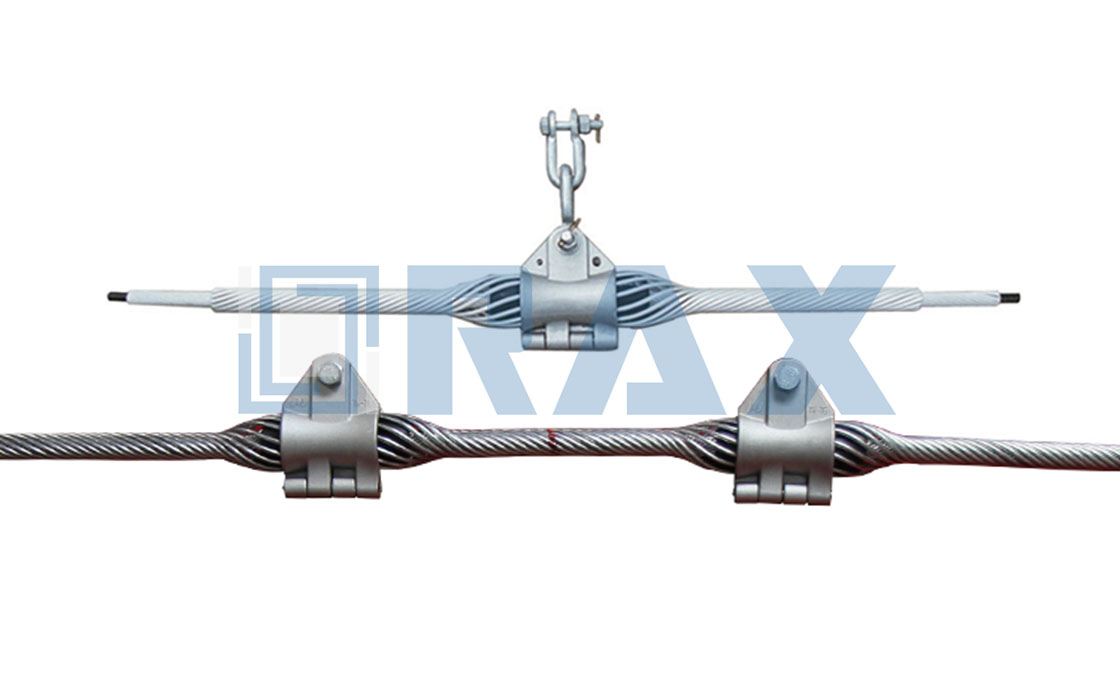

Hot Line Stirrup

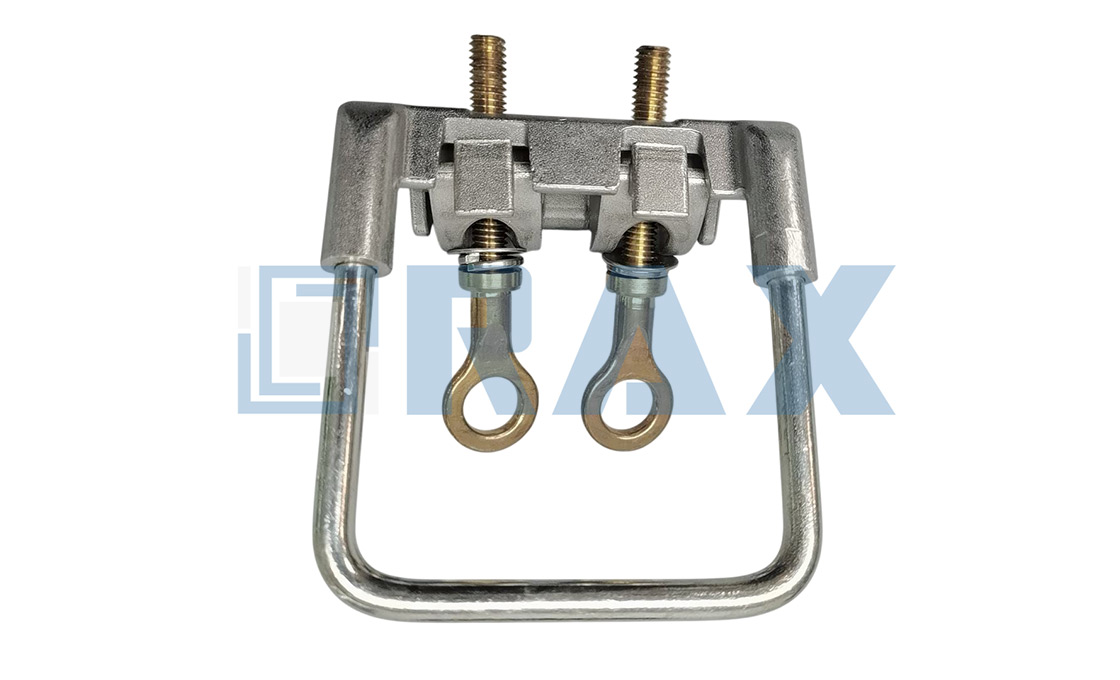

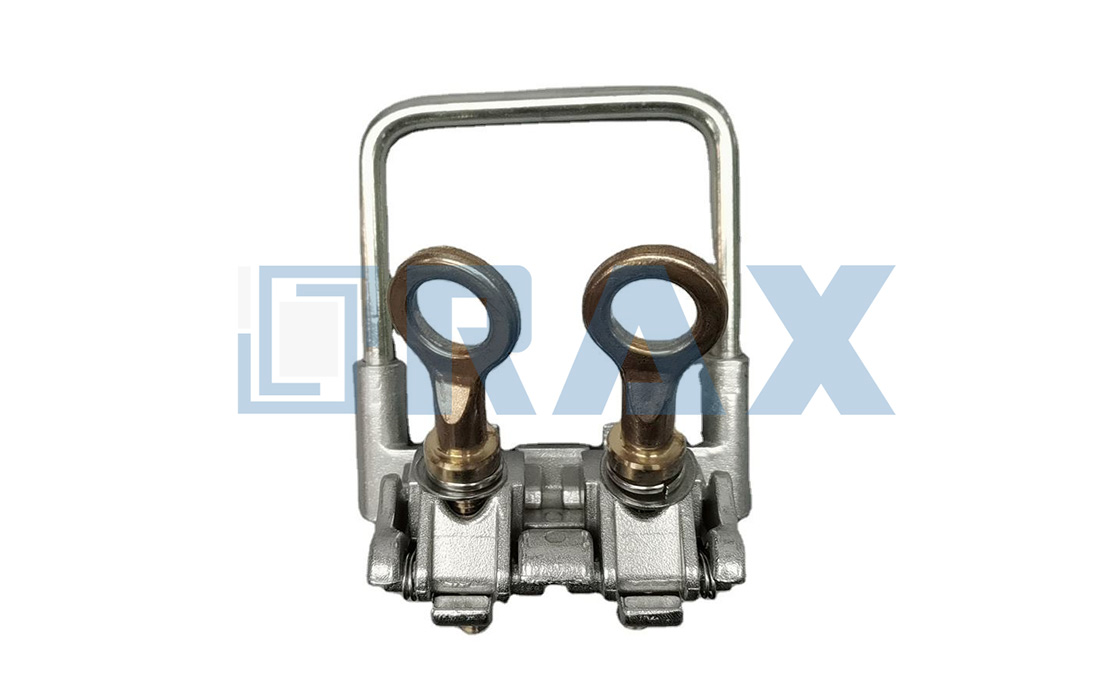

Hot Line Stirrup is an essential electrical connector designed for overhead power line maintenance and protection. The device features a clamp body with aluminum alloy jaws and a copper bail for superior conductivity. These stirrups protect conductors from arcing damage when line clamps are attached or disconnected. They work seamlessly with shotgun-type hot sticks, allowing safe installation on energized conductors without service interruption.

The Hot Line Stirrup incorporates a sophisticated compression joint system with a twin current path design for optimal performance. The device comes in various sizes to accommodate different conductor types, including ACSR and AAC configurations. Its construction features a robust aluminum alloy body with forged steel eyebolts, positioned at a 30-degree angle from the stirrup. The wide stance design ensures exceptional stability during hot line clamp installations.

Key Features:

• Compression joint with oxide-inhibiting compound for enhanced connectivity

• Quick snap-on action mechanism for efficient installation

• Twin current path design for maximum electrical conductivity

• Captured hardware system preventing component separation

• Wide stance construction for superior operational stability

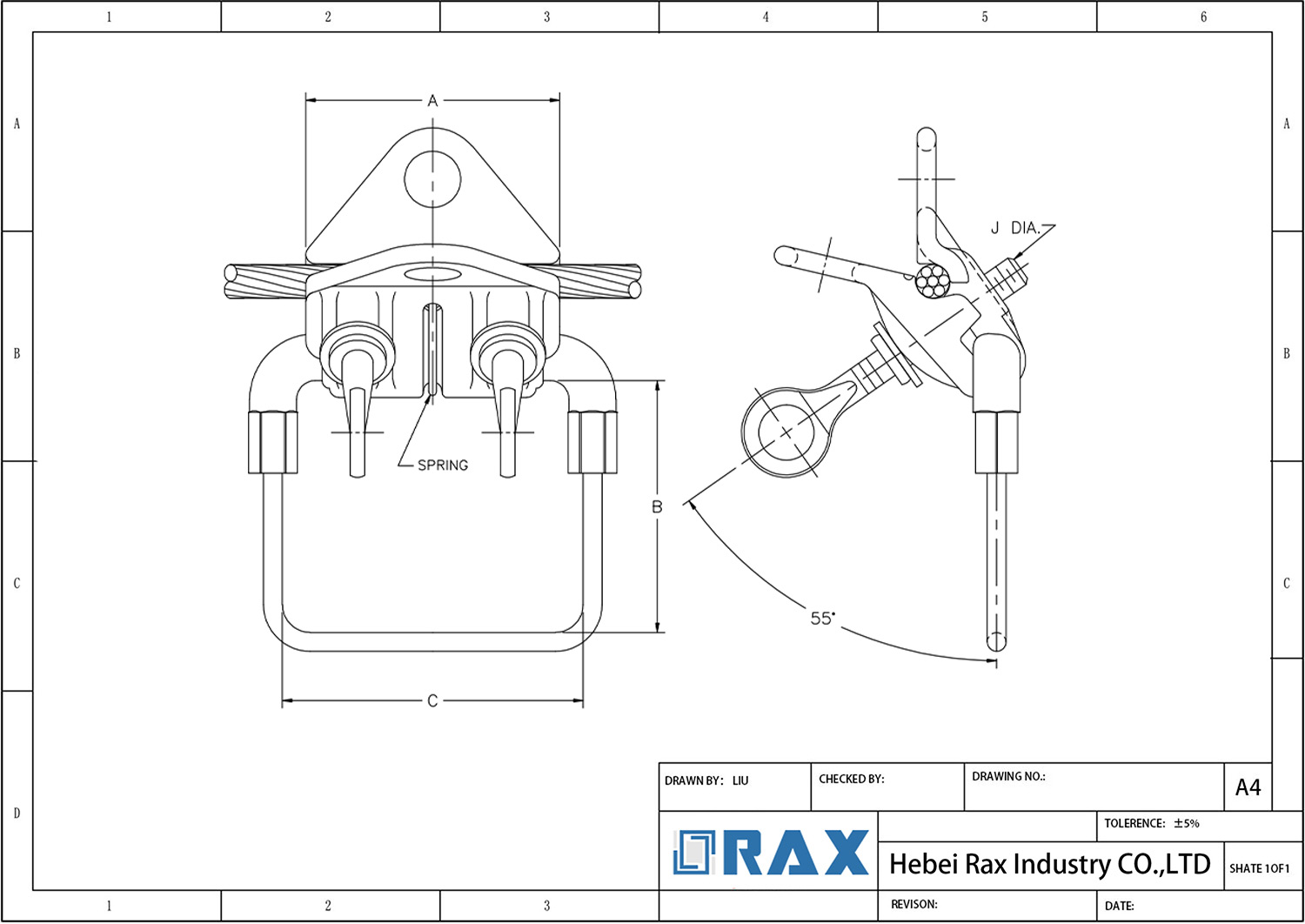

Hot Line Stirrup Drawing

Frequently Asked Questions (FAQ)

What are the main components of a Hot Line Stirrup?

What are the main components of a Hot Line Stirrup?

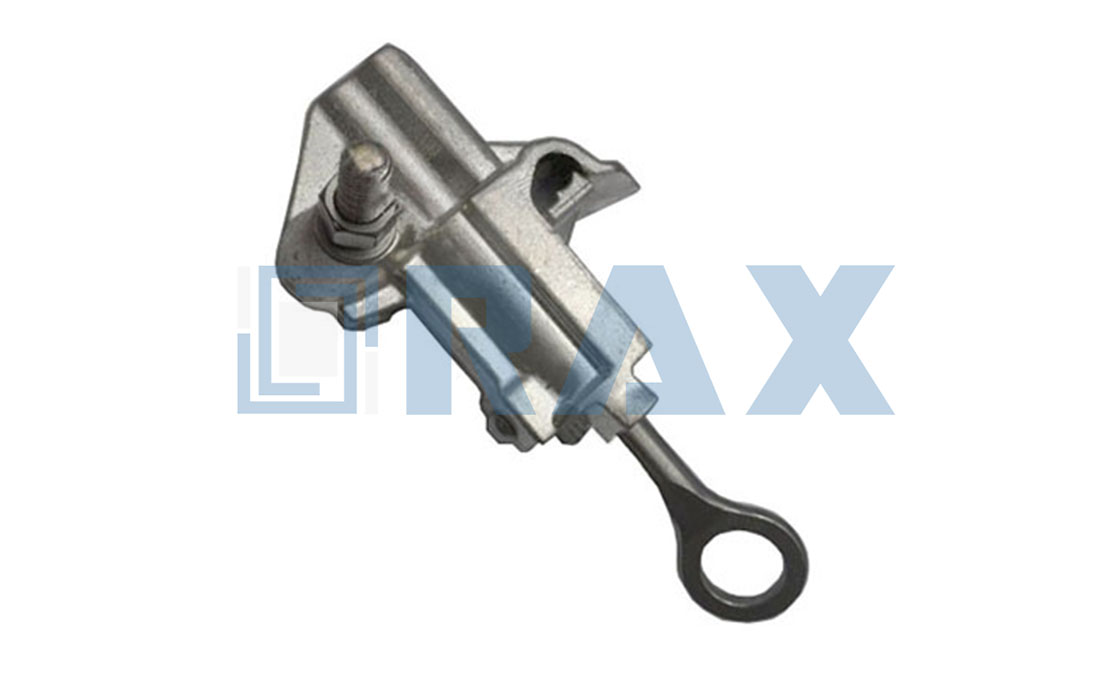

A hot line stirrup consists of aluminum alloy castings for the body, copper rod (typically tin-plated) for the stirrup bail, bronze alloy or stainless steel eye stems, and stainless steel springs. All components are designed to work together for secure electrical connections.

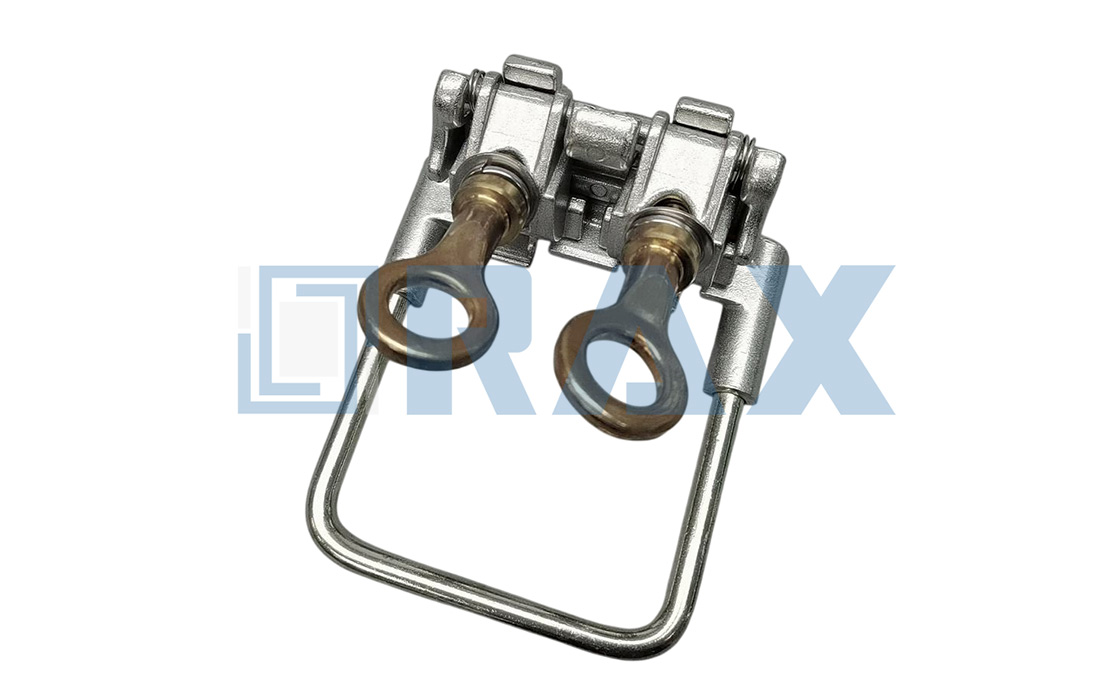

How does the spring mechanism work in Hot Line Stirrups?

The two-bolt stirrup design incorporates clip-type springs that apply moderate pressure on the jaws when pushed onto the line. This pressure is sufficient to support the assembly’s weight while securing the eye stems during installation.

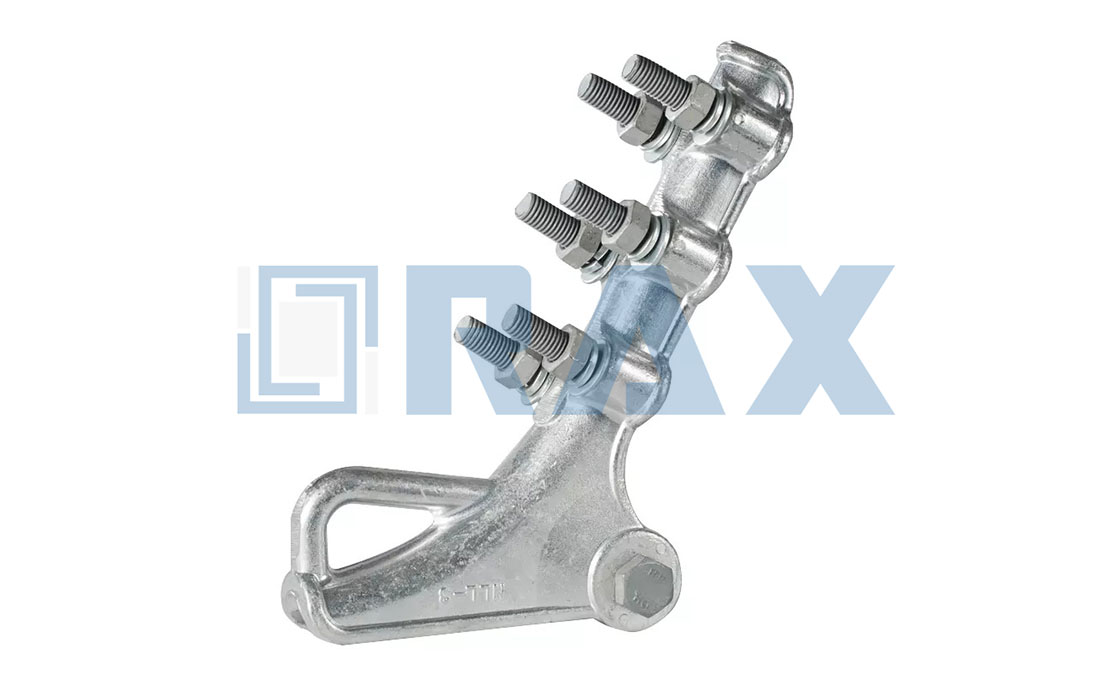

What is the purpose of the angular design in Hot Line Stirrups?

The angular relationship between the stirrup and tightening bolts is specifically engineered for easy installation approach, allowing the stirrup to hang straight down during the installation process.

What are the key features of Hot Line Stirrups?

Hot line stirrups come with compression joint inhibitor filling, snap-on action capability, twin current path design, captured hardware to prevent disassembly, inhibitor-filled conductor grooves, and individual polyethylene packaging.

How is a Hot Line Stirrup installed?

Installation requires cleaning the main conductor with a conductor brush, mounting the eye stem onto a universal grip all tool (shotgun stick), hooking the stirrup onto the main conductor, and tightening to the recommended torque specifications.

What is the recommended torque for Hot Line Stirrups?

The maximum installation torque for hot line stirrups is 200 inch-pounds. Proper torque ensures secure connection while preventing damage to the components.

What are the main components of a Hot Line Stirrup?

What are the main components of a Hot Line Stirrup?