Spool Tie

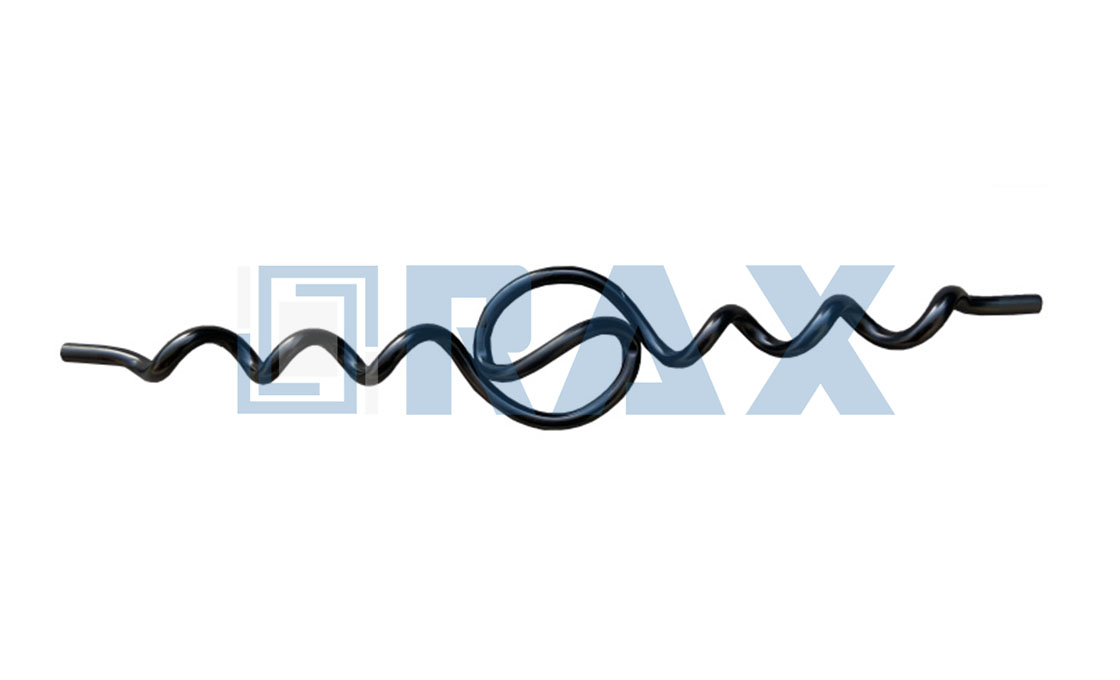

Spool Ties are specialized components designed to secure conductors to spool insulators in power distribution systems. These ties, also known as distribution ties, are typically manufactured from aluminum-clad steel wire and feature a main tie component, protective padding, and identification tags. Spool Ties come in two main types: those with elastomeric pads for bare conductors and those without pads for jacketed conductors.

When installing Spool Ties, they are wrapped around both the conductor and the spool insulator, providing mechanical support while maintaining proper electrical isolation. Spool Ties work effectively with various conductor types including ACSR, AAC, AAAC, and plastic jacketed conductors, accommodating conductor sizes up to 0.968″ in diameter. These ties are designed to replace hand ties over armor rods, offering superior performance and protection against conductor motion and abrasion.

Key Features of Spool Ties:

• Superior mechanical strength exceeding National Electric Safety Code requirements

• Elastomeric pad protection for enhanced abrasion resistance on bare conductors

• Preformed helical shape for easier and more uniform installation

• Improved Radio Interference Voltage (RIV) characteristics compared to hand ties

• Corrosion-resistant construction for extended service life

• Compatible with standard 1-3/4″ neck diameter spool insulators

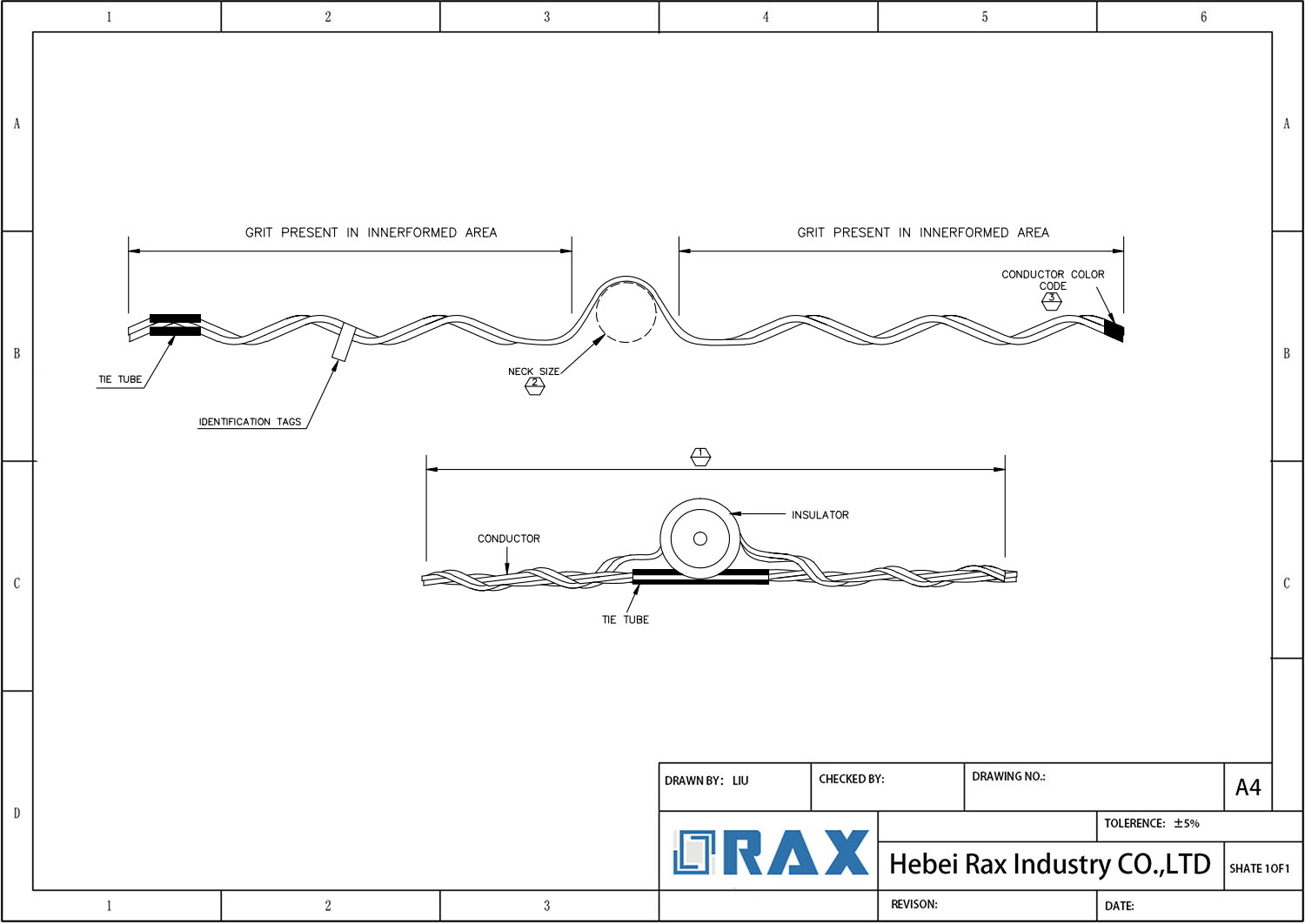

Spool Tie Drawing

| ST NO. | 1 | 2 | 3 | APPLICATION RANGE |

| APPLIED LENGTH | NECK SIZE | CONDUCTOR COLOR CODE | ||

| QWSP4372 | 19 | 1.77 | ORANGE | 0.245 TO 0.277 (6.22 TO 7.04 mm) |

| QWSP4372NT | ||||

| QWSP4374 | 24 | 1.77 | RED | 0.316 TO 0.357 (8.03 TO 9.07 mm) |

| QWSP4374NT | ||||

| QWSP4375 | 26 | 1.77 | YELLOW | 0.358 TO 0.405 (9.09 TO 10.29 mm) |

| QWSP4375NT | ||||

| QWSP4376 | 28 | 1.77 | BLUE | 0.406 TO 0.459 (10.31 TO 11.66 mm) |

| QWSP4376NT | ||||

| QWSP4377 | 31 | 1.77 | ORANGE | 0.460 TO 0.520 (11.68 TO 13.21 mm) |

| QWSP4377NT | ||||

| QWSP4378 | 32 | 1.77 | RED | 0.521 TO 0.588 (13.23 TO 14.94 mm) |

| QWSP4378NT | ||||

| QWSP4379 | 23 | 1.77 | PURPLE | 0.589 TO 0.665 (14.96 TO 16.89 mm) |

| QWSP4379NT | ||||

| QWSP4380 | 25 | 1.77 | BROWN | 0.666 TO 0.755 (16.92 TO 19.18 mm) |

| QWSP4380NT | ||||

| QWSP4381 | 32 | 1.77 | RED | 0.756 TO 0.858 (19.20 TO 21.79 mm) |

| QWSP4381NT |

Frequently Asked Questions (FAQ)

What is a spool tie?

What is a spool tie?

A spool tie is a preformed wire component designed to secure electrical conductors to spool-type insulators on utility poles or transmission towers. It replaces hand ties over armor rods and provides superior protection against abrasion and conductor motion, from high-frequency aeolian vibration to low-frequency galloping.

What materials are spool ties made of?

Spool ties are typically manufactured from aluminum-covered steel wire. For bare conductors, they include a specially formulated elastomeric pad or tie tube for abrasion protection. Spool ties without pads are used for jacketed conductors.

What are the key features of spool ties?

Key features include superior mechanical strength, resilience during conductor motion, elastomeric pad protection for bare conductors, preformed helical shape for easier installation, improved Radio Interference Voltage (RIV) characteristics, and corrosion-resistant construction for extended service life.

What types of conductors are compatible with spool ties?

Spool ties are compatible with various conductor types, including ACSR (Aluminum Conductor Steel Reinforced), AAC (All Aluminum Conductor), AAAC (All Aluminum Alloy Conductor), ACAR, Compacted ACSR, and plastic jacketed conductors. They can accommodate conductor sizes up to 0.968″ in diameter.

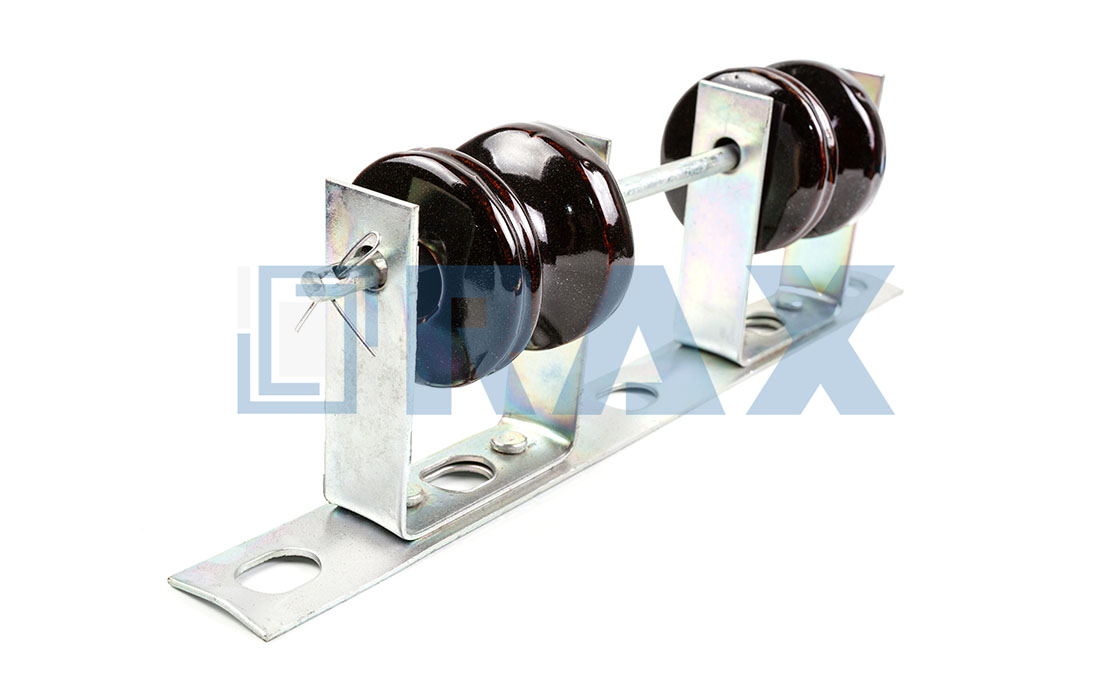

What insulator types are compatible with spool ties?

Spool ties are typically designed for use with ANSI Class 53-1, 53-2, and 53-3 spool insulators with 1-3/4″ neck diameters. Some manufacturers offer ties compatible with ANSI Class 53-4 and 53-5 insulators with 2-7/8″ neck diameters.

How are spool ties installed?

Spool ties are wrapped around both the conductor and the spool insulator. They can be mounted horizontally or vertically, with the conductor positioned to bear into the insulator. Installation is typically easier and more uniform than hand ties due to the preformed helical shape.

What line angles can spool ties accommodate?

On horizontally-mounted insulators, spool ties can normally accommodate line angles up to 10°. For vertically-mounted insulators, line angles up to 40° can typically be achieved. The maximum angle depends on factors such as conductor size, tension, span lengths, and insulator orientation.

What is a spool tie?

What is a spool tie?