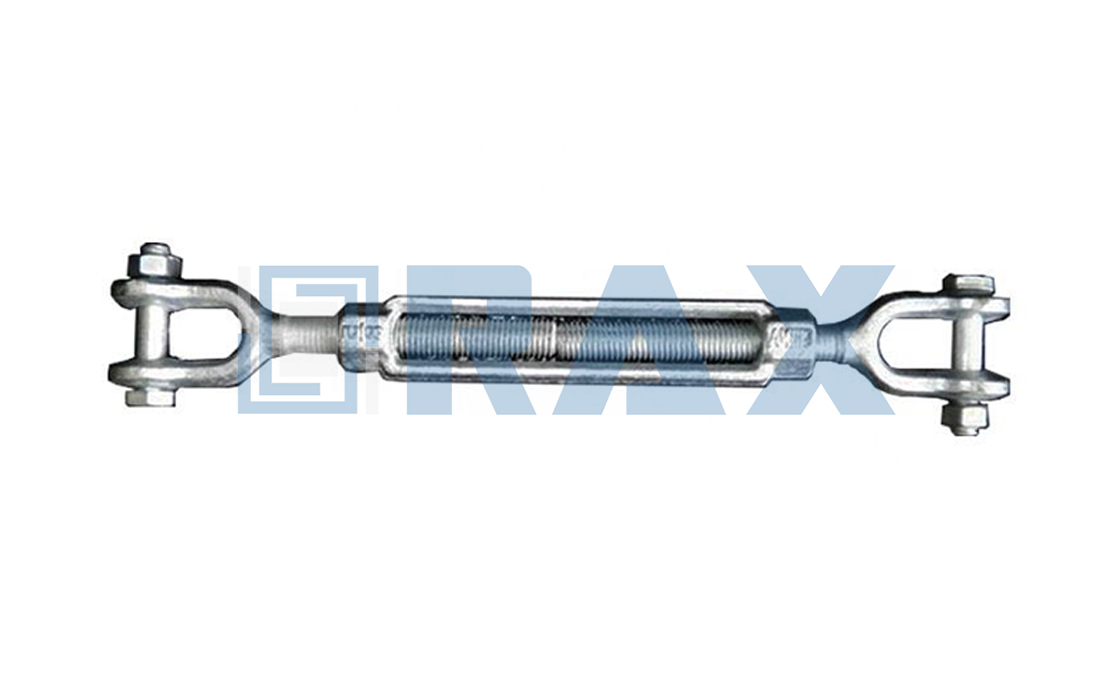

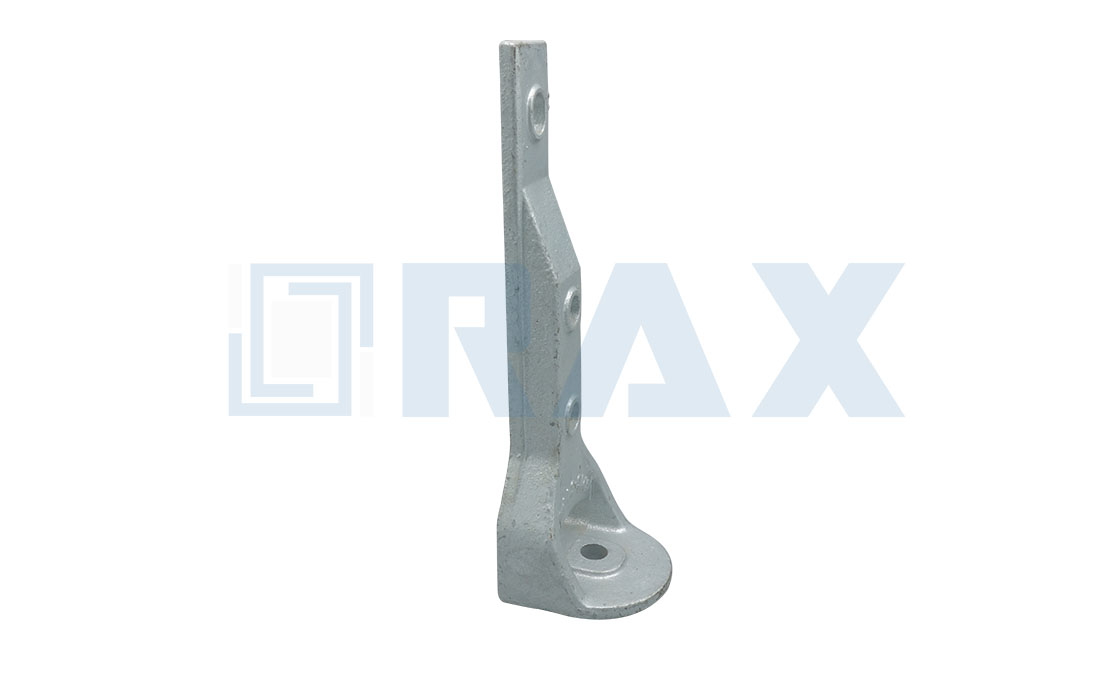

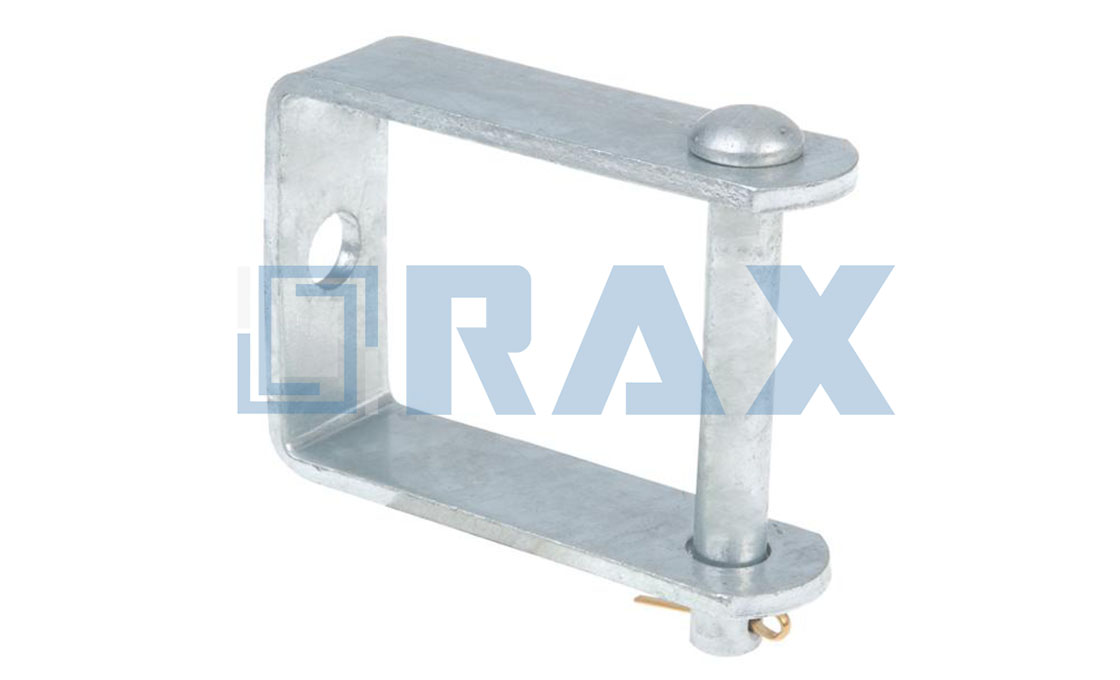

Adjustable Turnbuckle

Turnbuckles, also known as stretching screws, are essential fittings used to adjust the tension or length of ropes, cables, and tie rods. These versatile devices serve as adjustable extension links, ensuring proper tower clearance on assemblies at tower ends. The Turnbuckle is designed for heavy-duty applications and is commonly utilized in conjunction with insulator fittings and conductor hardware. Its robust construction allows for reliable performance in demanding environments.

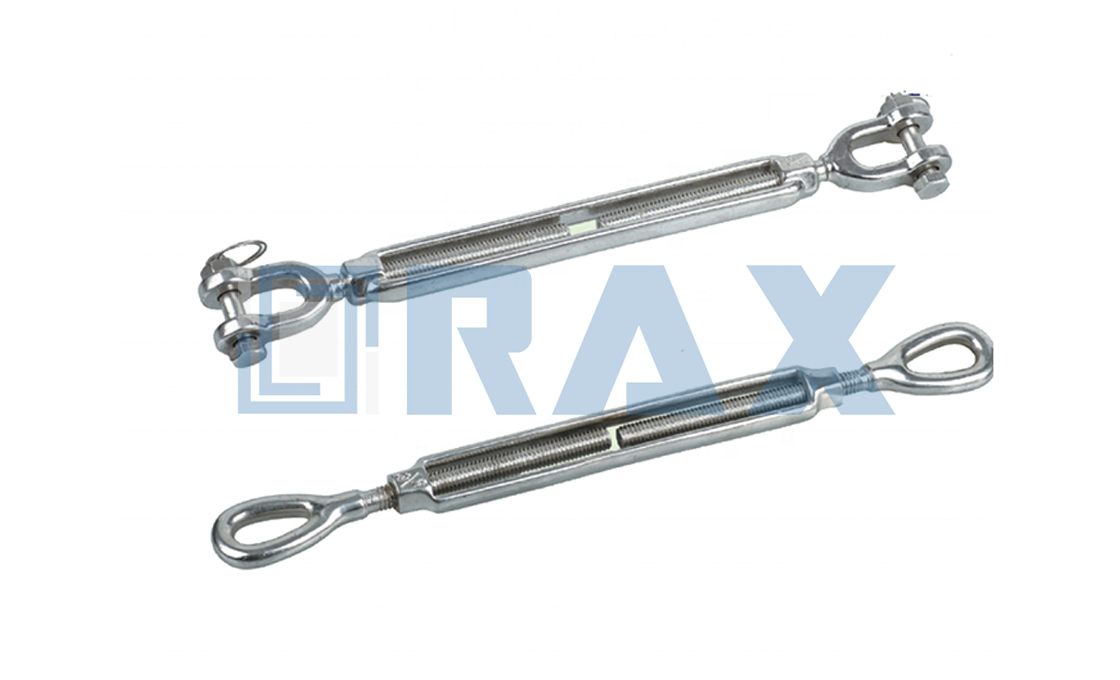

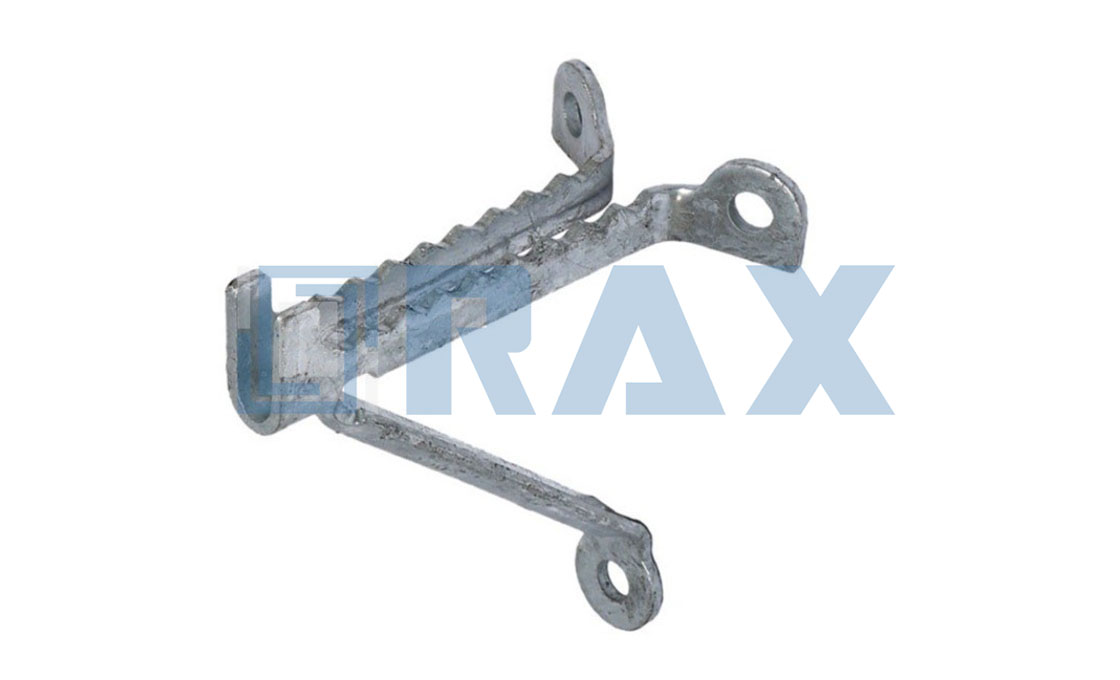

The Turnbuckle mainly comes in 3 types, including eye-eye, jaw-eye, jaw-jaw configurations, each suited for specific applications. For instance, jaw-eye turnbuckles are ideal for connecting cables to structures, while jaw-jaw turnbuckles are used for in-line pulls. This adaptability makes the Turnbuckle a critical component in telecommunications and power distribution systems. It can be customized to meet specific requirements, ensuring compatibility with different structures and load capacities.

Key Features:

• High strength rating up to 26,000 lbs

• Durable galvanized steel construction

• Significant adjustment capabilities

• Supplied with bolts and nuts for easy installation

• Customizable sizes available

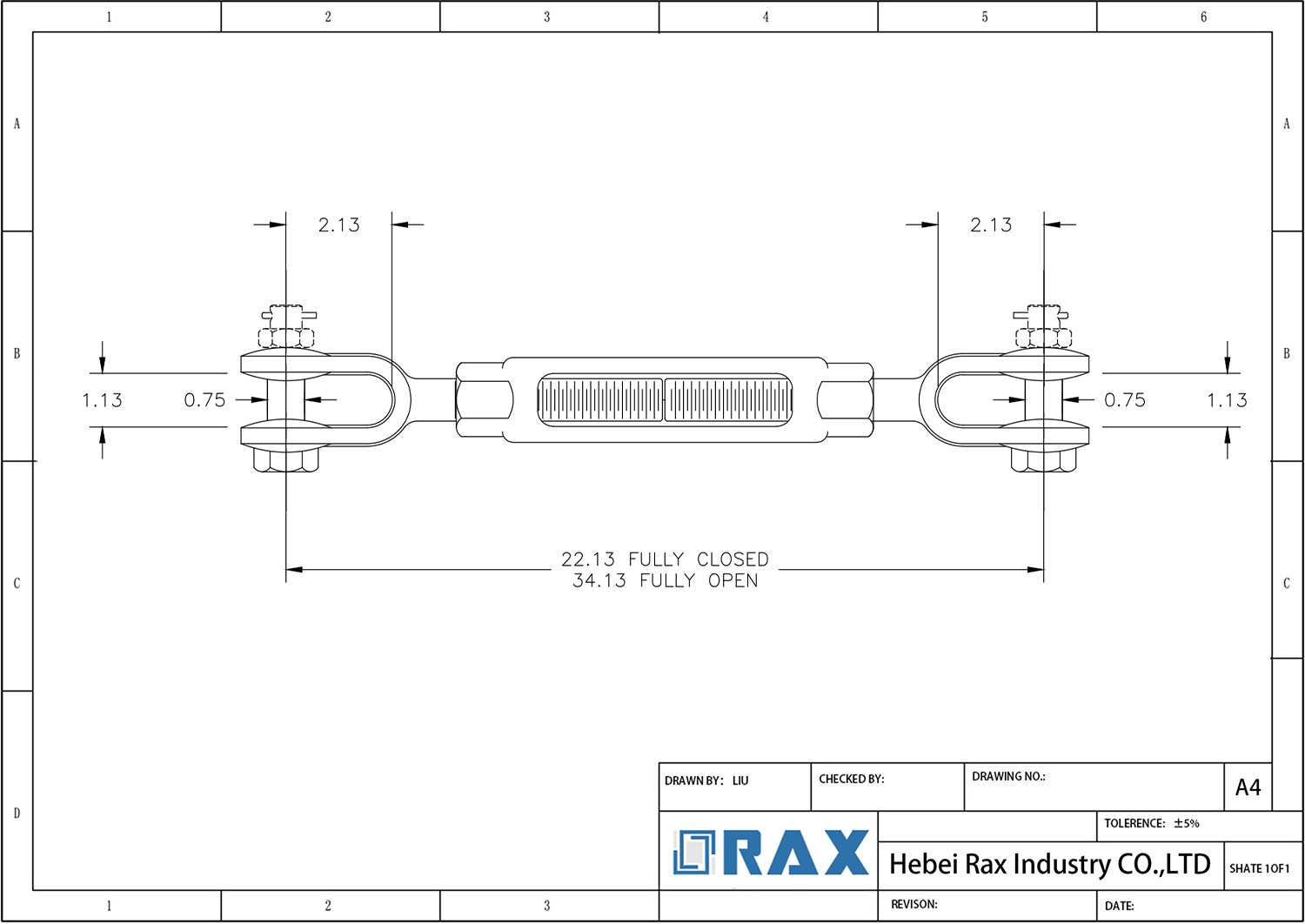

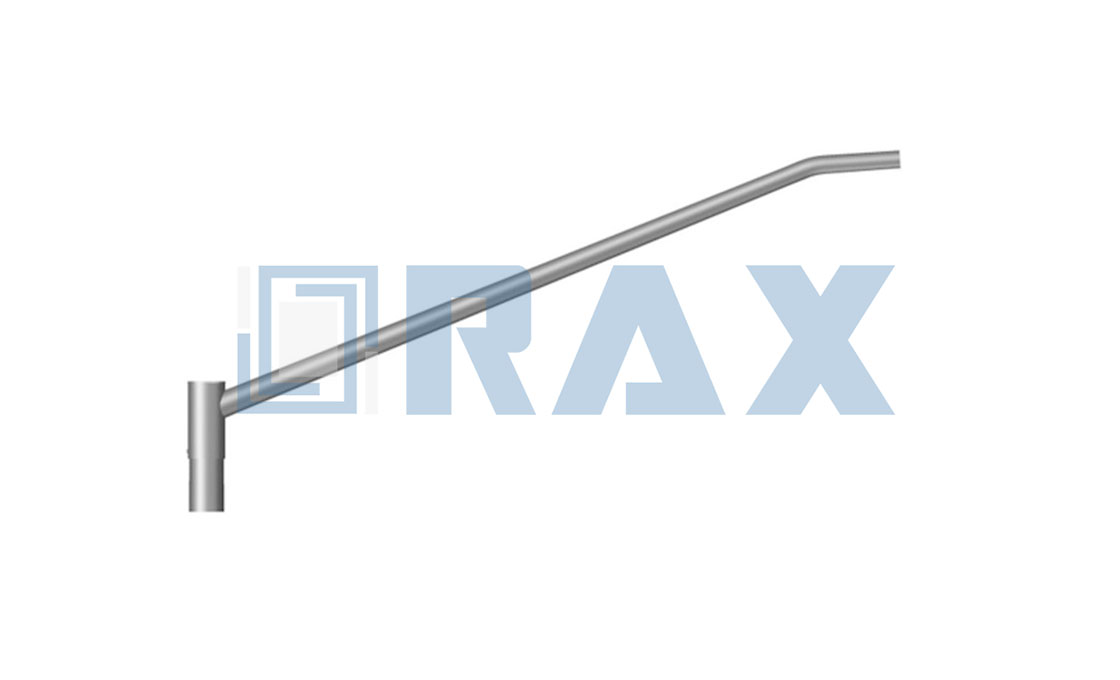

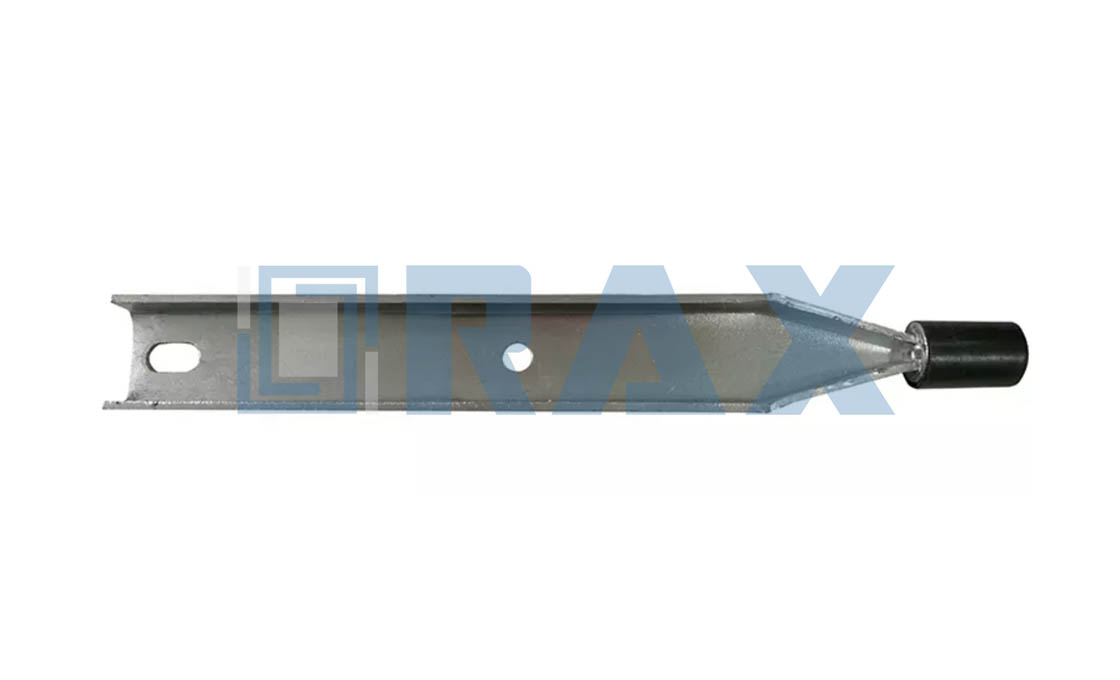

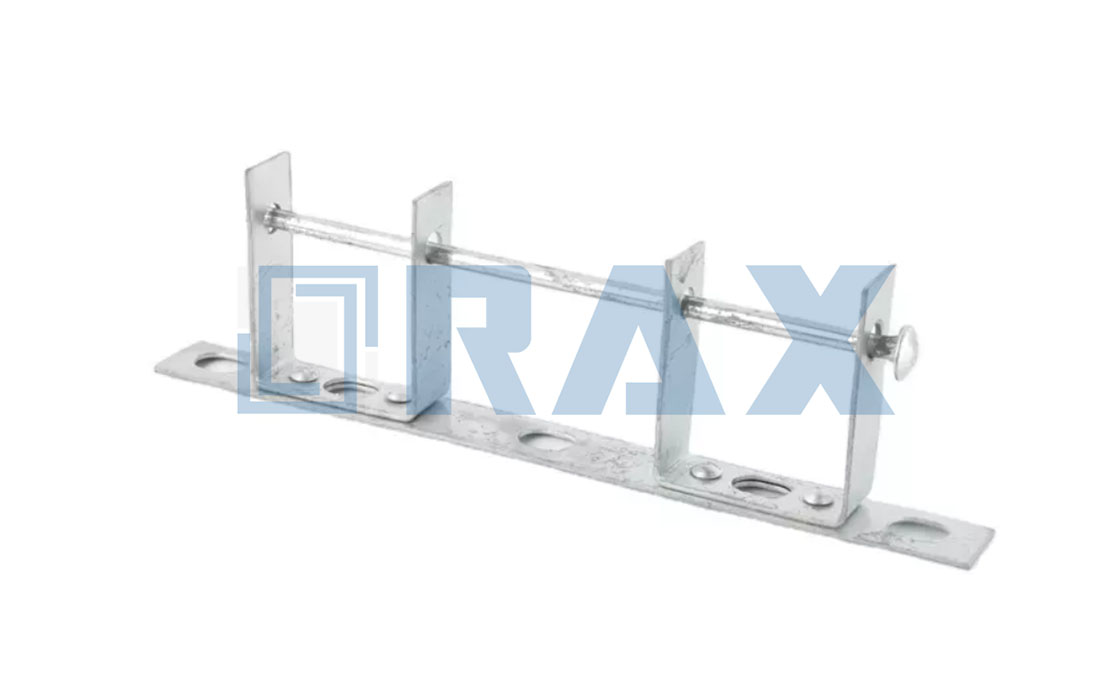

Adjustable Turnbuckle Drawing

Frequently Asked Questions (FAQ)

What is a turnbuckle and how is it used?

What is a turnbuckle and how is it used?

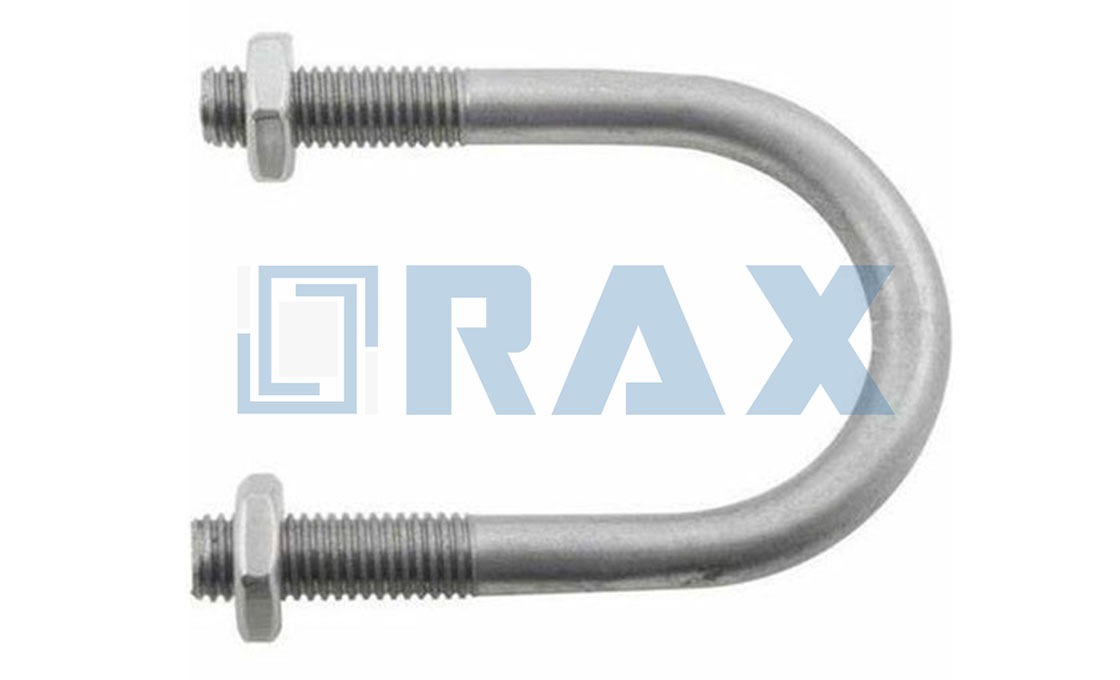

A turnbuckle is an adjustable device used to tighten or loosen cables, ropes, or tie rods. It consists of a metal frame with two threaded ends that can be rotated to adjust tension. Turnbuckles are commonly used in construction and rigging applications to maintain proper tension in structures.

What are the standard sizes of turnbuckles?

Turnbuckles come in various standard sizes, including:

- 5/8″ Jaw-Eye

- 3/4″ Jaw-Jaw

- 1-1/2″ Jaw-Jaw

We are a leading manufacturer capable of customizing turnbuckles according to specific customer requirements.

What materials are turnbuckles made from?

Turnbuckles are typically made from high-strength materials such as forged steel or galvanized steel. These materials provide durability and resistance to corrosion, ensuring longevity in outdoor environments.

How do I determine the load capacity of a turnbuckle?

The load capacity of a turnbuckle is determined by its design and material strength. For example, a 3/4″ Jaw-Jaw turnbuckle can have a breaking strength of up to 26,000 lbs. Always refer to the manufacturer’s specifications for accurate load ratings.

Can turnbuckles be used for both tension and compression?

Yes, turnbuckles can be used for both tension and compression applications. They are versatile devices that allow for adjustments in either direction, making them suitable for various structural needs.

How do I install a turnbuckle?

To install a turnbuckle:

- Attach one end to a fixed point using appropriate hardware.

- Connect the other end to the cable or rod.

- Rotate the turnbuckle body to adjust tension until desired tightness is achieved.

- Ensure all connections are secure before use.

Are there different types of turnbuckles?

Yes, there are 3 types of turnbuckles, including eye-eye, jaw-eye and jaw-jaw configurations. Each type serves specific applications based on connection needs and tension requirements.

What is the maximum adjustment range for typical turnbuckles?

The maximum adjustment range for turnbuckles varies by model but typically ranges from 6 inches to 18 inches, depending on the specific design and application requirements. Always consult product specifications for exact details.

What is a turnbuckle and how is it used?

What is a turnbuckle and how is it used?