Helical Pulldown Micropile

The Helical Pulldown Micropile (HPDM) is an innovative foundation solution designed to construct a grout column around the shaft of a standard helical pile. This micropile system is also known as Helicast, and it integrates a central steel shaft with helical plates that provide both end-bearing and skin friction. The HPM is particularly effective in weak soil conditions, offering a robust foundation option that can support loads ranging from 20,000 lbs. to over 400,000 lbs. per pile. The installation process involves screwing the helical shaft into the ground while simultaneously injecting flowable grout into the cylindrical void created around the shaft, ensuring a strong bond and enhanced load capacity.

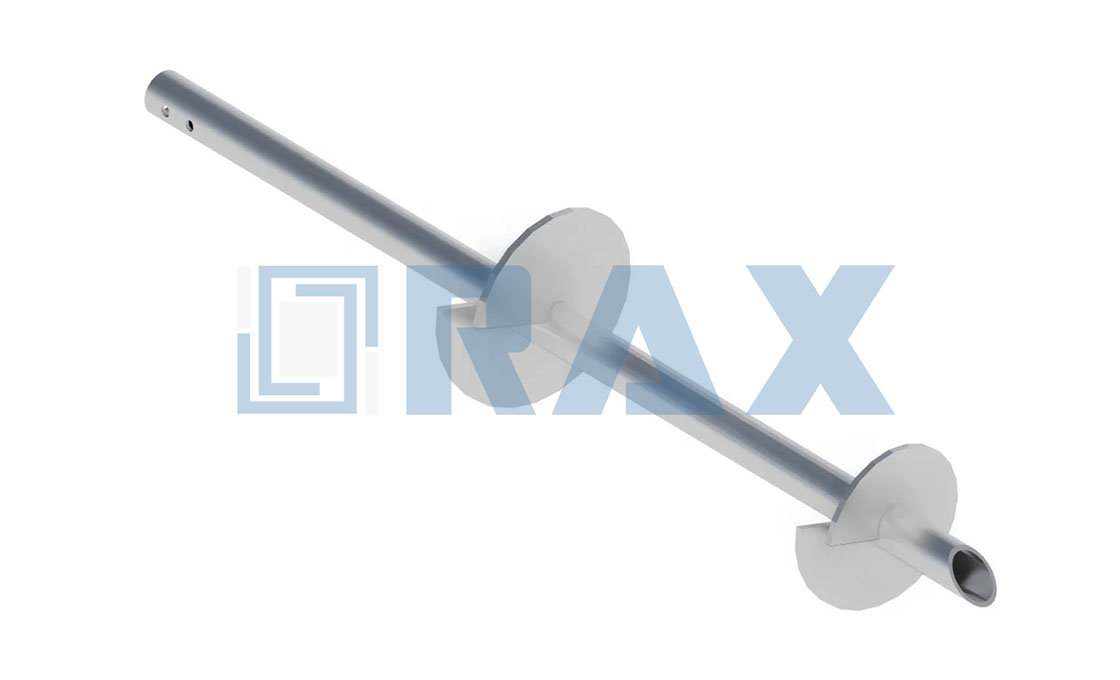

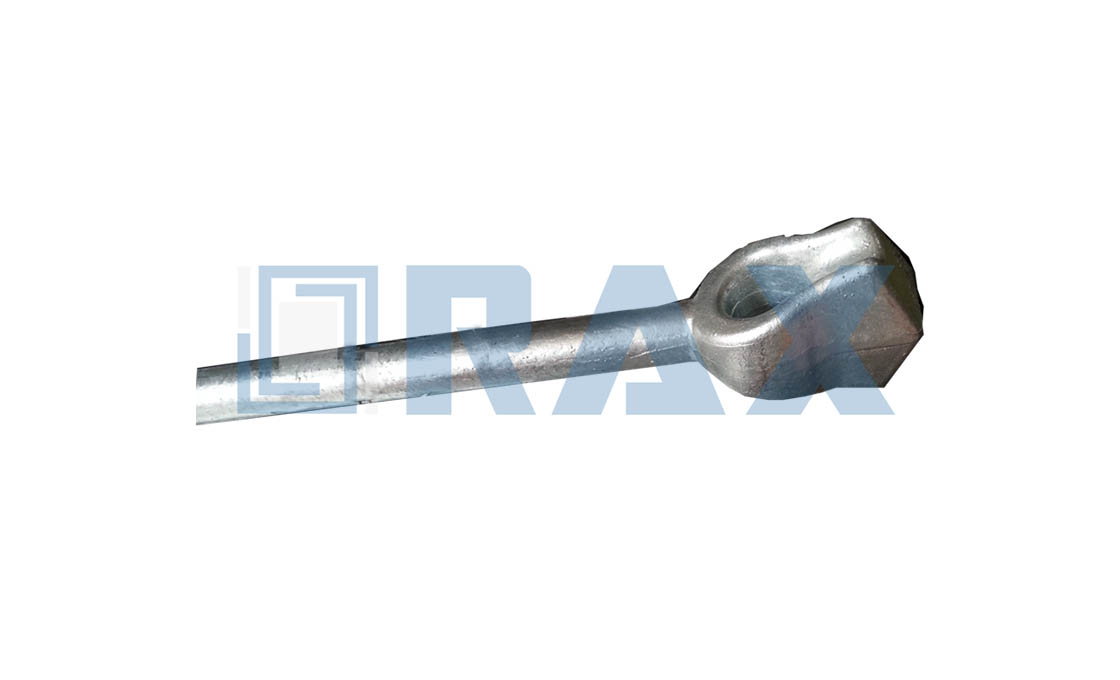

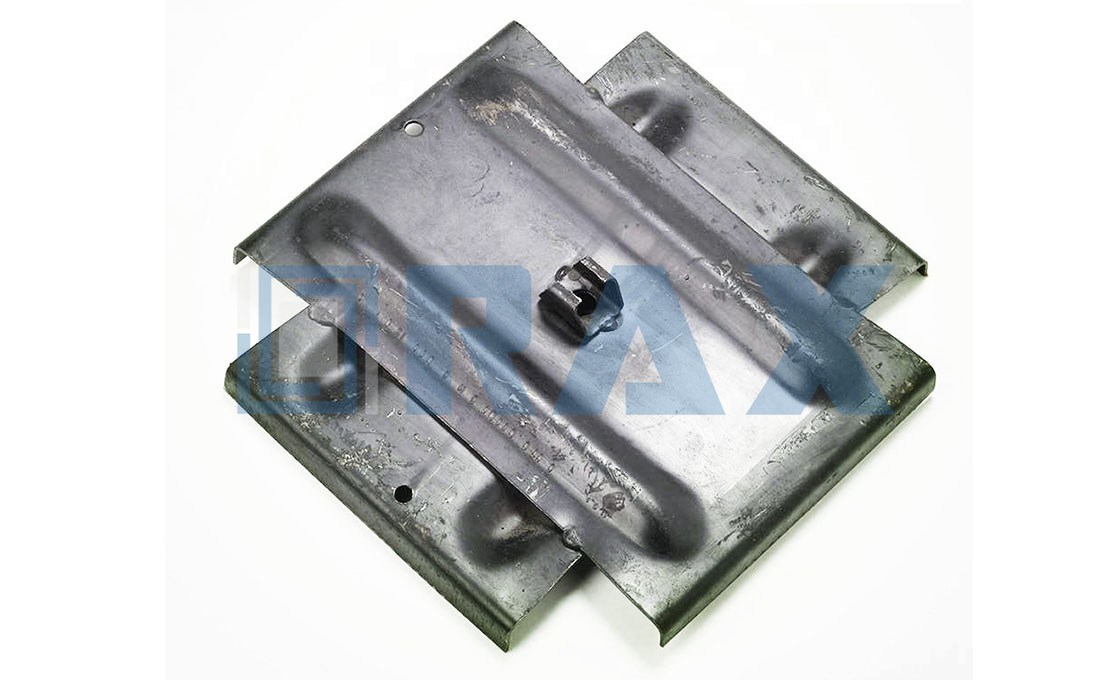

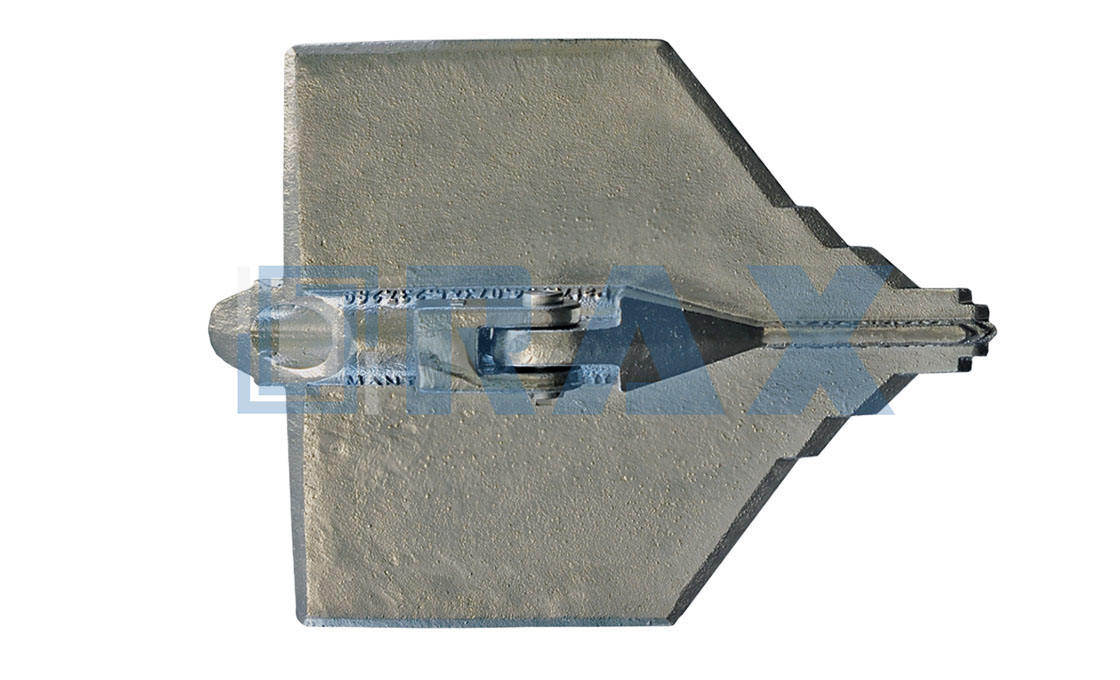

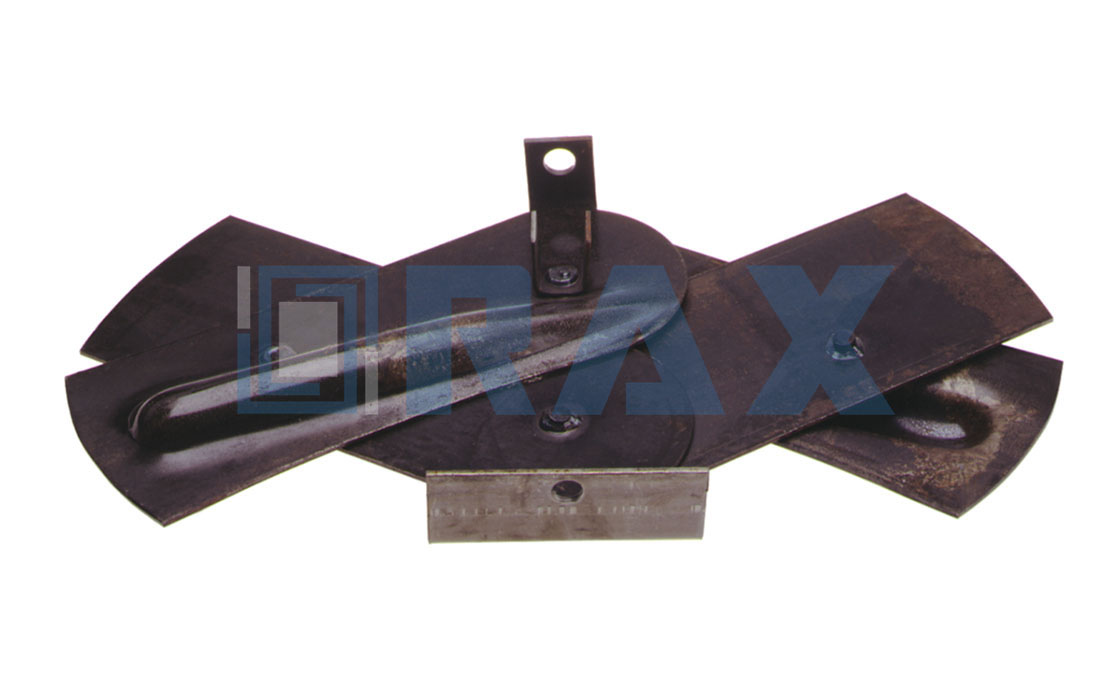

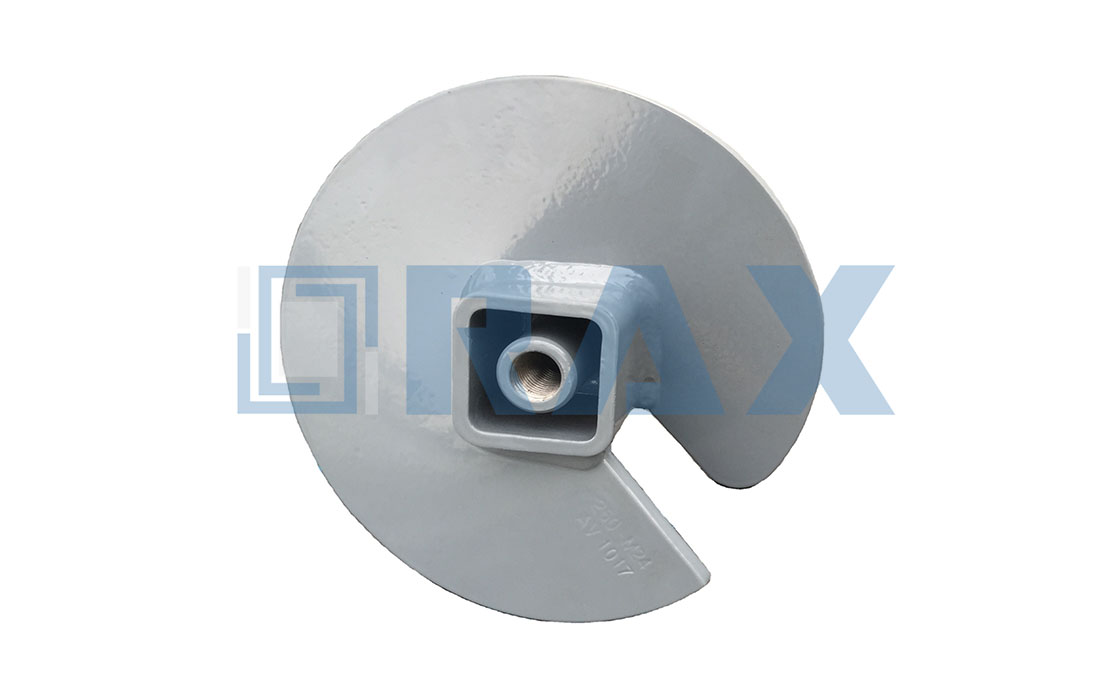

Components of the Helical Pulldown Micropile include a lead section with helical plates, extension sections, displacement plates, and a grout reservoir. To use this system, operators mount a hydraulically powered torque motor to standard excavation equipment. The HPM is versatile and can be customized to meet specific project requirements, making it suitable for various applications such as new construction, underpinning, and projects in limited access areas. Its design eliminates the need for spoil removal, allowing for efficient installation of 40-50 piles per day with minimal site disturbance.

Key features:

- High load capacity exceeding 400,000 lbs.

- Resistance to buckling in weak soils

- Stiffer piles that deflect less under load

- Additional corrosion protection for aggressive soil conditions

Customizable sizes and configurations available

Frequently Asked Questions (FAQ)

What is a Helical Pulldown Micropile?

The Helical Pulldown Micropile is a foundation system that creates a grout column around the shaft of a helical anchor. It utilizes helical plates to advance into the soil, displacing it and allowing for immediate grout filling, which encapsulates the shaft and enhances load-bearing capacity without the need for spoil removal.

How does the installation process work?

Installation begins by placing a helical anchor into the soil using torque. As the lead section penetrates, a Lead Displacement Plate is added, which pulls soil outward to create a cylindrical void. Grout is then injected to fill this void, forming a strong and stable foundation.

What are the advantages of using Helical Pulldown Micropiles?

Helical Pulldown Micropiles offer several benefits, including resistance to buckling in weak soils, higher load capacities, and additional corrosion protection in aggressive environments. They also allow for quick installation with minimal site disturbance.

What are the standard sizes of Helical Pulldown Micropiles?

Standard sizes typically range from 5 to 12 inches in diameter and lengths of 7 feet or more. As a leading manufacturer, we can customize sizes according to specific project requirements to ensure optimal performance.

In what applications are Helical Pulldown Micropiles commonly used?

These micropiles are versatile and suitable for various applications, including new construction, foundation repair, and projects in limited access areas. They are ideal for sites with weak surface soils where traditional foundations may fail.

Are there any limitations to using Helical Pulldown Micropiles?

While highly effective, Helical Pulldown Micropiles may not be suitable for all soil types or extreme load conditions. A thorough site assessment is necessary to determine their appropriateness for specific projects.