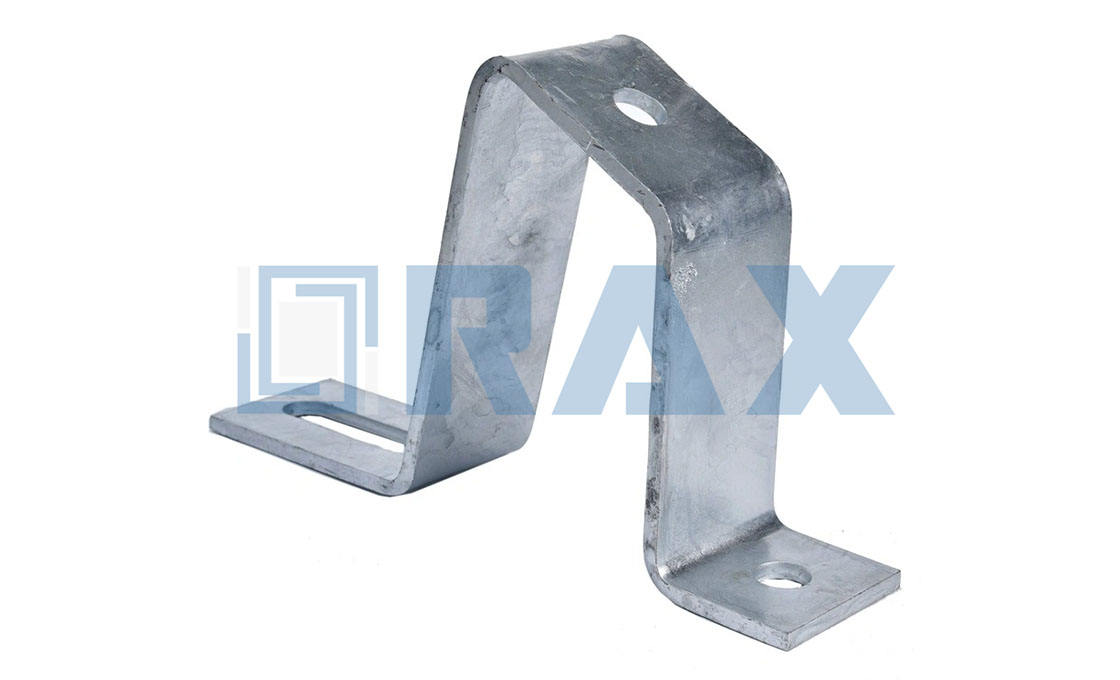

Transformer Lead Pin

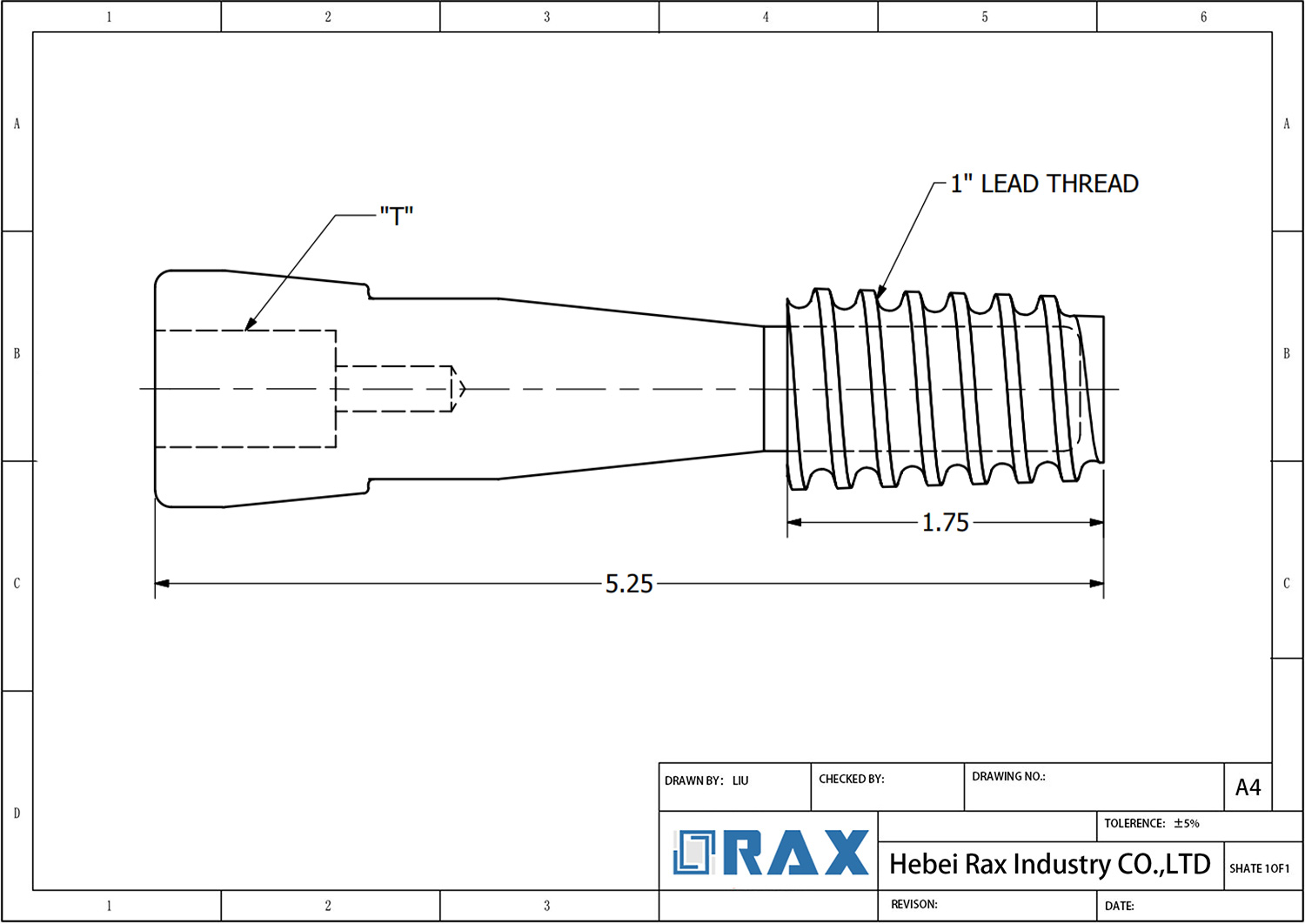

The Transformer Lead Pin is a type of insulator pin designed to connect transformer leads to pin-type insulators in electrical systems. It ensures a secure and efficient connection, supporting power transfer in transformers while maintaining mechanical stability. These pins are commonly used with ANSI-standard insulators and are compatible with various transformer types, including step-up and step-down transformers. Constructed with durable materials like hot-dip galvanized steel or cast lead threads, the product is engineered to withstand demanding environments and ensure long-term reliability.

Available in multiple sizes and configurations, the Transformer Lead Pin can be tailored to meet specific application needs. It is often referred to as a lead adapter or transformer lead connector. The product is threaded on the end of a 5/8-inch machine bolt, making it easy to install into standard pin-type insulators. Its adaptability allows it to function seamlessly in diverse setups, such as laminated core transformers or multiple winding transformers, ensuring compatibility across various power distribution systems.

Using the Transformer Lead Pin is straightforward. Simply screw it into the insulator’s threaded hole and attach the transformer lead securely. This pin is ideal for high-voltage applications where both electrical insulation and mechanical support are critical. Its robust design ensures safe operation while maintaining optimal performance in utility infrastructures and industrial power systems.

Key Features

- Durable Materials: Constructed from stainless steel or cast lead for strength and longevity.

- Standard Compatibility: Fits ANSI-standard pin-type insulators with 1-inch or 1 3/8-inch threads.

- Versatile Applications: Suitable for step-up, step-down, and multiple winding transformers.

- Easy Installation: Threaded design allows quick and secure attachment to insulators.

- Reliable Performance: Ensures safe and efficient power transfer in high-voltage environments.

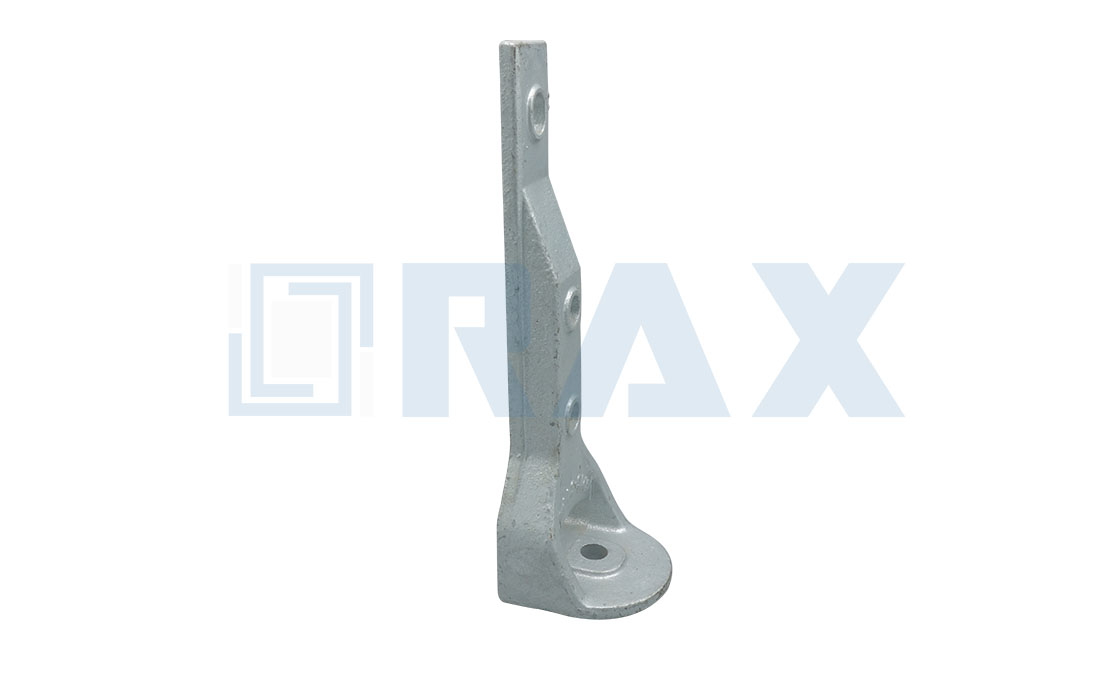

Transformer Lead Pin Drawing

Frequently Asked Questions (FAQ)

What is a Transformer Lead Pin?

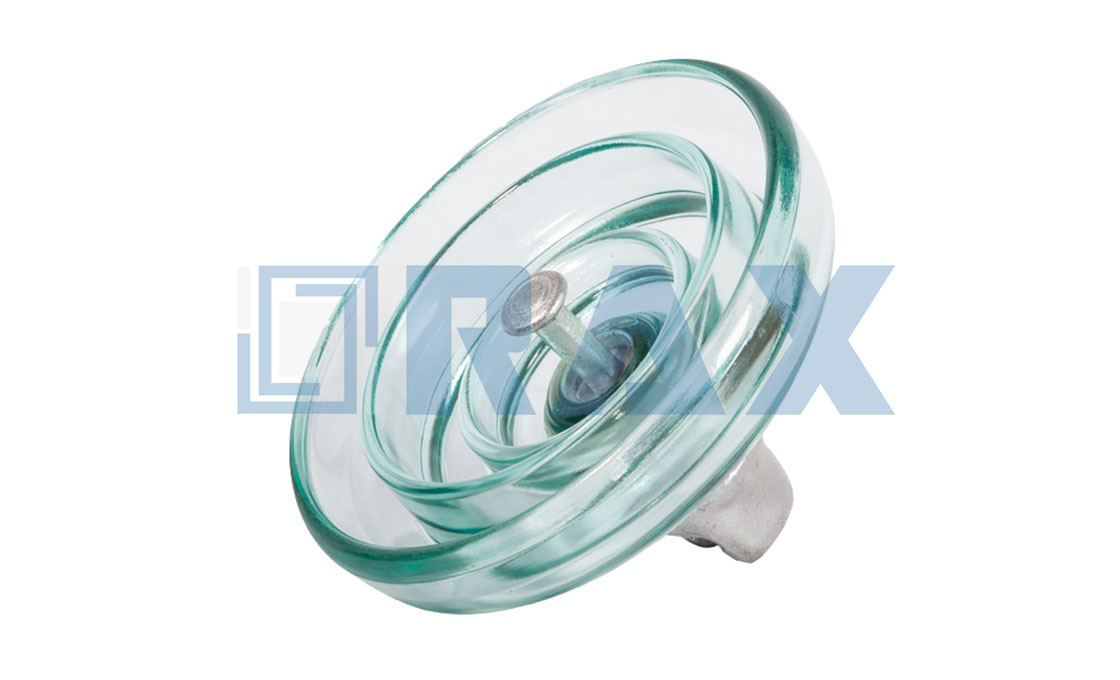

A transformer lead pin is a hardware component used to carry electrical leads to a transformer. It typically features molded threads for compatibility with insulators and ensures secure connections for reliable transformer operation.

How is a Transformer Lead Pin Installed?

Transformer lead pins are mounted using bolts or threaded connections. They are designed to securely grip the transformer’s lead wires, often in conjunction with other hardware like insulator brackets or clamps.

What Materials Are Used for Transformer Lead Pins?

Transformer lead pins are commonly made from hot-dip galvanized steel or nylon alloy. These materials provide durability, corrosion resistance, and strength for outdoor and industrial applications.

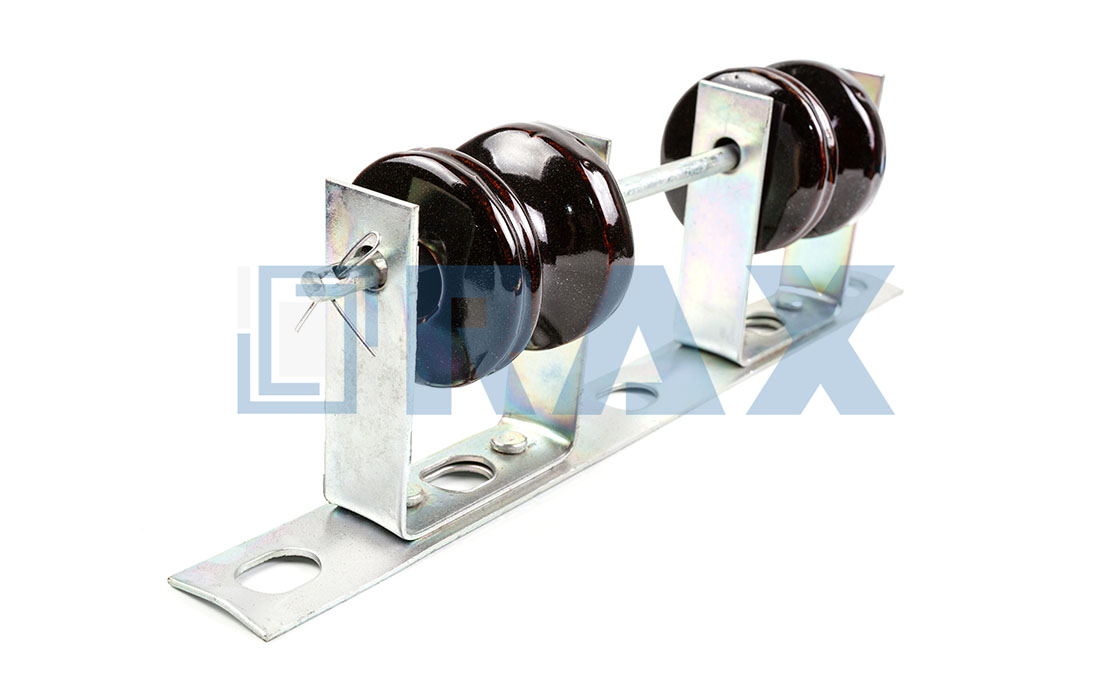

What Are the Common Applications of Transformer Lead Pins?

Transformer lead pins are primarily used in electrical utility systems for carrying and securing leads to transformers. They are also employed in cable suspension systems and pole line hardware setups.

What Thread Standards Are Used in Transformer Lead Pins?

Transformer lead pins often follow ANSI standards for threading, such as 1-inch threads, ensuring compatibility with standard insulators and other hardware components.

How Do You Test the Polarity of Transformer Coil Pins?

To test polarity, connect a 9V battery to the primary coil and measure voltage spikes on the secondary coil using a voltmeter. Reversing battery polarity helps identify the correct orientation based on maximum voltage output.

What Are the Key Features of High-Quality Transformer Lead Pins?

High-quality transformer lead pins feature strong materials like galvanized steel, precise threading for insulator compatibility, resistance to environmental conditions, and compliance with industry standards such as ISO9001.

Can Transformer Lead Pins Be Customized?

Yes, transformer lead pins can be customized based on specific requirements, such as unique threading, material coatings, or dimensions. Custom packaging options may also be available for specialized needs.