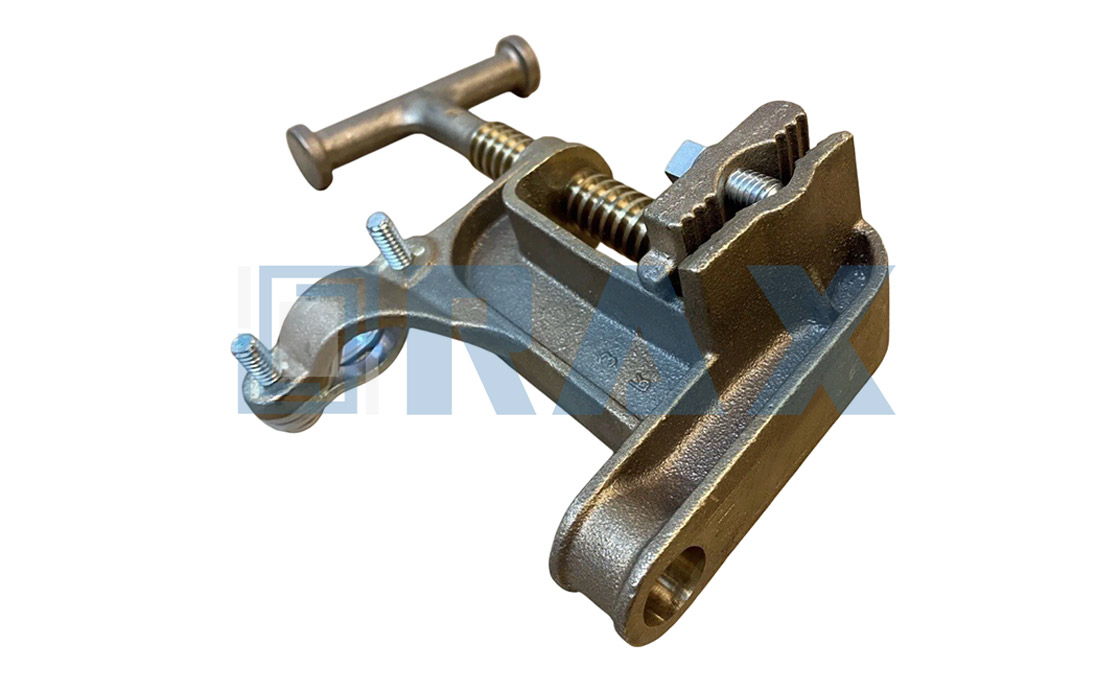

Flat Face Ground Clamp

The Flat Face Ground Clamp, also known as flat jaw grounding clamps, are designed to create a reliable electrical connection between equipment and the ground for grounding applications. They are commonly used in utility work, maintenance, and construction settings. The clamp features serrated jaws that enhance grip on surfaces, ensuring a secure connection. Users can easily operate the clamp by tightening its fine-thread eye screw or using a T-handle for added leverage.

To utilize the Flat Face Ground Clamp, position it on the desired surface and tighten it securely. It can be used with various equipment, including grounding rods, angle iron, and bus bars. This clamp is available in different sizes, allowing customization based on specific requirements. Its robust structure and materials, such as aluminum and stainless steel components, ensure durability and reliability in demanding environments.

Key Features:

• Serrated jaws for enhanced grip

• Fine-thread eye screw for easy adjustment

• Lightweight aluminum construction

• Customizable sizes available

• Suitable for various grounding applications

Frequently Asked Questions (FAQ)

What is a Flat Face Ground Clamp?

A Flat Face Ground Clamp is a device used in electrical grounding to ensure a secure connection between a grounding conductor and an electrical component. It features a flat jaw design that provides maximum surface contact, which is essential for effective grounding.

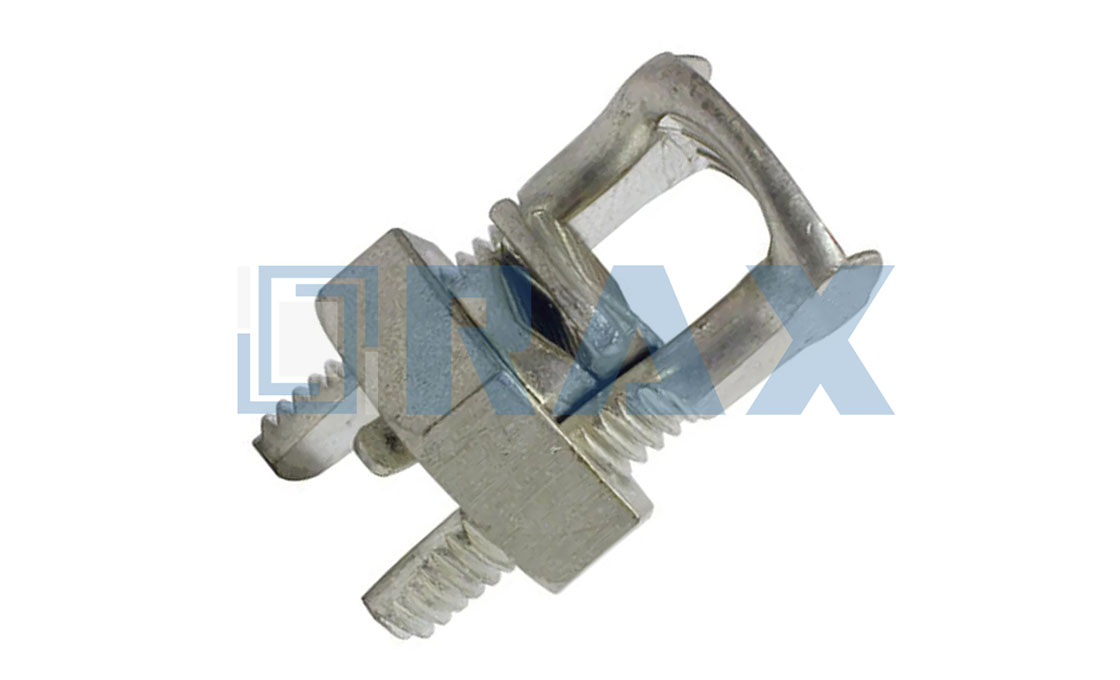

What materials are Flat Face Ground Clamps made of?

Flat Face Ground Clamps are typically made from materials like aluminum or bronze. These materials are chosen for their excellent conductivity and resistance to corrosion, ensuring durability and reliability in various environmental conditions.

What are the standard sizes of Flat Face Ground Clamps?

Standard sizes for Flat Face Ground Clamps generally include jaw openings of 1.25 inches, 1.5 inches, and 2 inches. We are a leading manufacturer that can customize clamps according to specific requirements, ensuring they meet your unique needs.

How do you install a Flat Face Ground Clamp?

To install a Flat Face Ground Clamp, first clean the surface of the conductor to remove any contaminants. Open the clamp, position it over the conductor, and then tighten it securely using the provided mechanism, ensuring good electrical contact.

What is the maximum fault current rating for Flat Face Ground Clamps?

The maximum fault current rating for Flat Face Ground Clamps can vary but typically ranges from 30kA to 43kA for short durations. This rating indicates the clamp’s ability to handle high fault currents without failure during electrical faults.

Are Flat Face Ground Clamps adjustable?

Yes, many Flat Face Ground Clamps come with adjustable features such as eye screws or T-handles. This adjustability allows for secure attachment to various conductor sizes and configurations, enhancing versatility in different applications.

Can Flat Face Ground Clamps be used on different conductor types?

Flat Face Ground Clamps are designed to work with various conductor types, including copper and aluminum cables. It’s important to ensure that the clamp’s material is compatible with the conductor type to prevent galvanic corrosion.