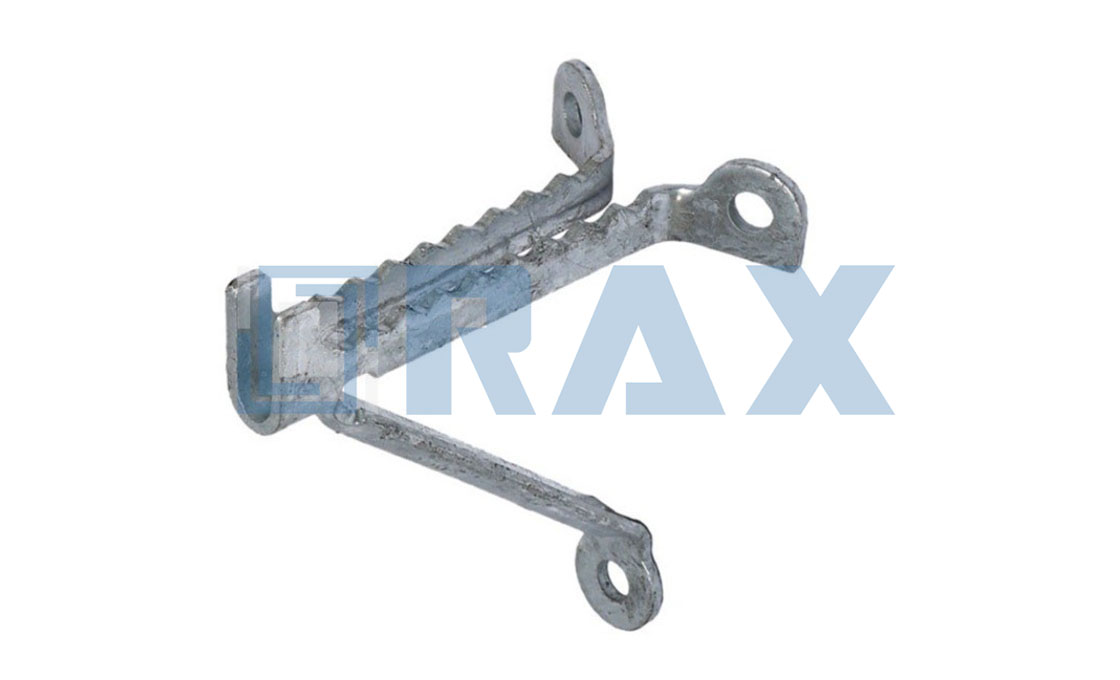

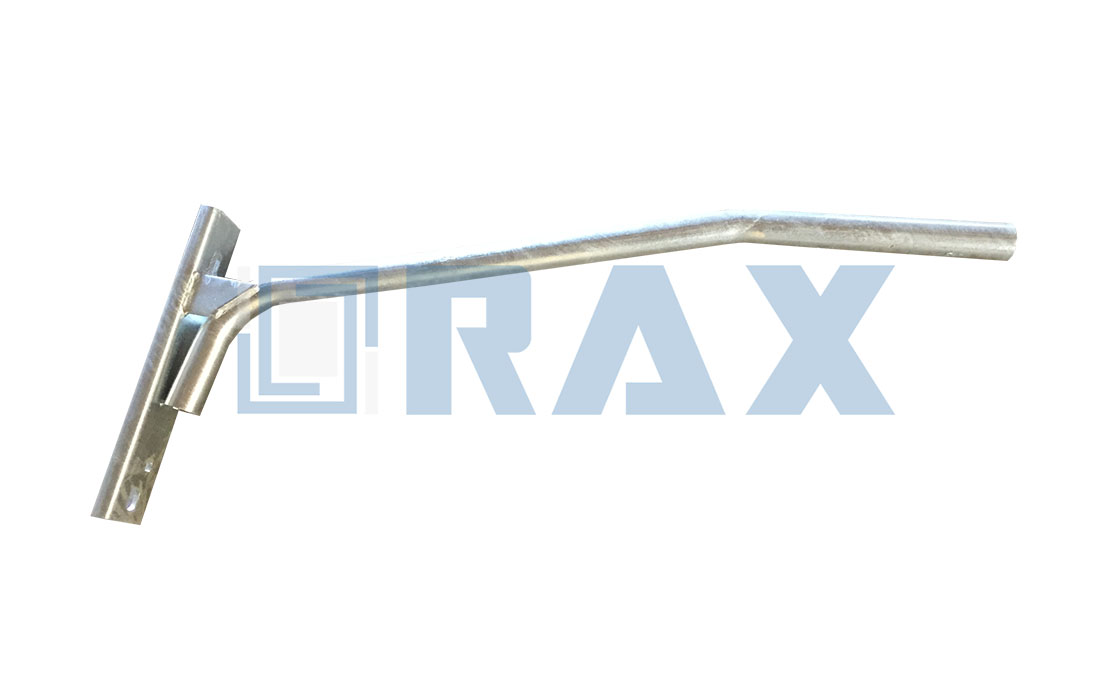

Lift Plate

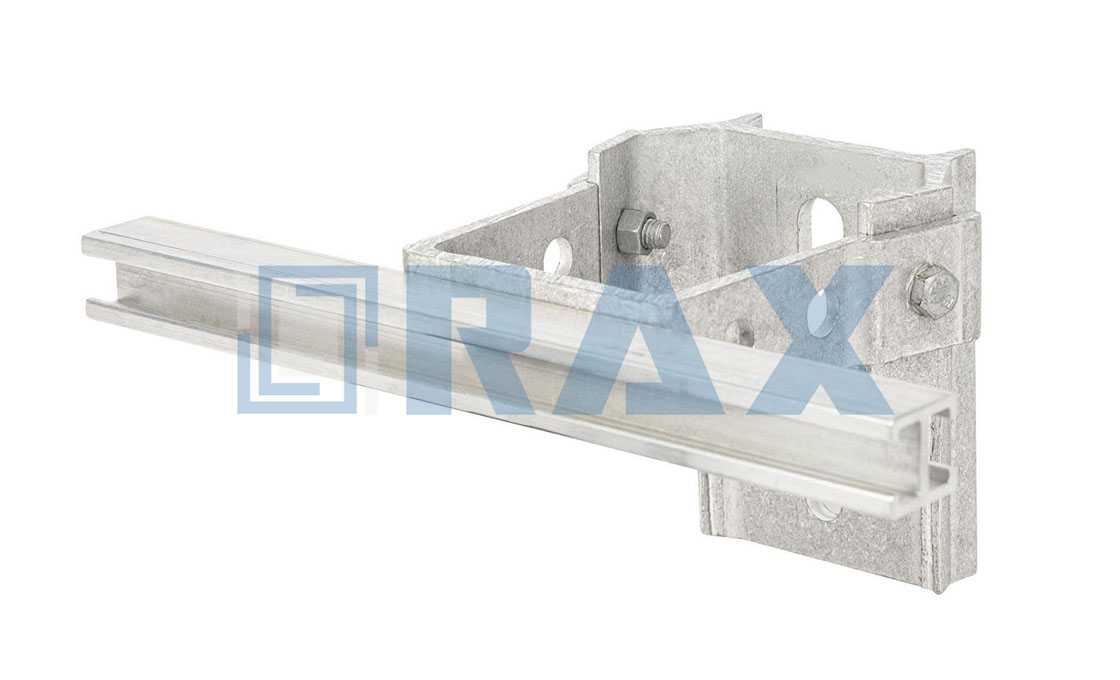

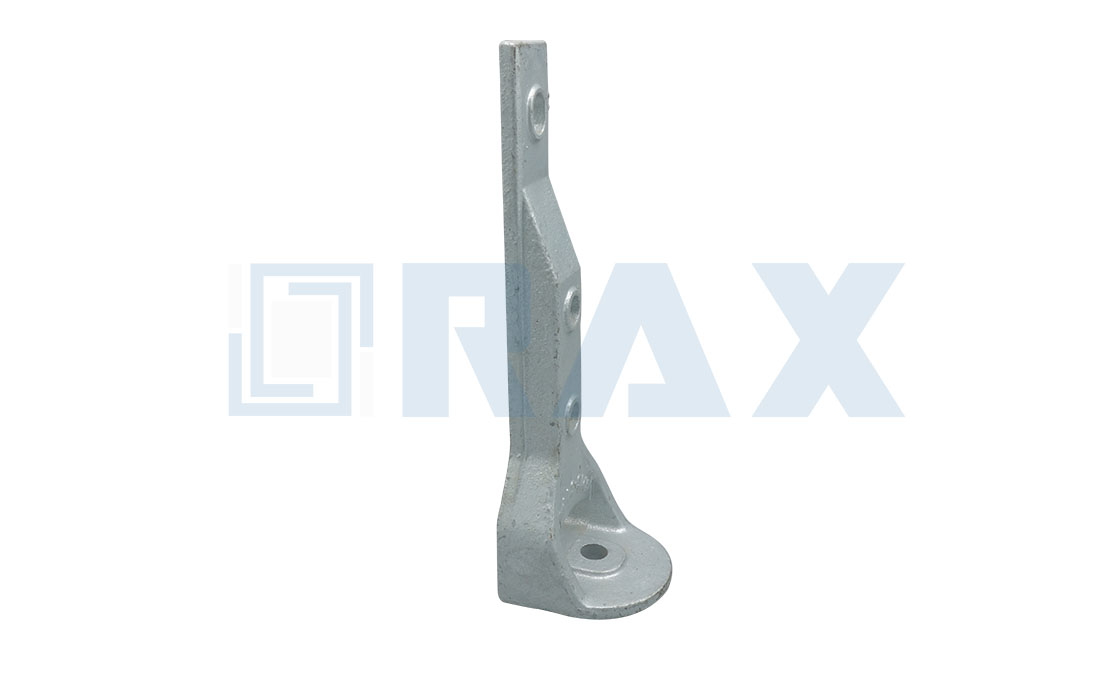

Lift Plates, also called Lift and Load Plates, protect poles during heavy down guying operations with Thimbleye, Angle-Thimbleye, or Oval-Eye bolts. They are specifically designed to increase load capacity when used behind angled guy bolt eyes, particularly in situations with excessive loads or steep guy angles.

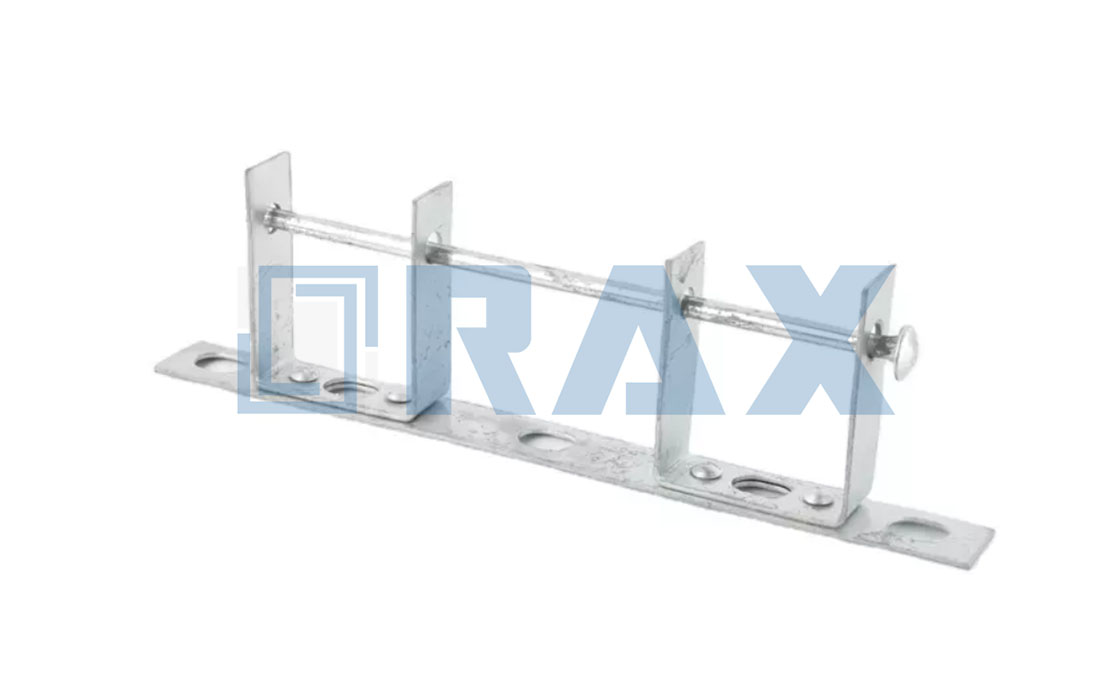

These protective plates come in two primary variants: 2-hole and 3-hole configurations, providing versatile mounting options for different pole applications. Lift and Load Plates create a robust bearing surface that prevents damage to wood pole fibers during wrap-type guying installations. When mounting, 2-4 plates are typically required per pole, depending on the pole diameter.

Features:

• Constructed of high-quality steel with hot-dip galvanized finish for corrosion resistance

• Available with multiple mounting hole configurations for secure attachment

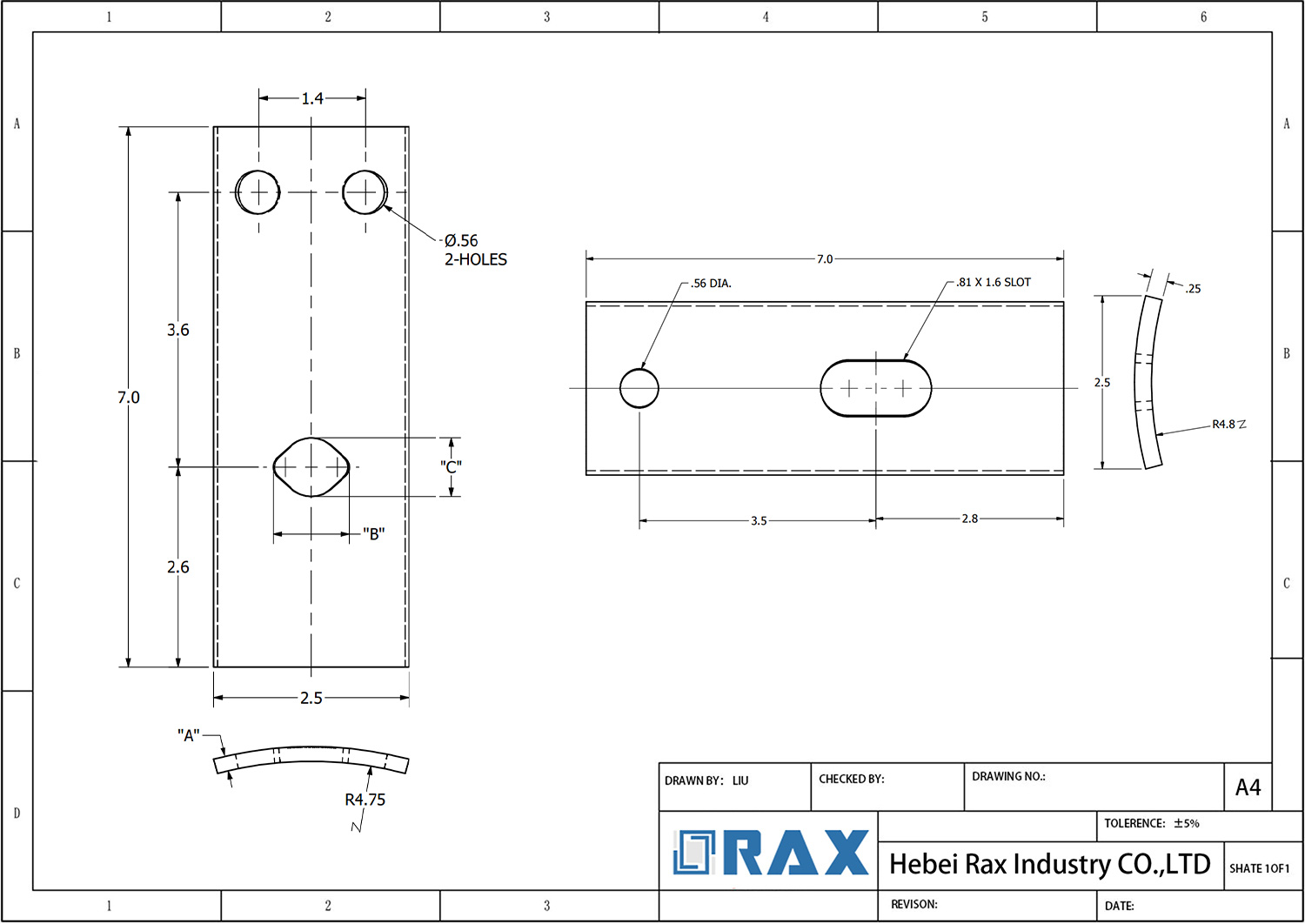

• Curved design with 5-inch radius for optimal pole contact

• Four 3/16-inch nail holes for additional stability

• Compatible with guy hooks for wrap-type guying applications

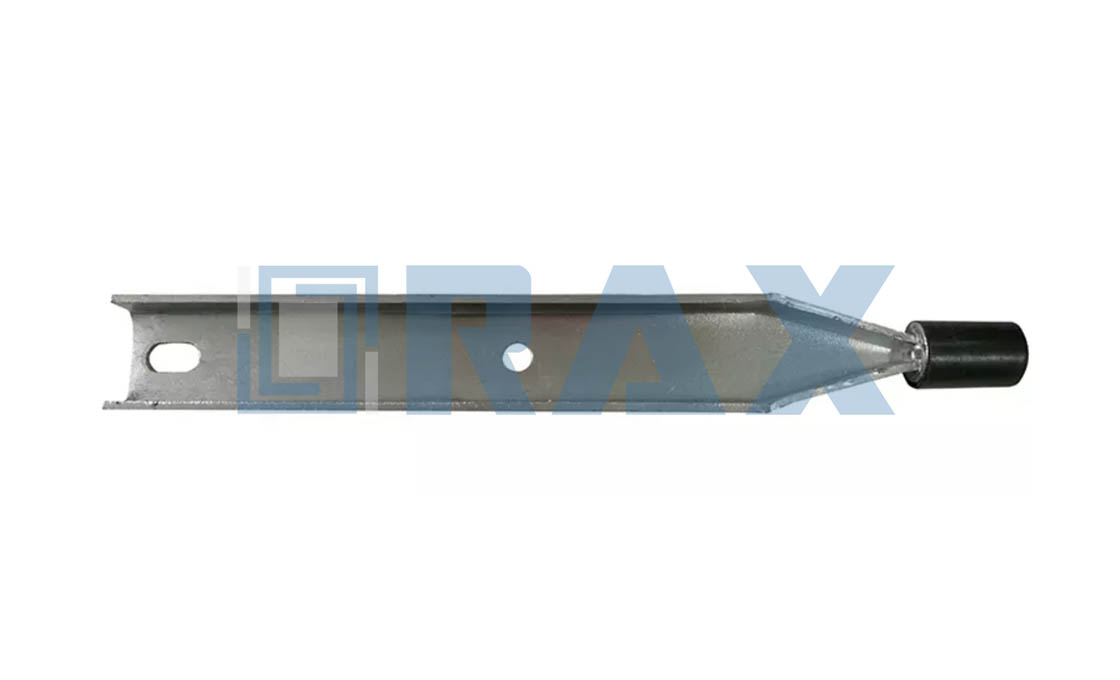

Lift Plate Drawing

Frequently Asked Questions (FAQ)

What is the purpose of a Lift Plate?

Lift Plates are used with Lag Screws behind Angled Guy Bolt eyes to increase load capacity on heavy down guying. They protect poles by distributing weight over a greater surface area, preventing damage to the wood fibers of the pole.

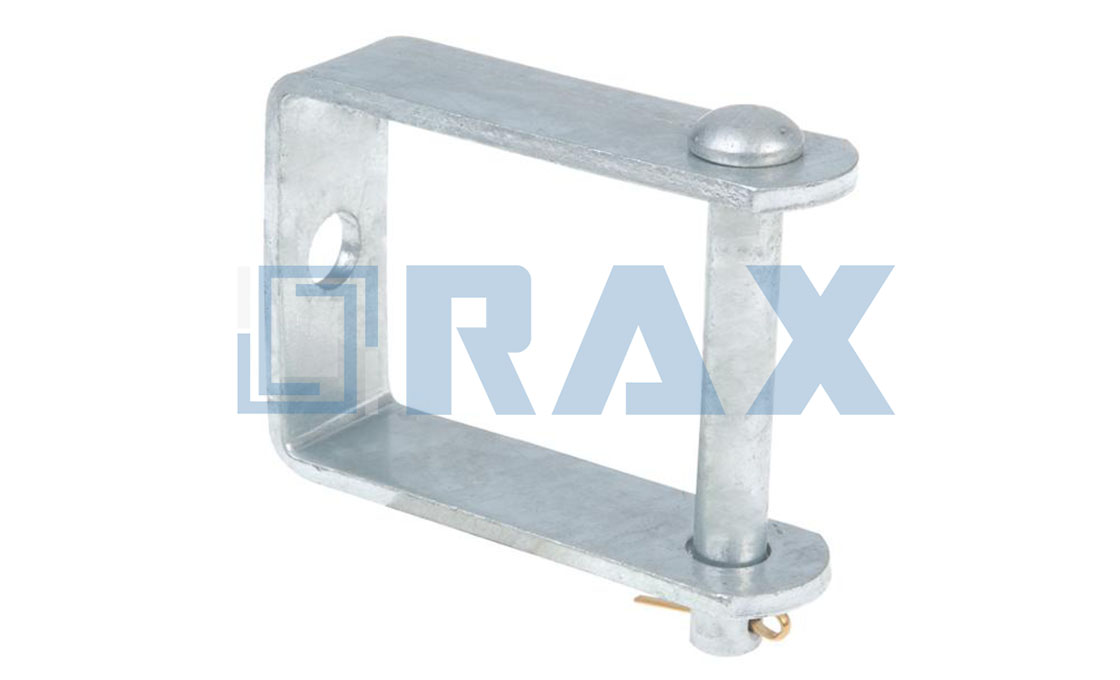

What are the standard dimensions of a Lift Plate?

Standard Lift Plates measure 2-1/2″ x 7″ and are curved on a 4-1/2″ radius. They are constructed of high-quality steel and hot-dip galvanized for durability.

More sizes can be customized

How many Lift Plates are needed per pole?

Depending on the pole diameter, 2-4 plates are required per pole for proper weight distribution and support.

How are Lift Plates attached to the pole?

Lift Plates are constructed with four 3/16″ nail holes for secure attachment to the pole. They can be installed behind guy bolt eyes for increased load capacity.

What type of material are Lift Plates made from?

Lift Plates are manufactured from high-quality steel and undergo hot-dip galvanization treatment to ensure durability and corrosion resistance.