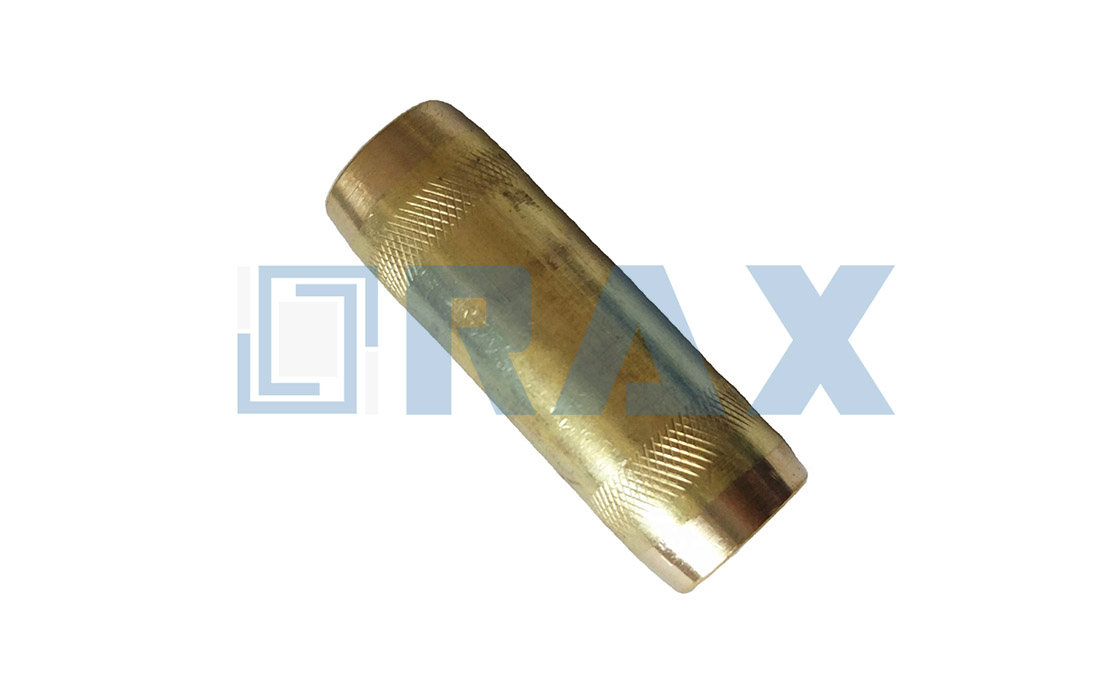

Earth Rod Coupler

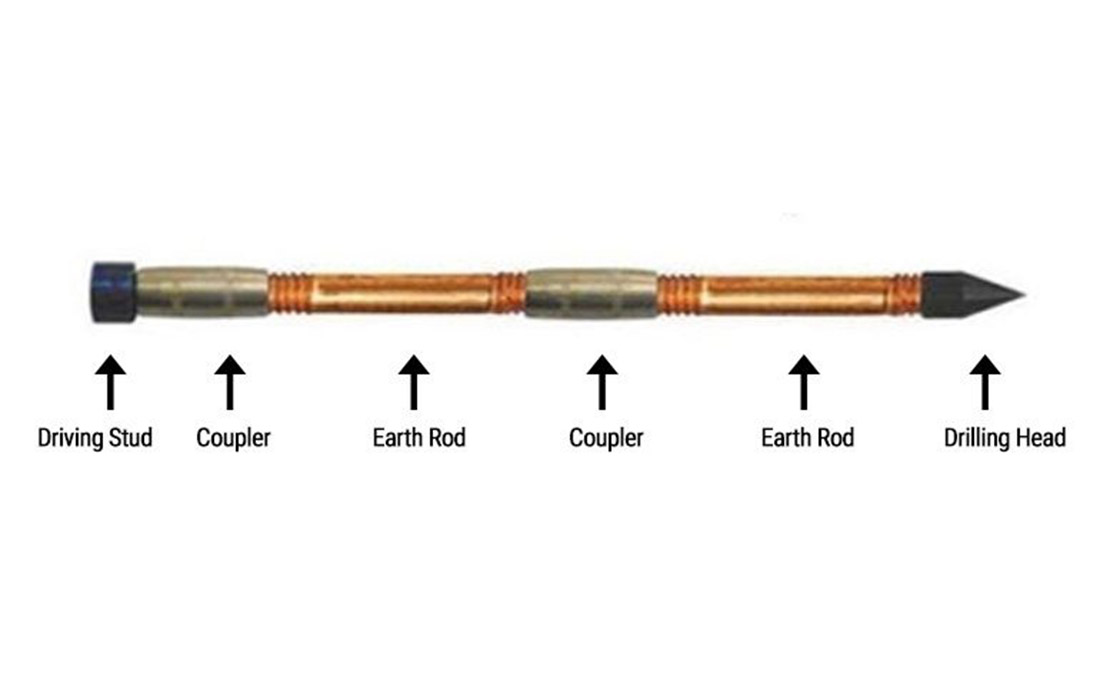

Earth Rod Couplers, also known as threaded couplings, are connecting devices made from high copper content alloy designed to join earth rods together for extended lengths. These couplers consist of a cylindrical body with internal threading that matches the earth rod specifications, available in different sizes to accommodate 5/8-inch and 3/4-inch earth rods. Earth Rod Couplers feature a hole and stud design that creates an automatic secure connection during installation.

The installation of Earth Rod Couplers involves threading them onto the ends of earth rods that need to be joined, ensuring constant contact between the rods both during and after installation. They protect the earth rod threads during the driving process while maintaining permanent electrical conductivity. Earth Rod Couplers work with copper-bonded earth rods, solid copper rods, and threaded earth rods in earthing and lightning protection systems, allowing installers to achieve necessary driving depths in various soil conditions.

Key Features:

• Manufactured from high copper content alloy for excellent corrosion resistance

• Self-closing coupling system for secure mechanical and electrical connections

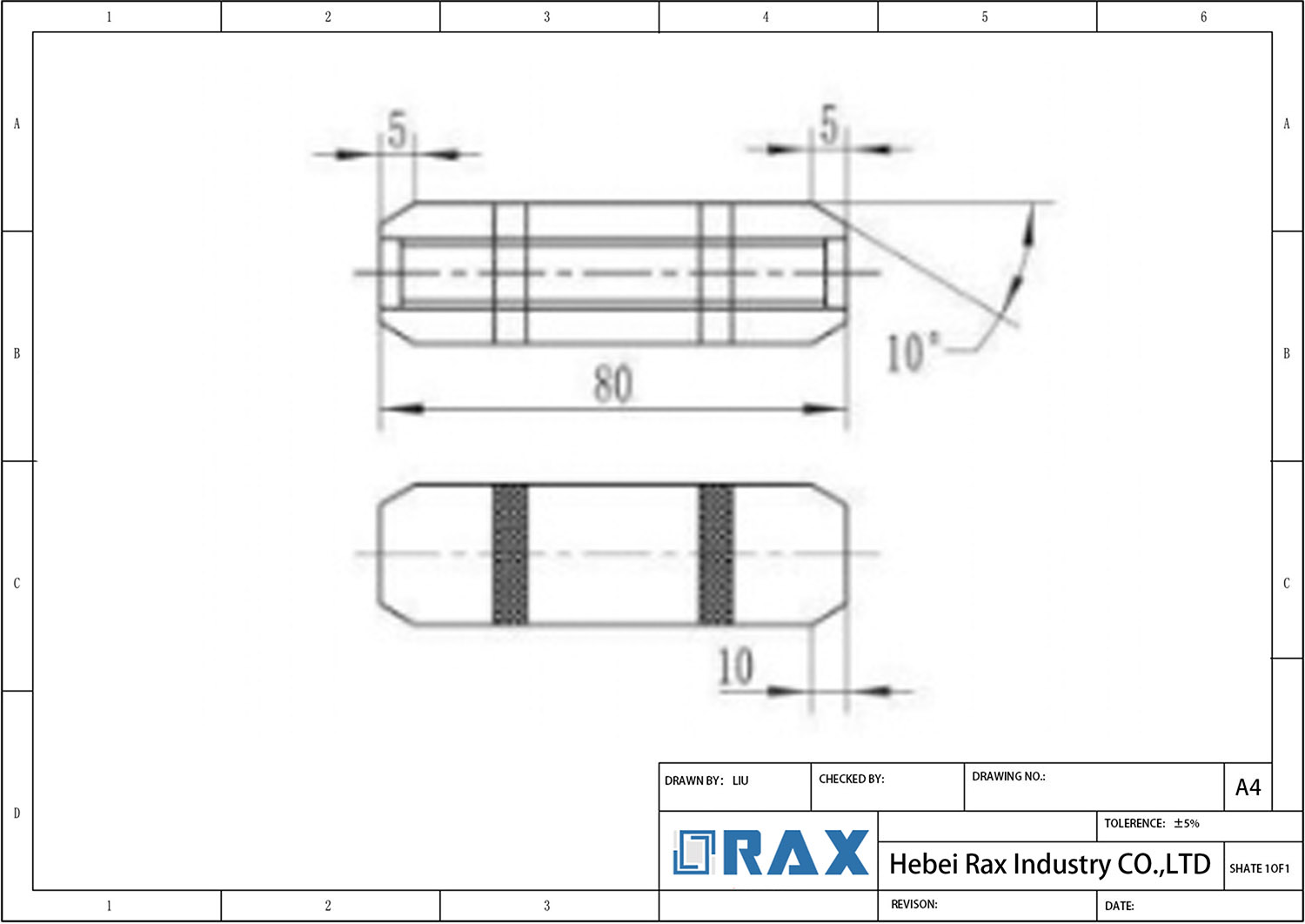

• Available in multiple sizes (68mm x 21mm for 5/8″ rods, 78mm x 25mm for 3/4″ rods)

• Provides permanent electrical conductivity between rod sections

• Protects rod threads during installation process

• Compatible with various earth rod materials and types

Earth Rod Coupler Drawing

| Catalog NO. | Rod diameter (mm) | Screw type (inch) | Material | Weight (kg) |

| ERC9/16 | 12.7 | 9月16日 | Brass/ Galvanized Steel | 0.08 |

| ERC5/8 | 14.2 | 5月8日 | Brass/ Galvanized Steel | 0.1 |

| ERCM18 | 16 | M18 | Brass/ Galvanized Steel | 0.111 |

| ERC3/4 | 17.2 | 3月4日 | Brass/ Galvanized Steel | 0.145 |

| ERCM20 | 18 | M20 | Brass/ Galvanized Steel | 0.147 |

| ERCM22 | 20 | M22 | Brass/ Galvanized Steel | 0.15 |

Frequently Asked Questions (FAQ)

How deep should a ground rod be installed?

How deep should a ground rod be installed?

A ground rod should be driven into the ground to a depth of at least 8 feet (2.45 meters). This depth ensures effective grounding and compliance with electrical codes. In some cases, deeper installation may be necessary depending on soil conditions and local regulations.

How far apart should multiple ground rods be placed?

Multiple ground rods should be spaced at least 6 feet (1.83 meters) apart. This spacing helps to maximize the effectiveness of the grounding system by reducing interference between rods and ensuring proper dissipation of electrical current into the earth.

What material are earth rod couplers made from?

Earth rod couplers are typically made from high copper content alloy. This material ensures excellent corrosion resistance and high strength, making it ideal for long-term use in various soil conditions. The copper alloy also provides good electrical conductivity for effective grounding.

How do you connect earth rods using couplers?

To connect earth rods using couplers, drive the first rod into the ground, leaving the top thread exposed. Tighten the coupler onto the exposed thread, leaving half of the coupler free. Screw the second rod into the remaining threads and tighten to 30 Nm. Repeat for additional rod extensions.

What is the purpose of earth rod couplers?

Earth rod couplers are used to join multiple earth rods together, allowing for deeper penetration into the ground. They ensure constant electrical contact between rods during and after installation, protect rod threads from damage, and help achieve the necessary depth for effective grounding in various soil conditions.

Can rebar be used as a grounding rod?

While rebar can be used as a grounding rod, it is not recommended due to its higher susceptibility to corrosion compared to purpose-made ground rods. Rebar may not provide the same level of long-term effectiveness and reliability as copper-clad or stainless steel ground rods.

How do you select the right size earth rod coupler?

Select an earth rod coupler based on the diameter and threading of your ground rods. Common sizes include 1/2″, 5/8″, and 3/4″ diameters. Ensure the coupler is compatible with your rod’s material and has the correct thread pitch for a secure connection.

What is the recommended torque for tightening earth rod couplers?

The recommended torque for tightening earth rod couplers is typically around 30 Nm (Newton-meters). This ensures a secure connection between the rods without damaging the threads or the coupler itself. Always refer to the manufacturer’s specifications for precise torque requirements.

How do earth rod couplers affect the overall resistance of the grounding system?

Earth rod couplers, when properly installed, have minimal impact on the overall resistance of the grounding system. They are designed to maintain consistent electrical conductivity between connected rods. The primary factors affecting resistance are soil conditions, rod depth, and the number of rods used.

Are earth rod couplers suitable for all soil types?

Earth rod couplers are generally suitable for use in most soil types. However, in highly corrosive soils, it’s important to choose couplers made from corrosion-resistant materials like high-copper content alloys. In some cases, additional protective measures or specialized couplers may be necessary for extreme soil conditions.

How deep should a ground rod be installed?

How deep should a ground rod be installed?