Arcing Horn

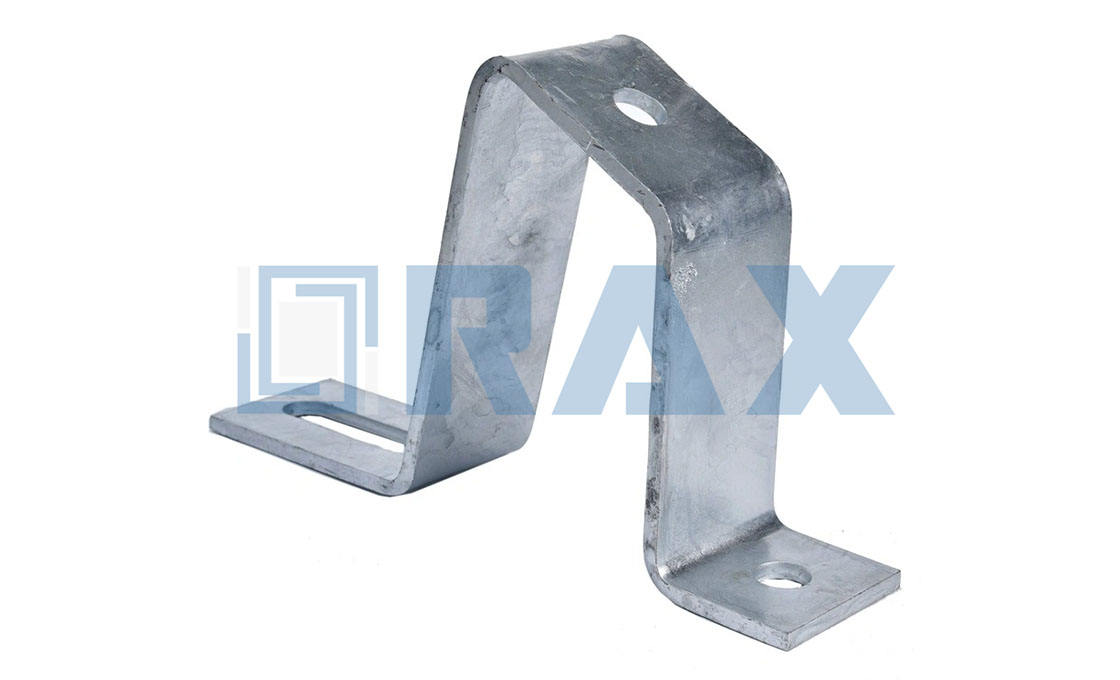

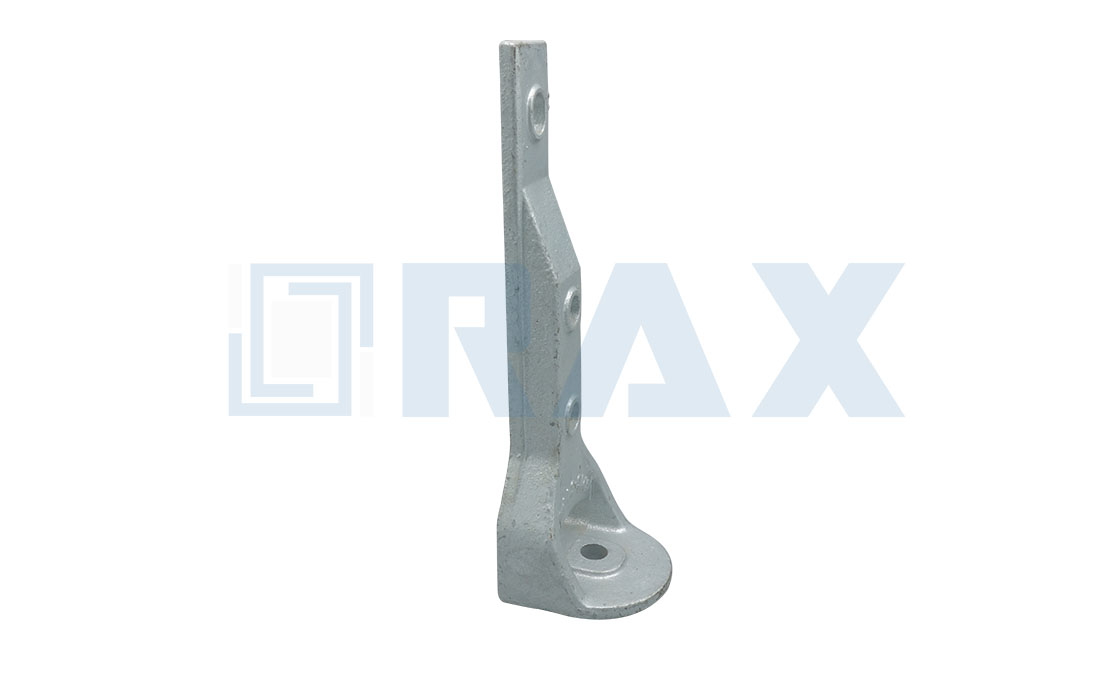

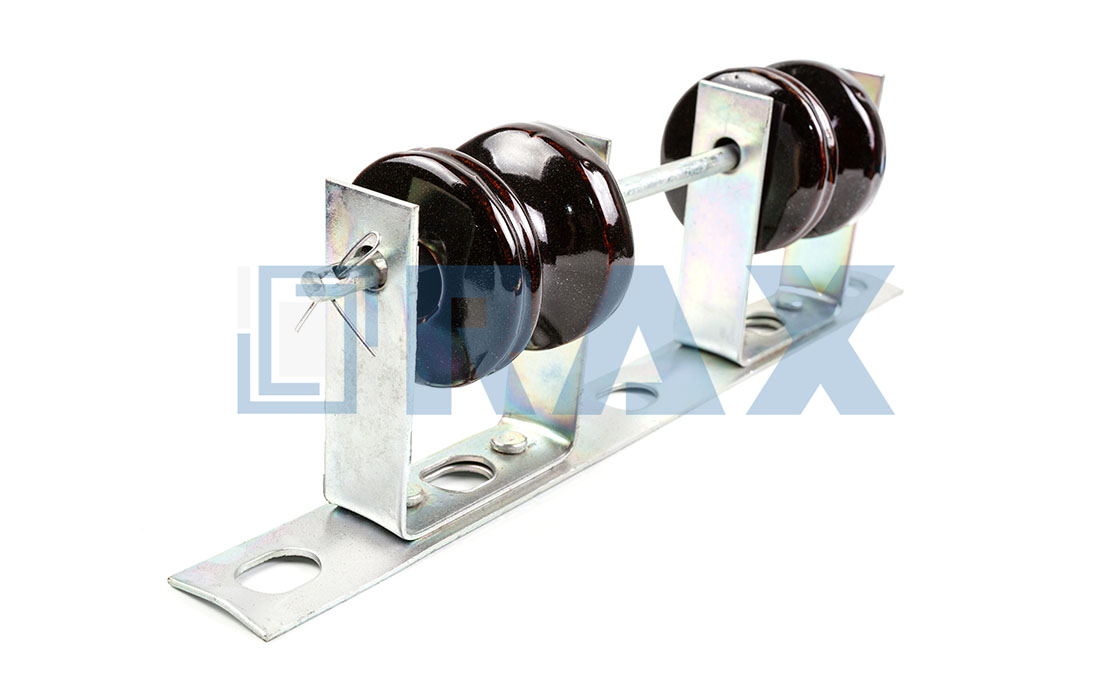

The Arcing Horn, also known as an arc horn or horn gap, is a type of projecting conductor in high voltage electrical systems. These devices are primarily employed to protect insulators and switch hardware from damage during flashover events caused by overvoltages, such as those from lightning strikes or electrical faults. Arcing horns create a controlled path for electrical arcs to follow, effectively diverting them away from sensitive equipment. They are typically constructed from galvanized steel or aluminum alloy and can be customized to meet specific voltage and installation requirements.

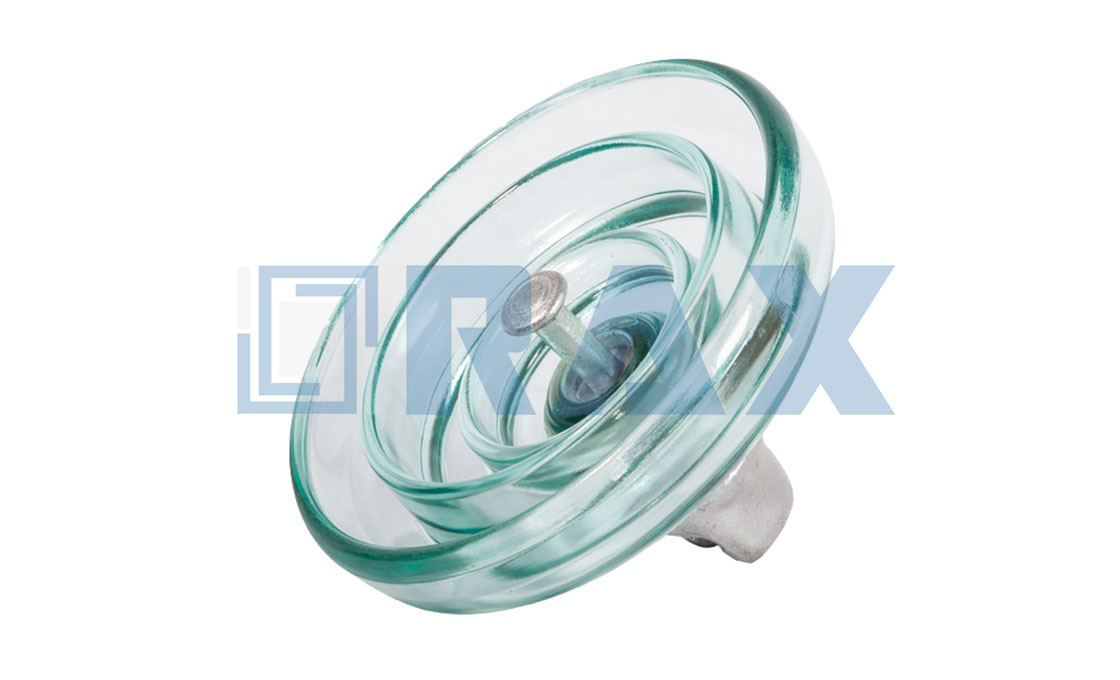

To use the Arcing Horn, it is installed on either side of an insulator string, with one horn connected to the high voltage side and the other grounded. The design allows for a spark gap that has a lower breakdown voltage than the insulator surface, ensuring that any overvoltage will result in an arc forming between the horns rather than across the insulator. This setup minimizes damage and provides time for fault detection and circuit interruption. Arcing horns are compatible with various insulator types, including heavy suspension and tension insulators, making them versatile for different applications in overhead transmission lines.

Key features:

- Provides effective protection against overvoltage events

- Customizable sizes to fit specific voltage requirements

- Durable construction from galvanized steel or aluminum alloy

- Designed to create a controlled arc path away from insulators

-

Compatible with various types of insulators and switchgear systems

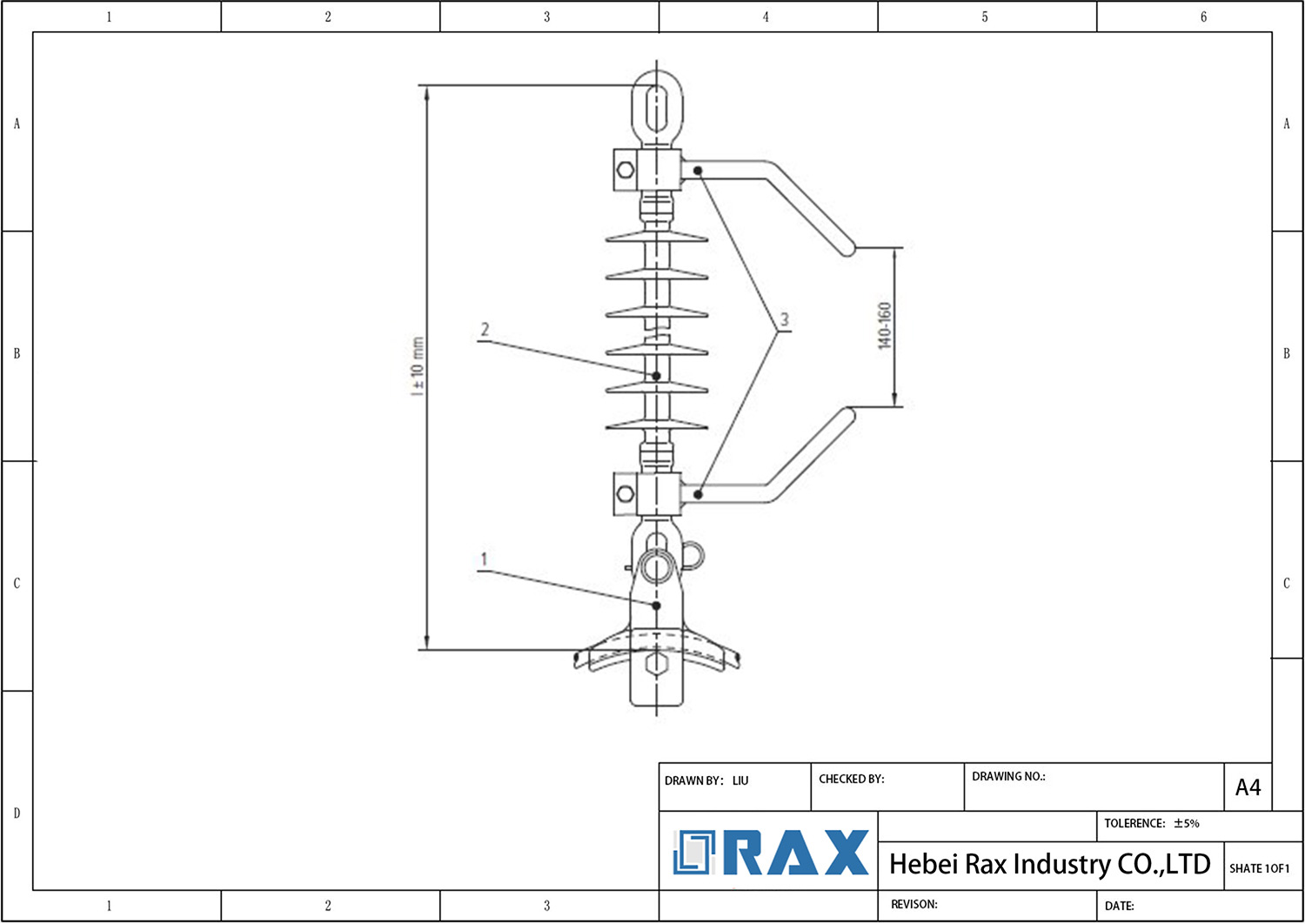

Arcing Horn Drawing

Frequently Asked Questions (FAQ)

What are arcing horns and their purpose?

What are arcing horns and their purpose?

Arcing horns are protective devices installed on high voltage insulators to prevent damage during electrical flashovers. They create a controlled path for electrical surges, allowing them to bypass the insulator and protect it from high voltage stress, thereby enhancing the reliability of power transmission systems.

How do arcing horns work?

Arcing horns consist of two conductors separated by an air gap. When an overvoltage occurs, the air between the horns ionizes, creating a conductive path for the surge. This allows the arc to form between the horns instead of across the insulator, thus preventing potential damage.

What materials are arcing horns made from?

Arcing horns are typically constructed from hot-dip galvanized steel or aluminum alloy. These materials provide strength and resistance to corrosion, ensuring longevity and reliability in harsh outdoor environments.

How do I install arcing horns on insulators?

Installation involves securely attaching the arcing horns to the designated points on the insulator while ensuring they maintain proper spacing for effective operation. It is crucial to follow manufacturer guidelines to achieve optimal performance and safety standards.

Can I customize my order of arcing horns?

Yes! We specialize in manufacturing custom arcing horns tailored to meet specific project needs. Customers can specify dimensions, materials, and other requirements to ensure compatibility with their systems.

Can arcing horns be used in all voltage applications?

While arcing horns are primarily used in medium and high voltage applications, their design may vary based on specific voltage requirements. For low voltage systems, the risk of arcing is reduced, and thus they may not be necessary. Always consult with a professional for appropriate applications.

What are arcing horns and their purpose?

What are arcing horns and their purpose?