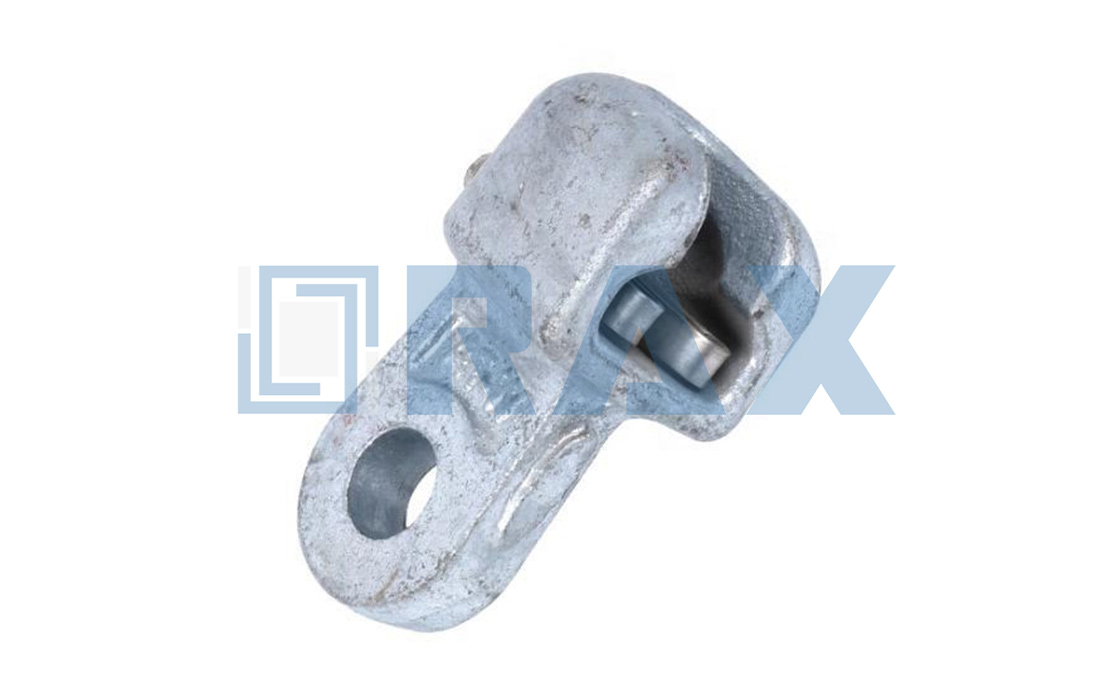

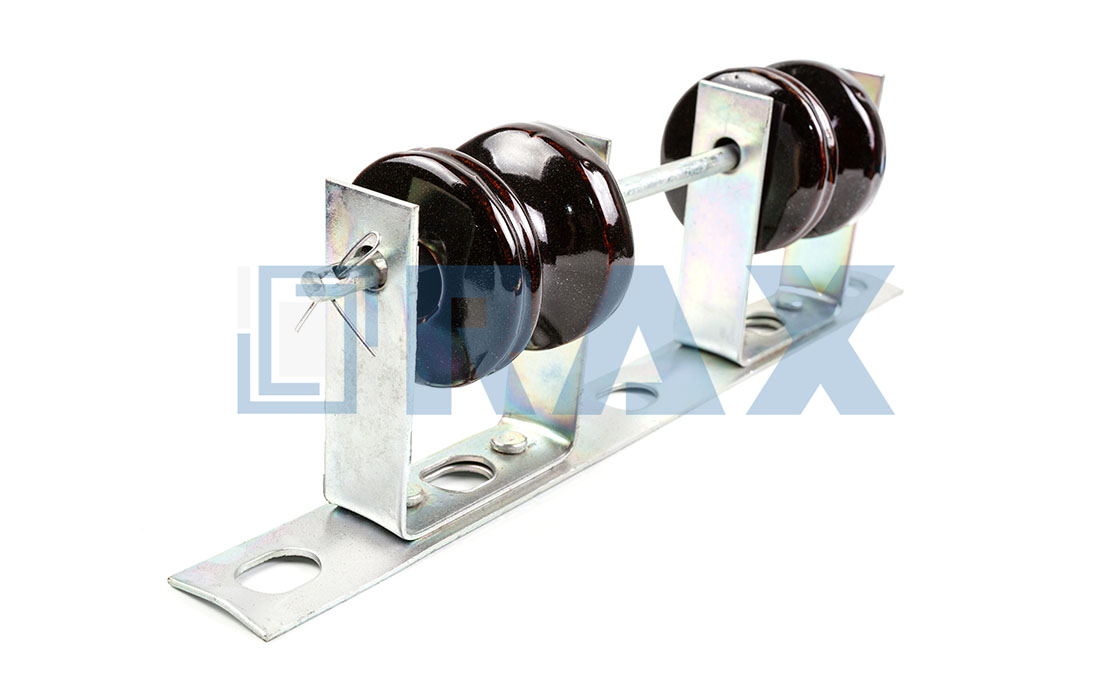

Socket Eye

A Socket Eye is a specialized connecting device designed to link conductor clamping devices with ball-and-socket insulators. They serve as crucial intermediary components in electrical power systems. Socket Eyes create secure attachment points between conductors and insulators, maintaining reliable electrical connections.

These essential hardware components feature a rounded socket end that accepts ball-type fittings. Socket Eyes come in various sizes to accommodate different conductor and insulator specifications. The design incorporates robust materials to withstand environmental stresses and electrical loads. When properly installed, they ensure stable mechanical support while facilitating electrical current flow through the system.

Socket Eyes require proper torque application during installation to prevent loosening. The installation process involves inserting the ball end of the insulator into the socket cavity. Multiple Socket Eyes can be used in series or parallel configurations depending on system requirements. Regular inspection helps maintain optimal performance and identify any wear or damage.

Features:

• Precision-engineered socket cavity for secure ball-type connections

• Heavy-duty construction for maximum mechanical strength

• Weather-resistant finish to prevent corrosion

• Compatible with standard ball-and-socket type insulators

• Available in multiple size configurations for various load requirements

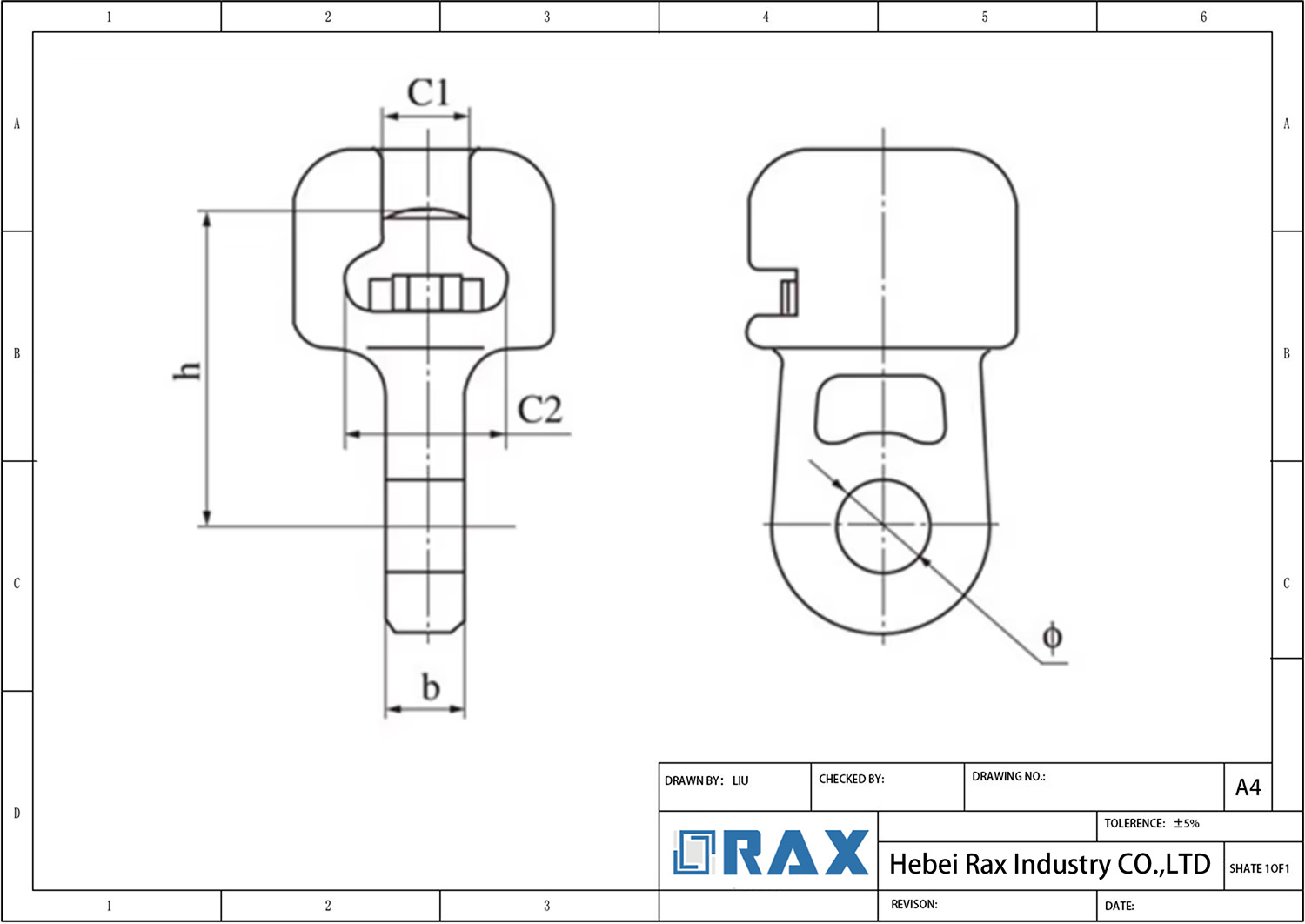

Socket Eye Drawing

| Catalog No. | Dimensions (mm) | Designated size of coupling |

Rated Failing

load(kN) |

Weight (kg) |

||||

| b | Ci | C2 | h | Ø | ||||

| W-7A | 16 | 19.2 | 34.5 | 70 | 20 | 16 | 70 | 0.80 |

| W-7B | 16 | 19.2 | 34.5 | 115 | 20 | 16 | 70 | 0.92 |

| W1-10 | 18 | 19.2 | 34.5 | 85 | 20 | 16 | 100 | 0.90 |

| W1-12 | 20 | 19.2 | 34.5 | 90 | 24 | 16 | 120 | 1.30 |

| W-12 | 20 | 23 | 42.5 | 90 | 24 | 20 | 120 | 1.40 |

| W-30 | 32 | 27.5 | 51.0 | 110 | 39 | 24 | 300 | 3.50 |

Frequently Asked Questions (FAQ)

What is a Socket Eye?

Socket eye is a crucial fitting component for insulator chains, manufactured from forging quality medium carbon steel and hot dip galvanized according to industry standards. It’s designed to connect with ball-type insulators.

What are the typical breaking load capacities of Socket Eyes?

Socket eyes come in various load capacities ranging from 40 KN to 120 KN, depending on the application. Standard models typically handle 70-100 KN for medium voltage transmission lines.

What materials are used in Socket Eye construction?

Socket eyes are made from forged steel and undergo hot dip galvanization. The hardware components are galvanized steel, while any included cotter pins are typically made of stainless steel.

How is Socket Eye sizing determined?

Socket eye dimensions are determined by the ball diameter they need to accommodate. Common sizes are designed for 16mm ball eyes, with specifications matched to ensure proper mechanical strength.

What are the main applications of Socket Eyes?

Socket eyes are primarily used in overhead power line distribution systems, specifically in insulator string assemblies. They provide crucial mechanical connections for transmission line hardware.

What maintenance do Socket Eyes require?

Regular inspection for galvanization integrity and mechanical wear is essential. The connection points should be checked periodically for proper alignment and secure fitting with the ball eye component.

What standards govern Socket Eye manufacturing?

Socket eyes must comply with specific industry standards like BS-729 for galvanization and relevant electrical transmission hardware specifications to ensure safety and reliability.

How are Socket Eyes installed?

Installation requires proper alignment with the ball eye component and secure fastening with appropriate hardware. The socket must be properly oriented to ensure maximum mechanical strength and proper load distribution.