Insulator Side Tie

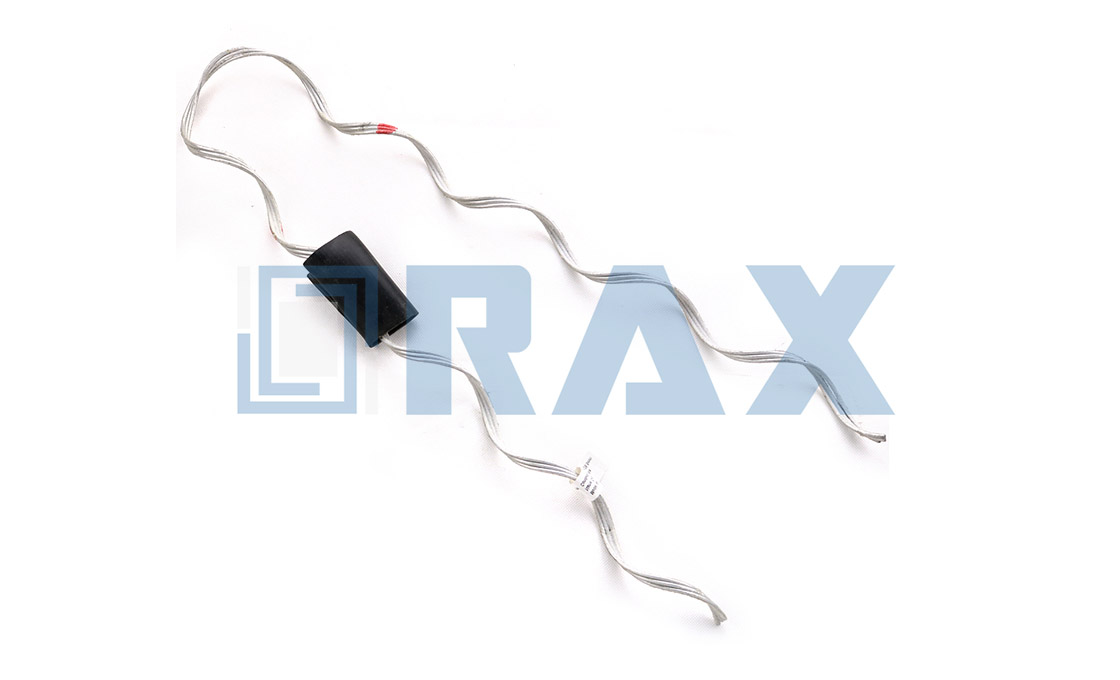

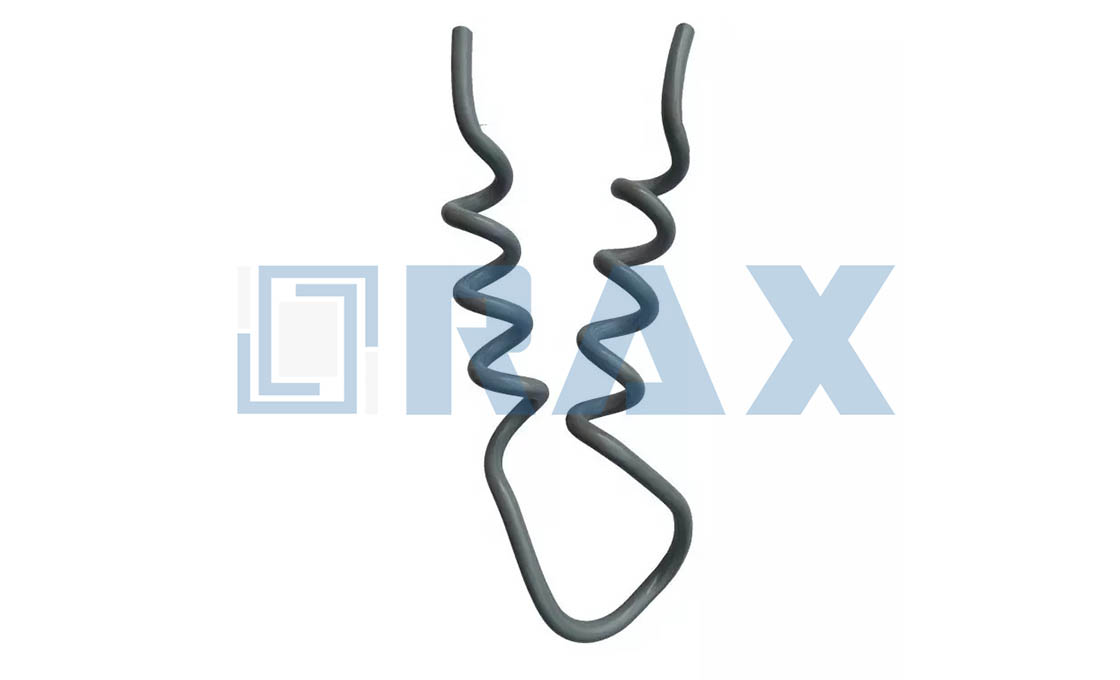

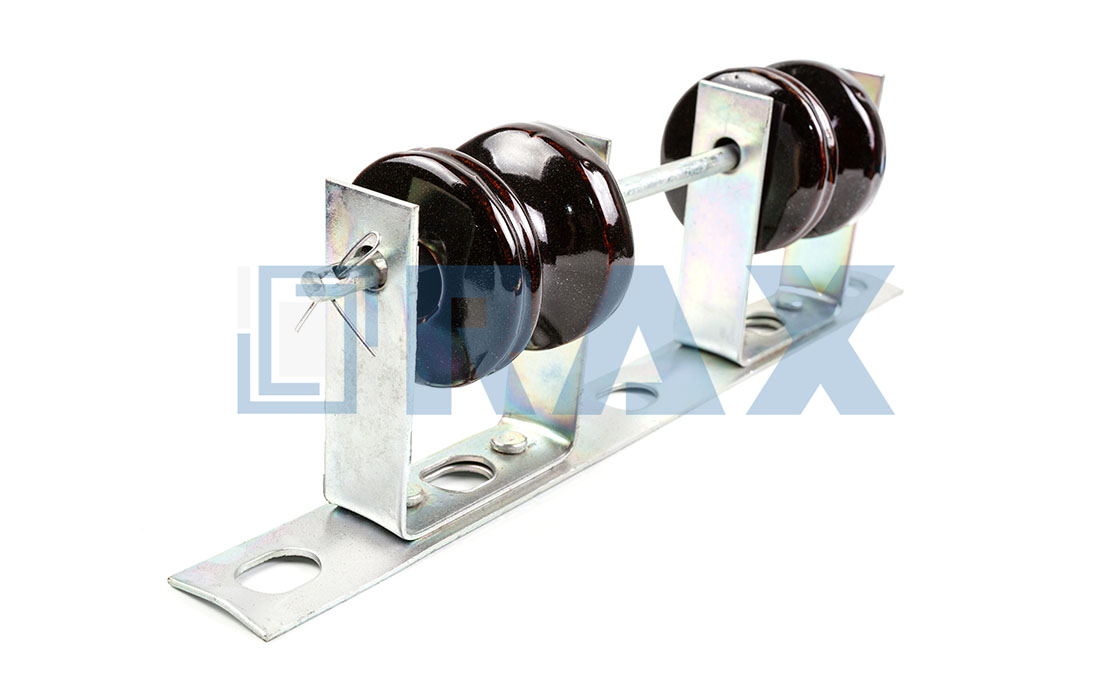

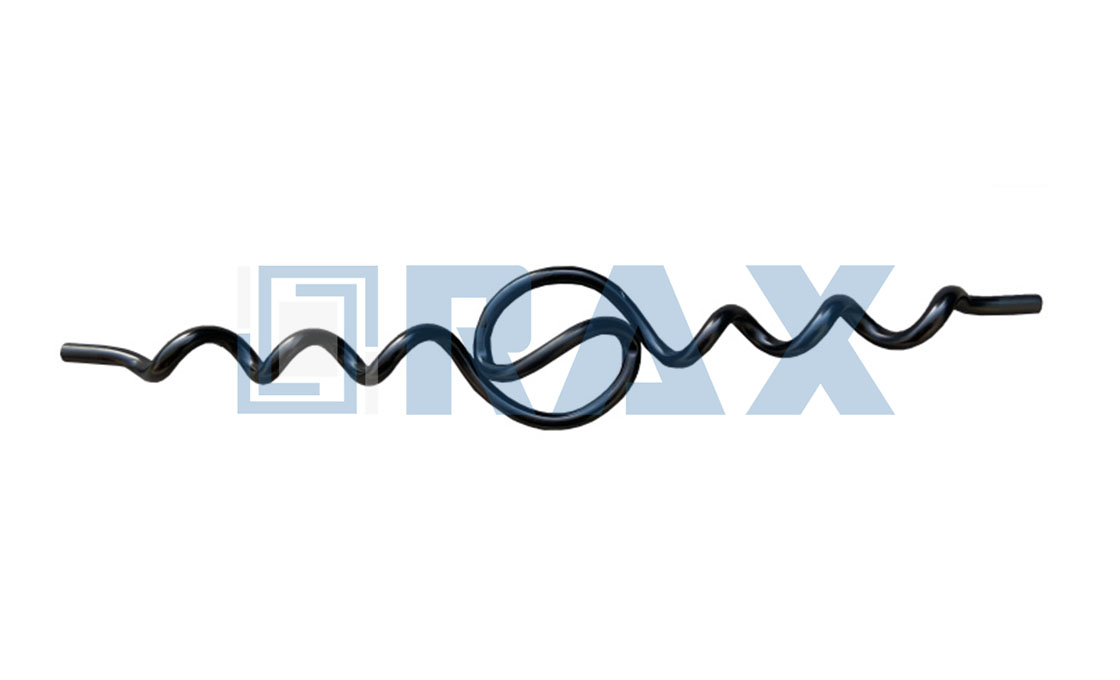

Insulator Side Ties, also known as distribution side ties or preformed side ties, are specialized components designed to secure conductors to the side groove of insulators in power distribution systems. These ties are manufactured from aluminum-clad steel wire, PVC, or semi-conductor materials, featuring a main tie component, protective pad, and identification tags. Side ties come in various types including single side ties, double side ties with elastomeric tubes, and groove-formed ties, each suited for different mounting configurations and conductor sizes.

When installing insulator side ties, they are mounted to secure conductors in the side groove of interchangeable insulators, capable of accommodating line angles up to 10° on horizontally-mounted installations. Side ties work effectively with various conductor types including ACSR, Compacted ACSR, All Aluminum, and plastic jacketed conductors, providing essential mechanical support while maintaining proper electrical isolation. The installation typically involves wrapping the tie around both the conductor and insulator, with some slack allowed for movement during high winds.

Key Features:

• Superior mechanical strength exceeding National Electric Safety Code requirements

• Elastomeric tube protection for enhanced abrasion resistance

• Field-adjustable design for various conductor sizes

• Excellent vibration dampening capabilities

• Compatible with both bare and jacketed conductors

• Corrosion-resistant construction for extended service life

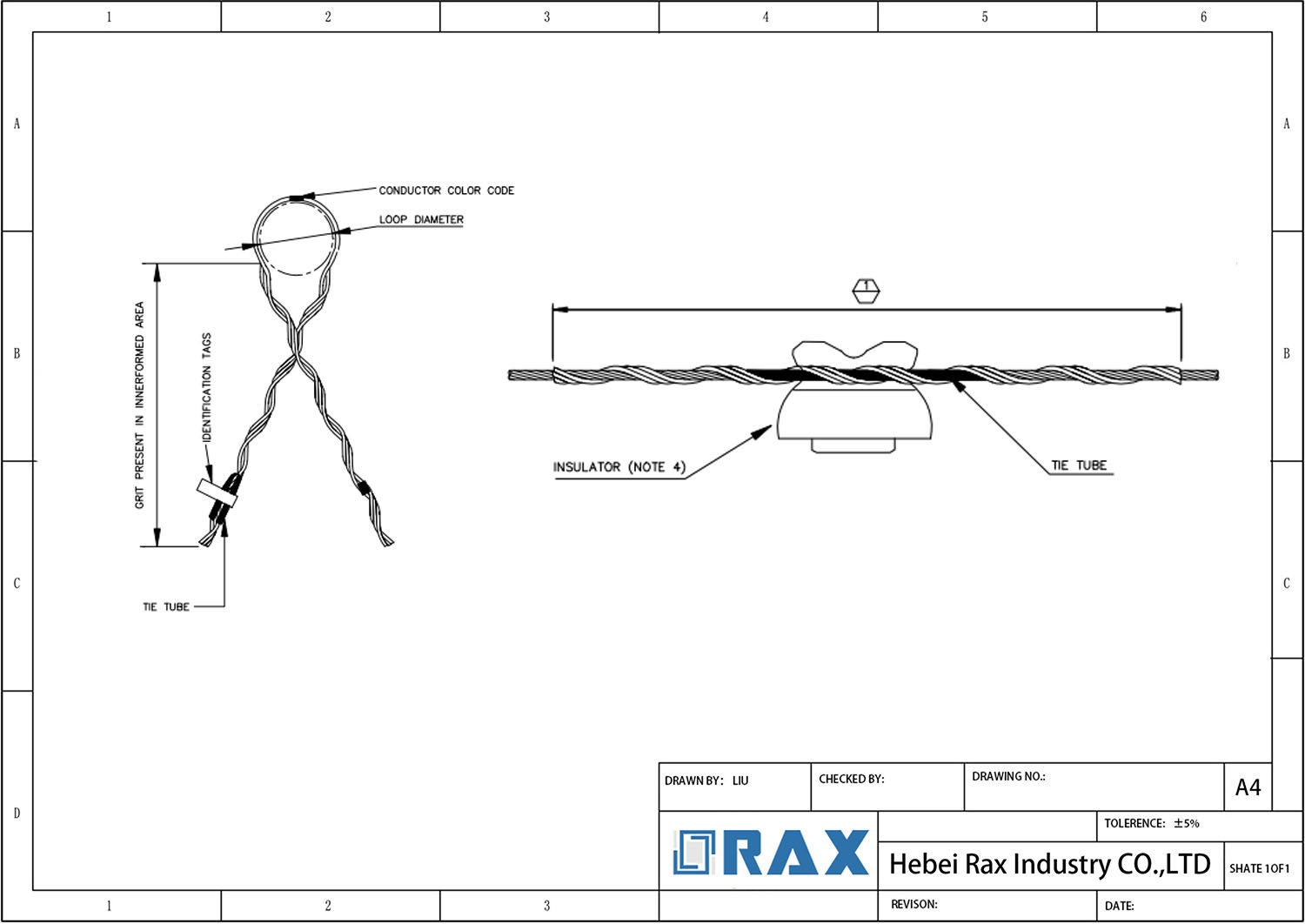

PVC Plastic Side Tie Drawing

| Model | Conductor diameter range (mm) | Length (mm) | Color

code |

|||

| C Neck (Φ57mm) | F Neck (Φ73mm) | Minimum | Maximum | C Neck | F Neck | |

| PSCB-57-1016 | PSCB-73-1016 | 7.52 | 10.16 | 560 | 560 | White |

| PSCB-57-1372 | PSCB-73-1372 | 10.19 | 13.72 | 535 | 610 | Green |

| PSCB-57-1854 | PSCB-73-1854 | 13.74 | 18.54 | 585 | 610 | Blue |

| PSCB-57-2337 | PSCB-73-2337 | 18.57 | 23.37 | 610 | 455 | Orange |

| PSCB-57-2794 | PSCB-73-2794 | 23.39 | 27.94 | 685 | 485 | Red |

| PSCB-57-3302 | PSCB-73-3302 | 27.97 | 33.02 | 760 | 535 | Black |

| PSCB-57-3810 | PSCB-73-3810 | 33.05 | 38.10 | 760 | 585 | Brown |

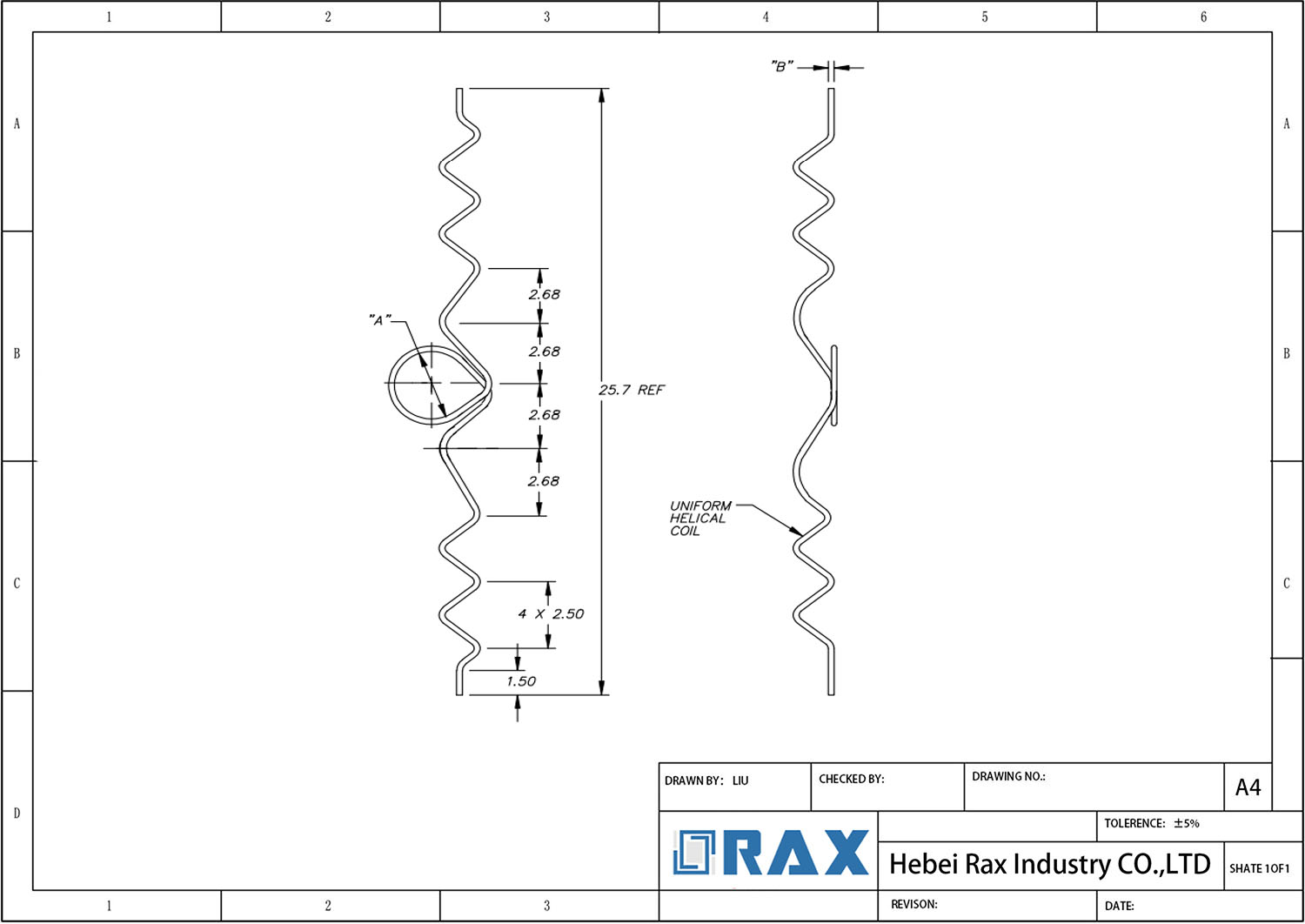

Formed Wire Side Tie Drawing

| ST CAT NO. | 1 | 2 | 3 | APPLICATION RANGE |

| APPLIED LENGTH | NECK SIZE | CONDUCTOR COLOR | ||

| LUKC4052AS | 19 | “C” Neck | ORANGE | 0.245 TO 0.277 (6.22 TO 7.04 mm) |

| LUAC4052ASN7 | ||||

| LUAC4054AS | 24 | “C” Neck | RED | 0.316 TO 0.357 (8.03 TO 9.08 mm) |

| LUKC4054ASN7 | ||||

| LUAC4055AS | 26 | “C” Neck | YELLOW | 0.358 TO 0.405 (9.09 TO 10.29 mm) |

| LUAC4055ASN7 | ||||

| LUAC4057AS | 31 | “C” Neck | ORANGE | 0.460 TO 0.520 (11.68 TO 13.21 mm) |

| LLAC4057ASN7 | ||||

| LUAC4058AS | 32 | “C” Neck | RED | 0.521 TO 0.588 (13.23 TO 14.95 mm) |

| LUAC4058ASN7 | ||||

| LUAC4060AS | 25 | “C” Neck | BROWN | 0.666 TO 0.755 (16.92 TO 19.18 mm) |

| LUAC406QASN7 | ||||

| LUAC4061AS | 26 | ”C” Neck | RED | 0.756 TO 0.855 (19.20 TO 21.72 mm) |

| LUAC4061ASN7 | ||||

| LUAC4062AS | 28 | “C” Neck | BLUE | 0.856 TO 0.968 (21.74 TO 24.59 mm) |

| LUAC4062ASN7 | ||||

| LUKF4550AS | 16 | “F” Neck | BLUE | 0.190 TO 0.215 (4.83 TO 5.46 mm) |

| LUAF455QASNT | ||||

| LUAF4551AS | 17 | “T” Neck | BROWN | 0.216 TO 0.244 (5.49 TO 6.20 mm) |

| LUAF4551ASNT | ||||

| LUKF4552AS | 19 | “F” Neck | ORANGE | 0.245 TO 0.277 (6.22 TO 7.04 mm) |

| LLAF4552ASNT | ||||

| LUAF4553AS | 21 | “T” Neck | PURPLE | 0.278 TO 0.315 (7.06 TO 8.00 mm) |

| LUAF4553ASNT | ||||

| LUAF4554AS | 24 | “T” Neck | RED | 0.316 TO 0.357 (8.03 TO 9.08 mm) |

| LUAF4554ASNT | ||||

| LUAF4555AS | 26 | “T” Neck | YELLOW | 0.358 TO 0.405 (9.09 TO 10.29 mm) |

| LUAF4555ASNT | ||||

| LUAF4556AS | 28 | “F” Neck | BLUE | 0.406 TO 0.459 (10.31 TO 11.66 mm) |

| LUAF4556ASNT | ||||

| LUAF4557AS | 30 | “F” Neck | ORANGE | 0.460 TO 0.520 (11.68 TO 13.21 mm) |

| LUAF4557ASNT | ||||

| LUAF4558AS | 32 | “F” Neck | RED | 0.521 TO 0.588 (13.23 TO 14.95 mm) |

| LUAF4558ASNT | ||||

| LUAF4559AS | 23 | “F” Neck | PURPLE | 0.589 TO 0.665 (14.96 TO 16.89 mm) |

| LUAF4559ASNT | ||||

| LUAF456QAS | 25 | “F” Neck | BROWN | 0.666 TO 0.755 (16.92 TO 19.18 mm) |

| LUAF4560ASNT | ||||

| LUAF4561AS | 26 | “F” Neck | RED | 0.756 TO 0.855 (19.20 TO 21.72 mm) |

| LUAF4561ASNT | ||||

| LUAF4562AS | 28 | “F” Neck | BLUE | 0.856 TO 0.968 (21.74 TO 24.59 mm) |

| LUAF4562ASNT | ||||

| LUAF4563AS | 29 | “F” Neck | GREEN | 0.969 TO 1.096 (24.61 TO 27.85 mm) |

| LUAF4563ASNT |

Frequently Asked Questions (FAQ)

What is an insulator side tie?

What is an insulator side tie?

An insulator side tie is a component used in overhead electrical installations to secure conductors to the side groove of insulators. It wraps around both the conductor and the insulator, preventing the conductor from moving or detaching. Side ties are typically made of durable materials like aluminum or copper to ensure electrical stability and safety.

How does a side tie differ from other insulator ties?

Side ties attach conductors to the side groove of insulators, while top ties secure conductors to the top groove. Spool ties are used specifically with spool insulators. Each type is designed for different insulator configurations and mounting positions on utility poles or towers.

What are the main functions of a side tie?

Side ties secure conductors to insulators, maintain electrical continuity, reduce conductor vibrations, handle mechanical loads, and accommodate thermal expansion and contraction. They also support insulation, enhance safety and reliability, and facilitate easy maintenance and inspection of power systems.

What materials are commonly used for side ties?

Side ties are typically made from materials such as aluminum, aluminum alloy, galvanized steel, or copper. These materials are chosen for their good electrical conductivity, corrosion resistance, and durability. The material selected should be compatible with the conductor to avoid galvanic corrosion.

How do you install a side tie?

To install a side tie, first ensure proper safety measures. Position the conductor on the insulator’s side groove, then wrap the preformed side tie around both. For hand-tied side ties, wrap manually and twist the ends to secure. Finally, adjust for tightness and inspect for proper installation.

What factors should be considered when choosing a side tie?

When selecting a side tie, consider factors such as conductor size, insulator type, line angle, environmental conditions, and load requirements. Ensure the side tie’s material, design, and specifications are compatible with your specific application and meet relevant industry standards.

How do side ties handle line angles?

Side ties can accommodate various line angles depending on the insulator mounting. On vertically-mounted insulators, they typically handle angles up to 10 degrees. The specific angle capacity depends on factors like conductor size, insulator orientation, and tie design.

What is an insulator side tie?

What is an insulator side tie?