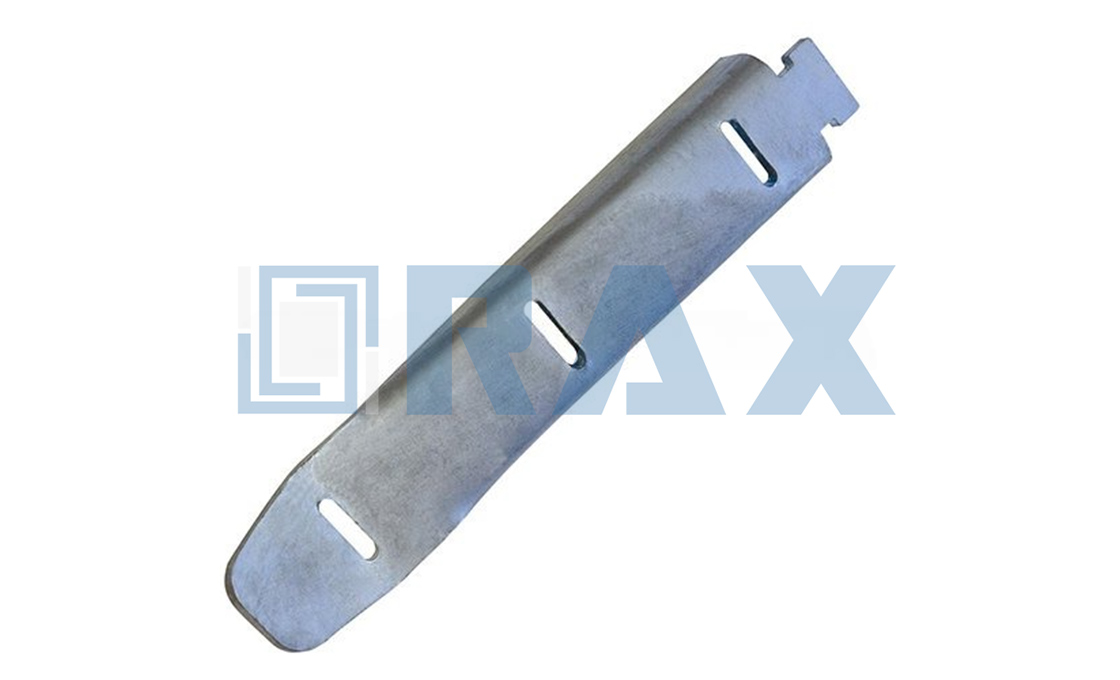

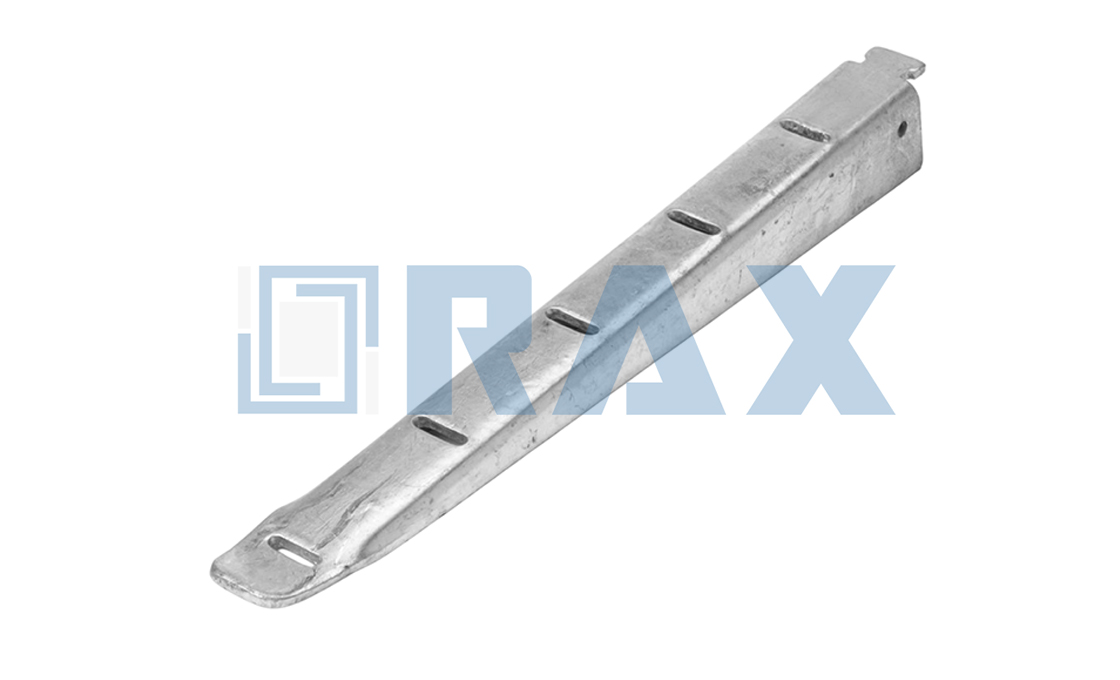

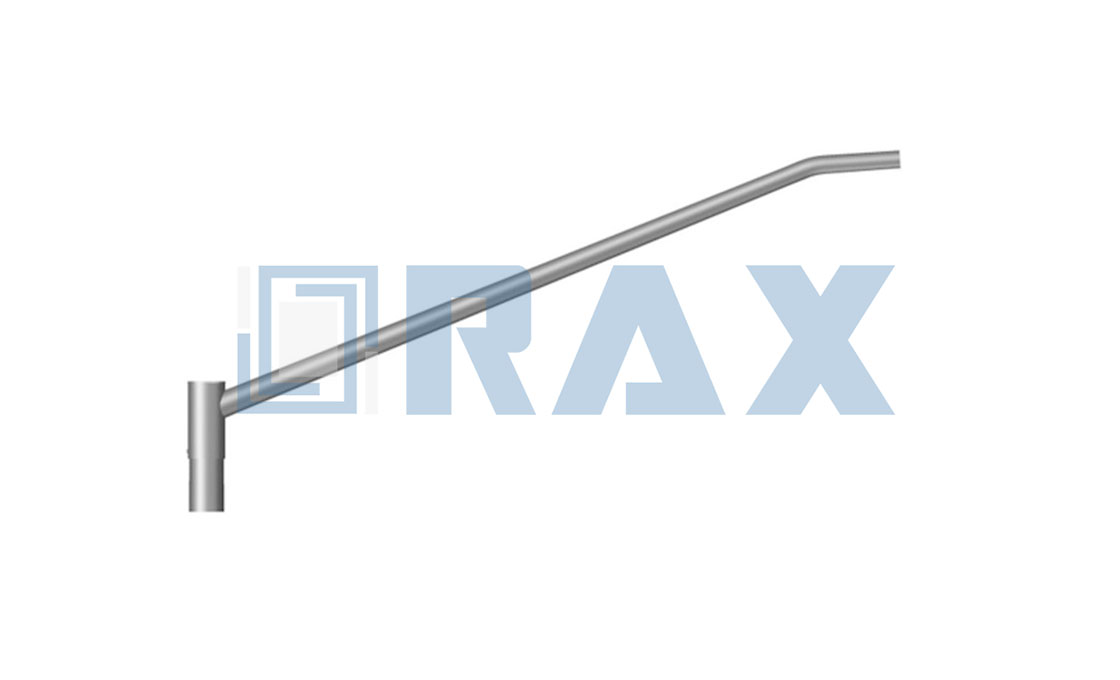

Cable Rack Hook

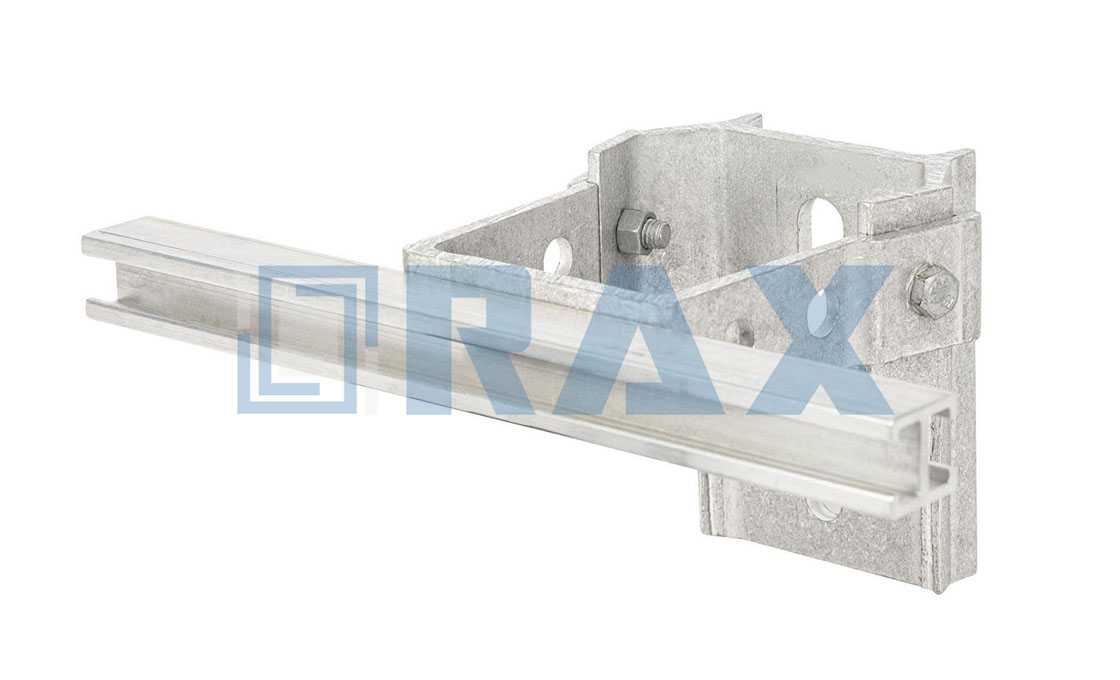

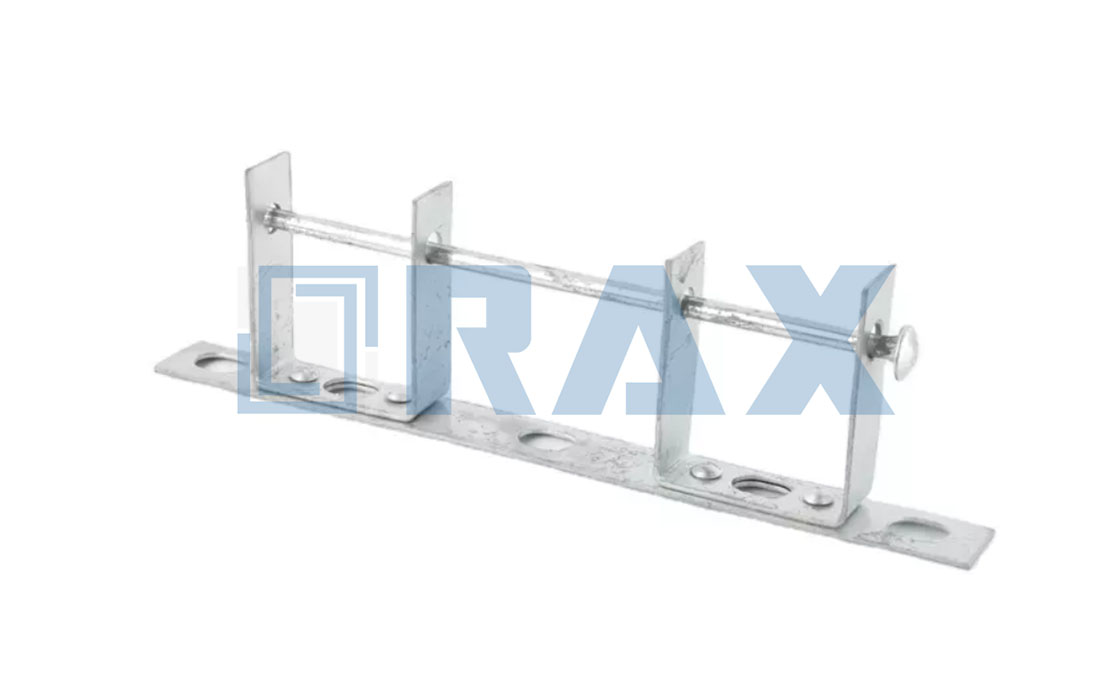

Cable Rack Hooks are essential support components designed for cable management in manholes and underground vaults. They fit snugly into T-slots along cable rack channels, providing secure mounting points. These hooks, also known as Vault Cable Rack Steps, underground cable rack support hooks or stanchions, work with various cable rack systems including T-Slot Channel, T-Section, and Nob-Loc styles.

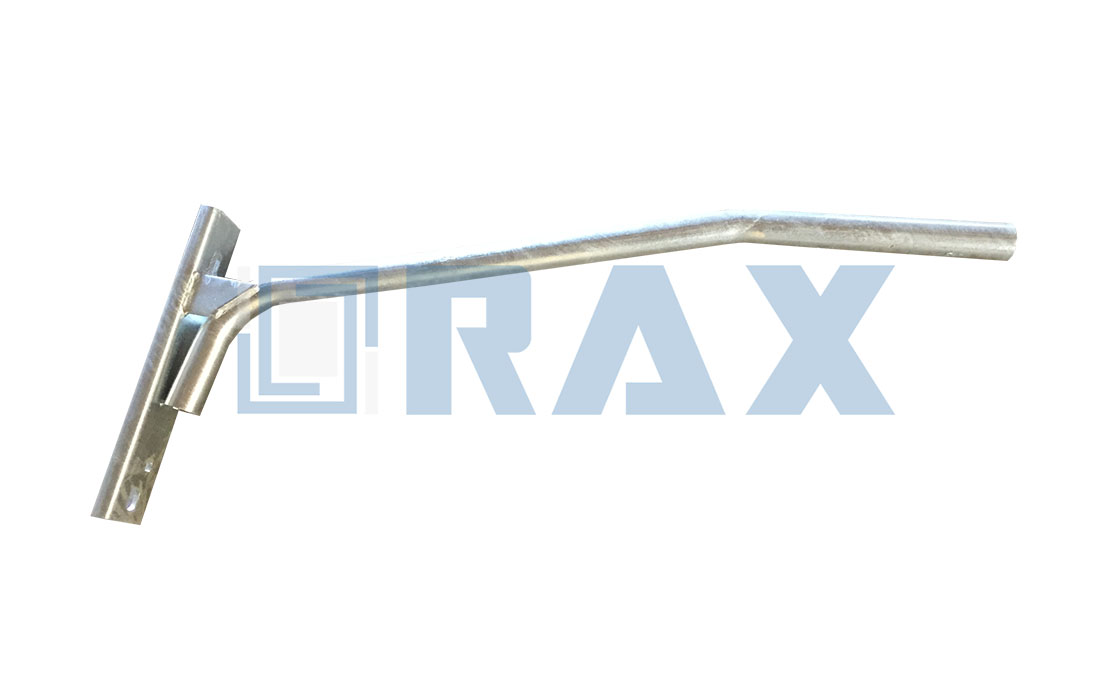

The Cable Rack Hook installation process involves inserting the hook base into rack slots at desired intervals. They feature turned-up ends that prevent cables or rack insulators from slipping off during use. The hooks create an organized shelving system when properly spaced, allowing for efficient cable routing and protection.

Cable Rack Hooks come in multiple lengths ranging from 4 inches to 18 inches to accommodate different vault sizes. They are manufactured from 3/16-inch steel with smooth surfaces to prevent cable damage. The hooks can support loads up to 300 pounds when properly installed, making them suitable for heavy-duty utility applications.

Features:

• Hot-dip galvanized finish provides corrosion resistance for underground environments

• Generous radius design protects cables from bending damage

• Available with optional PVC coating for additional cable protection

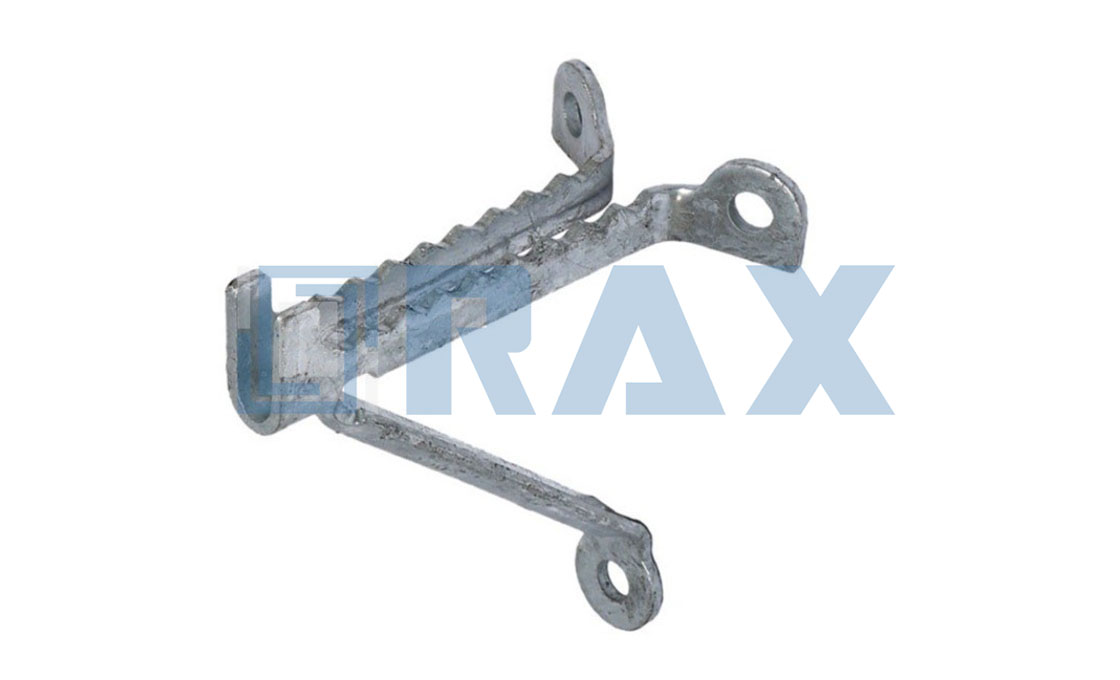

• Locking mechanism ensures secure attachment to rack channels

• Turned-up ends prevent accidental cable displacement

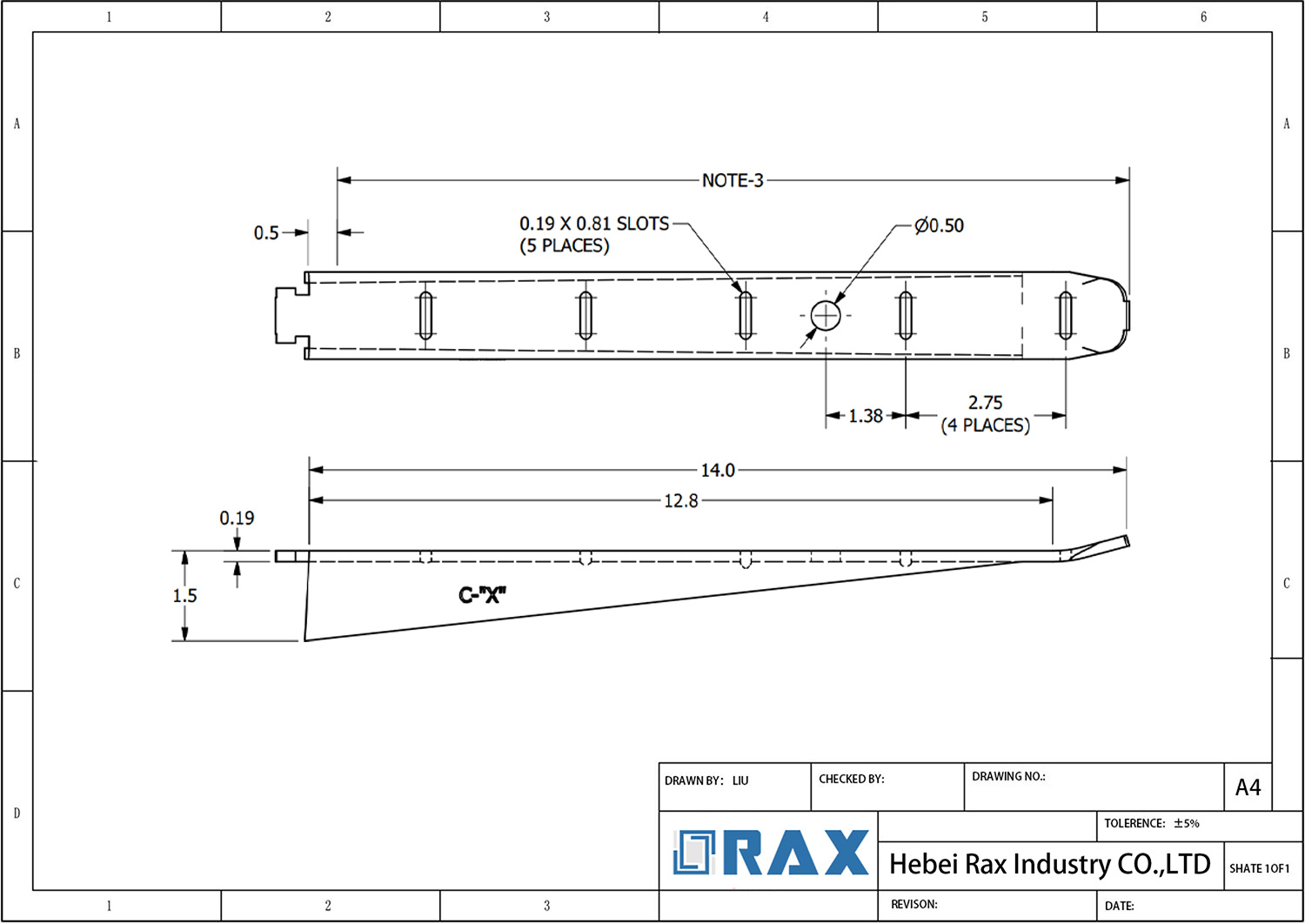

Cable Rack Hook Drawing

Frequently Asked Questions (FAQ)

What are the standard dimensions of underground cable rack hooks?

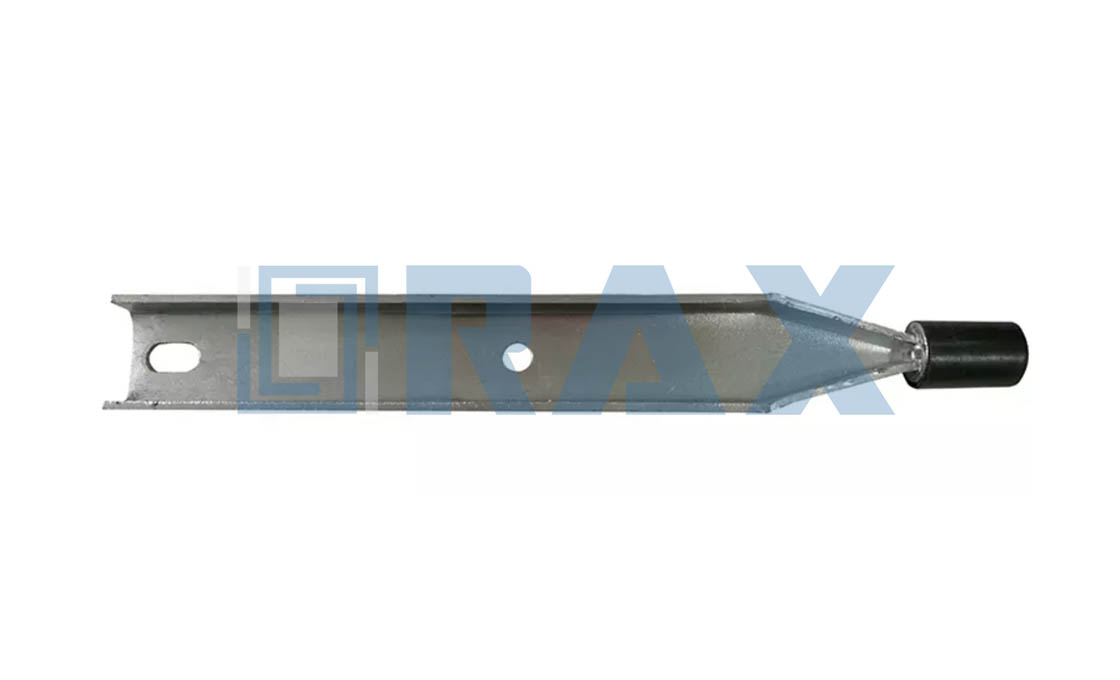

Cable rack hooks are typically made from 3/16-inch steel with varying extension lengths: 4 inches (102mm), 7.5 inches (190mm), 10 inches (254mm), 14 inches (356mm), and 18 inches (457mm). They are designed to fit into T-slots spaced at 1-1/2 inch intervals. More sizes can be customized.

What is the load rating for standard cable rack hooks?

Standard cable rack hooks are load rated to 300 pounds when properly installed in cable racks. The hooks are hot-dip galvanized and feature turned-up ends to prevent cables from slipping off while maintaining their rated load capacity.

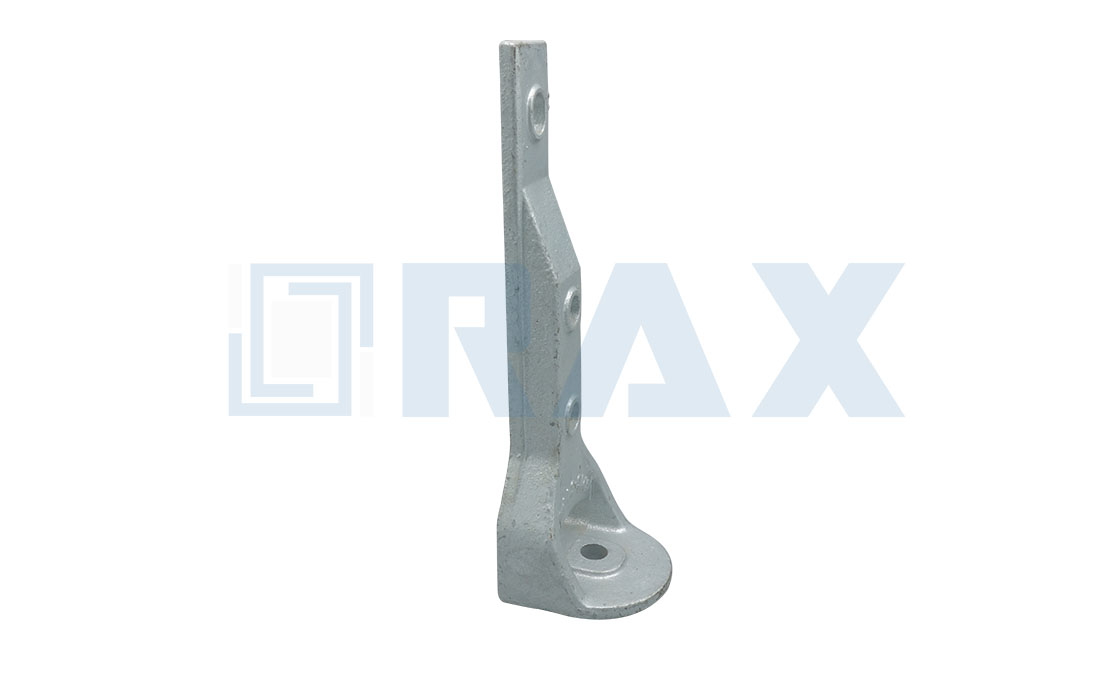

How are cable racks typically mounted in manholes?

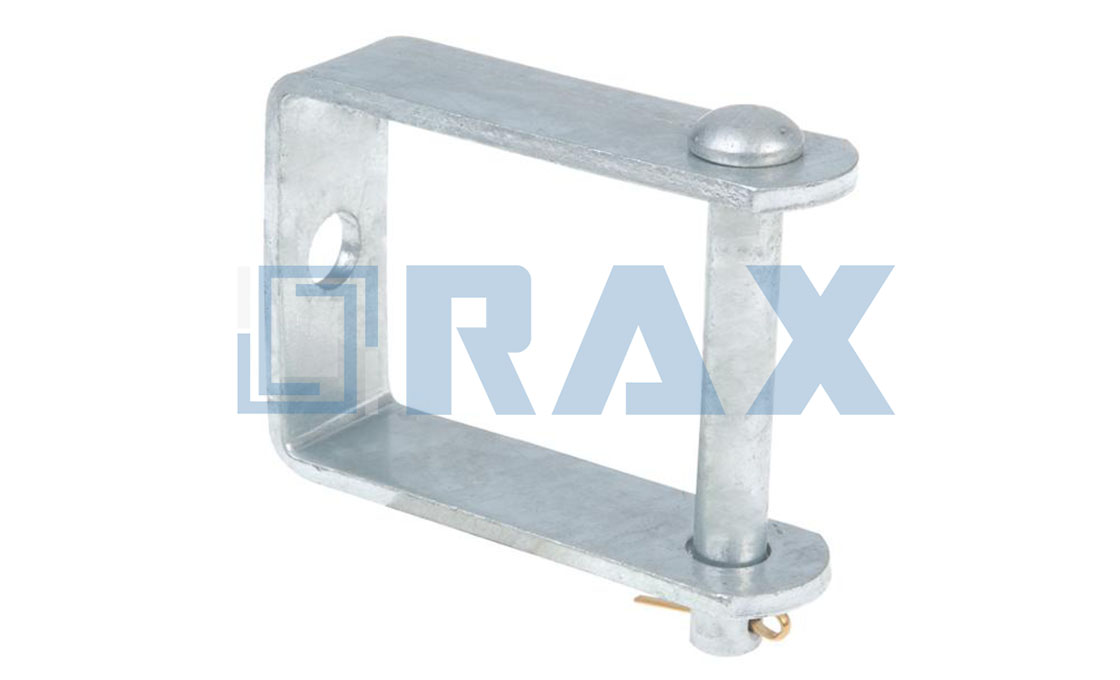

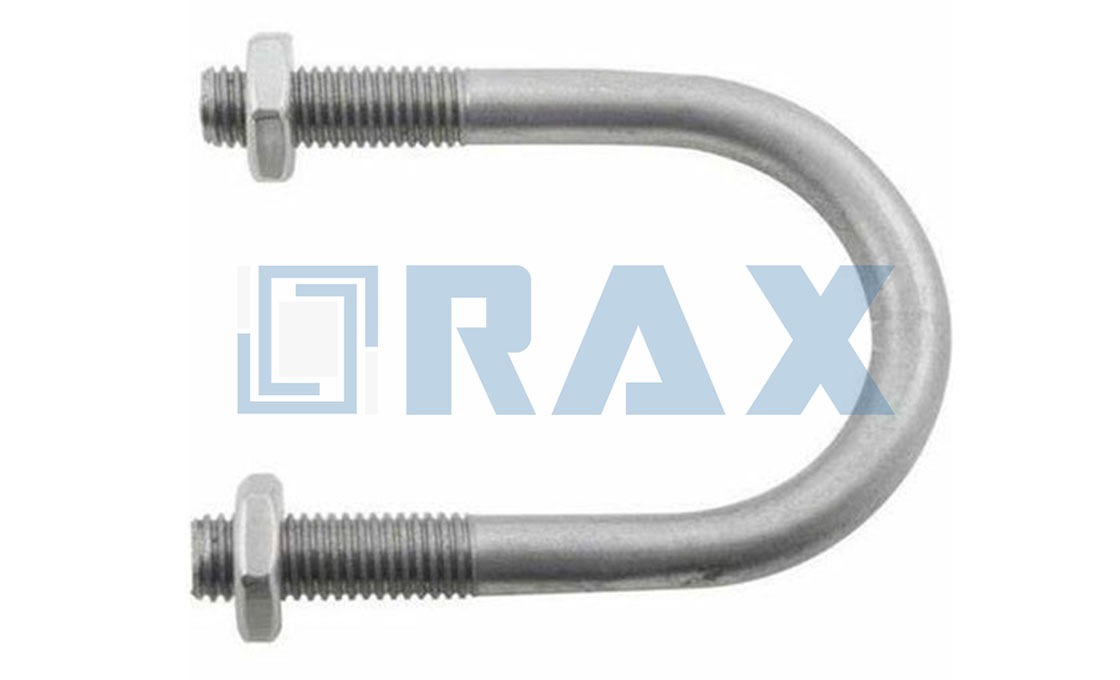

Cable racks with 8, 14, and 18 holes have 19/32″ x 3/4″ mounting slots at each end that interlock, allowing multiple racks to be combined into one unit. Longer racks are mounted through T-slots using 1/2″ or M12 mounting hardware.

What protective features are built into cable rack hooks?

Cable rack hooks feature smooth top surfaces, generous radius bends, and turned-up ends to protect cables from damage. They are hot-dip galvanized for corrosion resistance and can be fitted with porcelain insulators for additional cable protection.

What additional accessories are available for cable rack systems?

Cable rack systems can be equipped with plastic T-slot rack hook clips, porcelain insulators , zinc locking clips, and stainless steel or plastic-coated hook variants for specialized applications.

How are cable racks spaced in manholes and vaults?

Cable racks are typically mounted with bolt hole spacing of 13-1/2 inches for 8-hole racks, 22-1/2 inches for 14-hole racks, and 28-1/2 inches for 18-hole racks, allowing for proper cable support and organization.

What materials are used in cable rack construction?

Cable racks are manufactured from 1-1/2″ x 9/16″ x 3/16″ hot rolled steel channel and undergo hot-dip galvanization per ASTM A123/A153 standards for durability and corrosion resistance in underground environments.