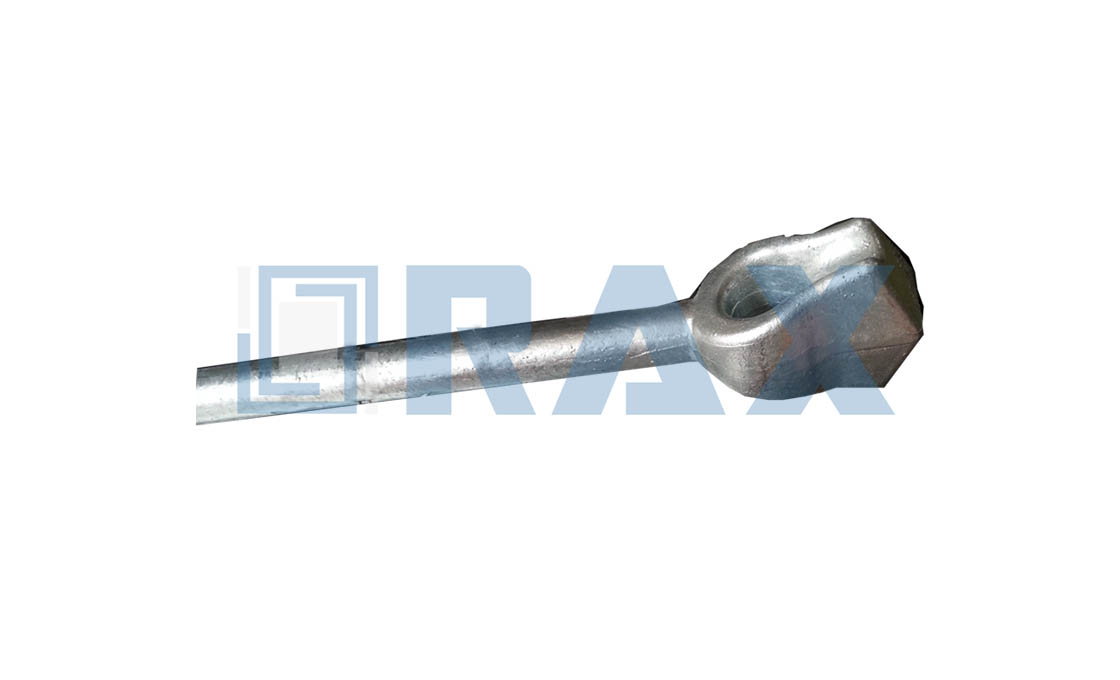

The system consists of three main parts: a lead section with helical plates welded to a central steel shaft, extensions with male/female couplers, and a termination system including a thread bar adapter, steel bearing plate, threaded anchor nut, and wall plate for load distribution.

What are the specific installation spacing requirements?

Installation requires one anchor per 3.5 ft² of wall area, with maximum 32″ horizontal and 25″ vertical spacing. Around openings larger than 16″, additional anchors must be placed within 12″ at maximum 36″ intervals.

What is the installation process?

Installation involves drilling through the foundation wall at a downward angle, rotating the anchor into soil using hydraulic equipment at 8-10 RPM. The process includes torque monitoring and wall plate attachment, typically taking 1-2 hours per anchor.

What soil conditions are suitable?

Effective in clay, sand, loam, and water-saturated soils. Cannot be used in areas with gravel deposits larger than 3 inches, solid rock, or bedrock. Soil must provide consistent torque readings during installation.

What are the load capacity specifications?

Capacities reach up to 200,000 pounds per anchor, determined through torque correlation during installation. The system allows for immediate load testing without curing time, with capacity directly proportional to installation torque.

What causes foundation walls to need anchors?

Foundation problems typically result from soil pressure due to poor drainage, water-logged soil, improper soil compaction during construction, or soil erosion. These factors cause walls to bow or lean inward.

What are the corrosion protection requirements?

All components must receive hot-dip galvanized coating compliant with ASTM A123 standards, ensuring corrosion protection in aggressive soils and providing a 75-100 year service life.

What are the exact components of a helical wall anchor system?

What are the exact components of a helical wall anchor system?