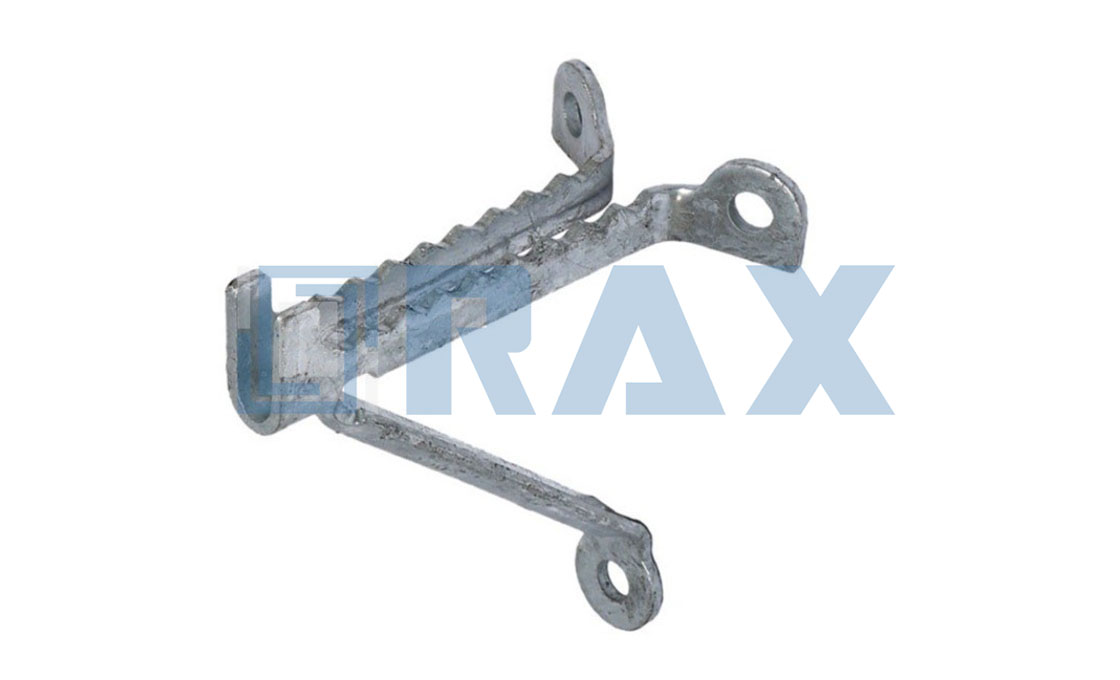

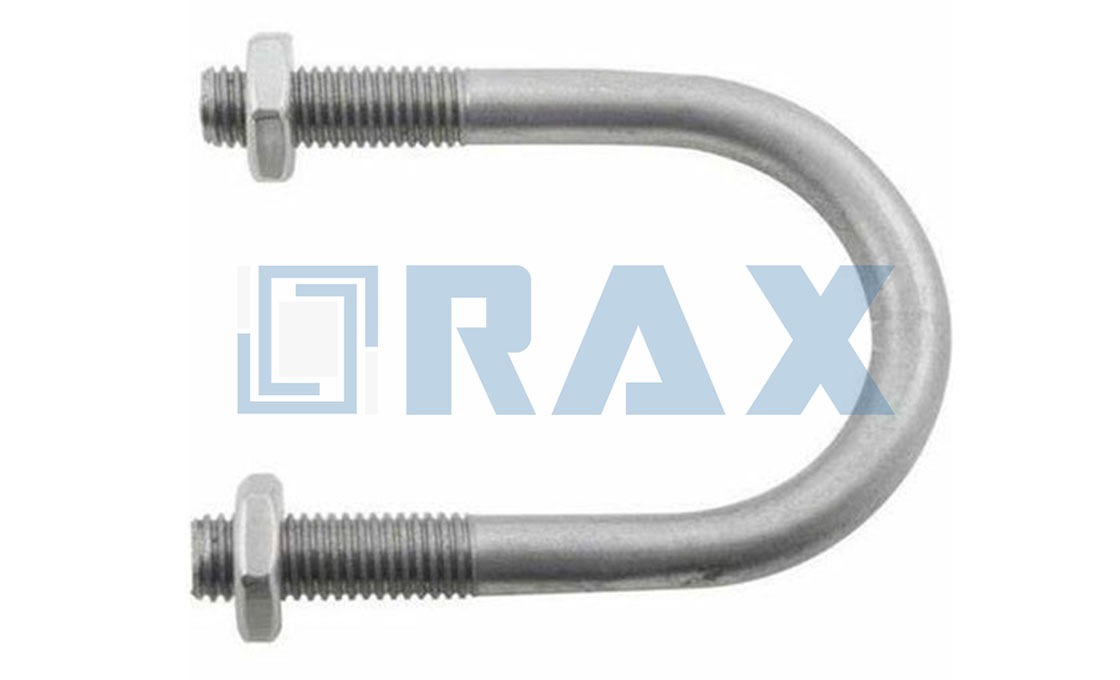

Wire Rope Clip

The Wire Rope Clip consists of three essential components: a U-shaped bolt, forged saddle, and nuts. These versatile fittings create secure eye terminations or join cable ends together with precision. They offer a practical solution for both shop and field installations, providing reliable connections.

Wire Rope Clips come in three main types: drop forged, malleable iron, and fist grip. Drop forged clips feature superior strength due to their linear grain structure from heating and hammering. The clips secure the loose end of wire rope loops, distributing clamping force evenly through the saddle. Their termination efficiency reaches 80% of breaking strength for cables up to 7/8 inch.

Wire Rope Clips require proper installation to maintain maximum working load capacity. The saddle must sit on the load-bearing side to prevent crushing the cable. These clips work best with bare wire rope, as vinyl coatings can reduce holding power. Regular maintenance includes re-tightening nuts to ensure continued secure connections.

Features:

• Multiple size options ranging from 1/16″ to 1-1/4″ for versatile applications

• Available in stainless steel, galvanized, and zinc-plated finishes for corrosion resistance

• Drop forged construction provides superior strength for critical lifting applications

• Simple installation using common hand tools for cost-effective solutions

• Reusable design allows for adjustments and multiple installations

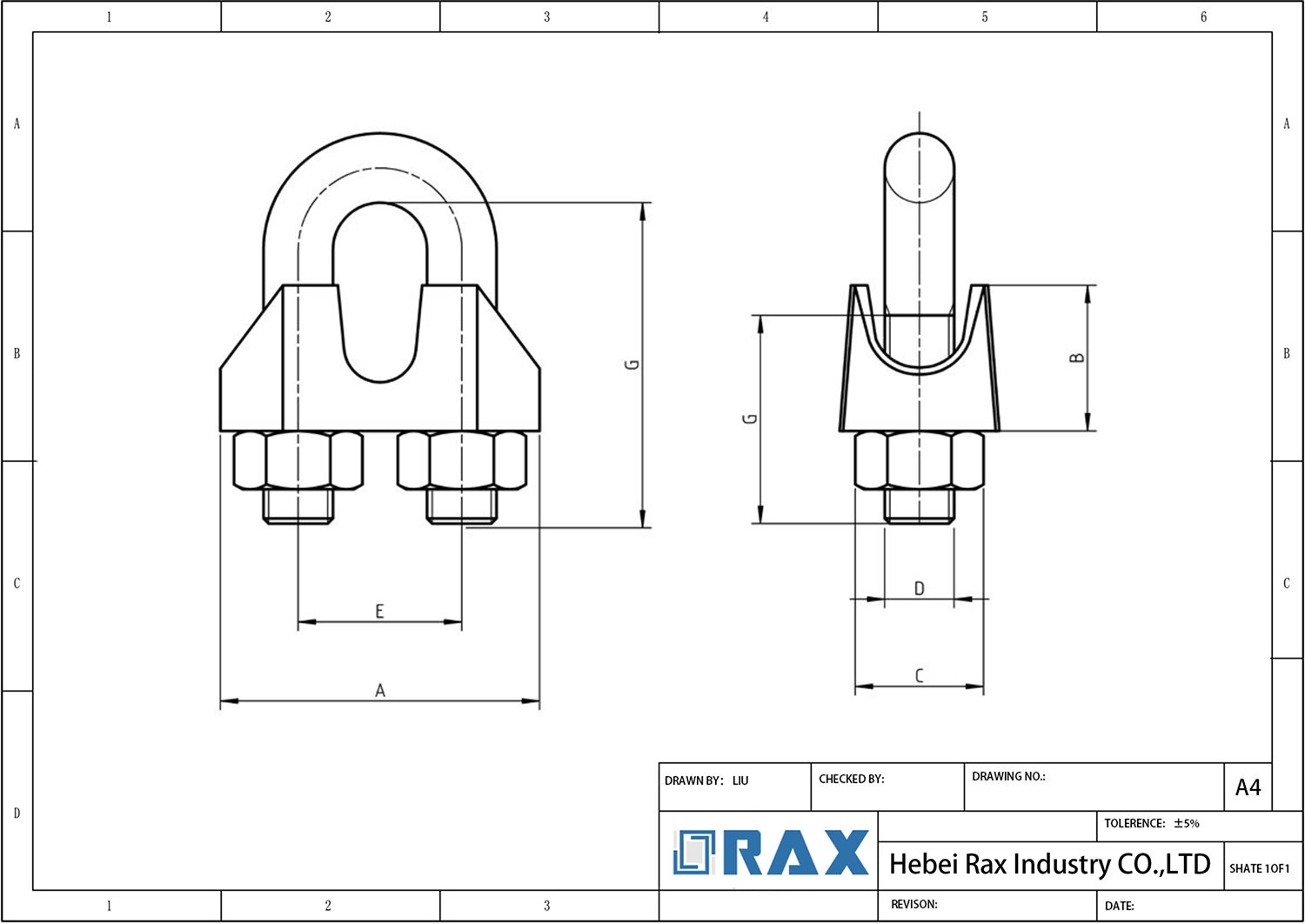

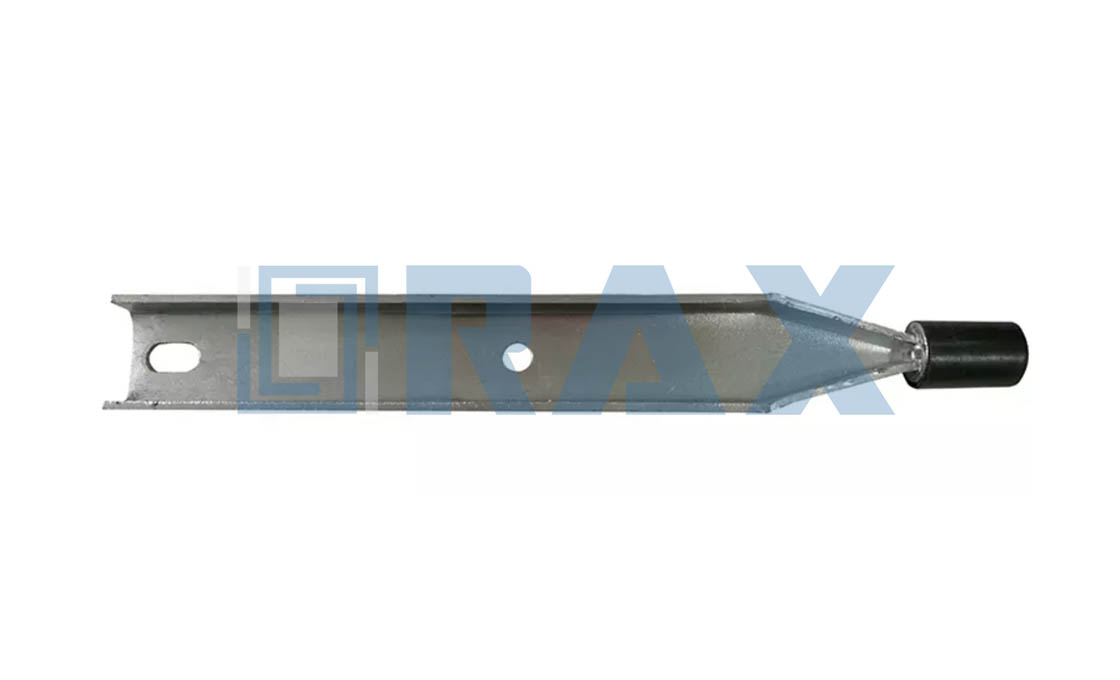

Wire Rope Clip Drawing

| Rope Size (MM) | Size (MM) | KG/PC | ||||||

| A | B | C | D | F | G | |||

| 3 | 9 | 10 | 12 | 4 | 21 | 20 | 0.014 | |

| 5 | 11 | 11 | 13 | 5 | 23 | 24 | 0.015 | |

| 6.5 | 13 | 12 | 15 | 5 | 26 | 28 | 0.021 | |

| 8 | 16 | 14 | 19 | 6 | 28 | 34 | 0.041 | |

| 10 | 19 | 18 | 22 | 8 | 34 | 42 | 0.068 | |

| 11 | 20 | 19 | 22 | 8 | 36 | 54 | 0.072 | |

| 13 | 24 | 23 | 30 | 10 | 42 | 55 | 0.13 | |

| 14 | 25 | 23 | 30 | 10 | 44 | 57 | 0.135 | |

| 16 | 29 | 26 | 33 | 12 | 50 | 63 | 0.21 | |

| 19 | 32 | 29 | 38 | 12 | 54 | 75 | 0.28 | |

| 22 | 37 | 33 | 44 | 14 | 61 | 85 | 0.04 | |

| 26 | 41 | 35 | 45 | 14 | 65 | 95 | 0.44 | |

Frequently Asked Questions (FAQ)

What are the main components of a wire rope clip?

A wire rope clip consists of three essential parts: a U-shaped bolt that wraps around the wire rope, a saddle plate that distributes clamping force, and nuts that secure the assembly by tightening onto the U-bolt ends.

How many clips are needed for a secure connection?

For ropes up to 1/2″ diameter, use at least three clips. For ropes 5/8″ to 7/8″, use four clips. For ropes 1″ to 1-1/4″, use five clips. Clips should be spaced 6-7 rope diameters apart.

What is the termination efficiency of wire rope clips?

Wire rope clip terminations can hold 80% of the wire rope’s breaking strength for cable diameters 1/8″ through 7/8″. For sizes 1″ through 3½”, the termination efficiency increases to 90%.

How should clips be installed with coated cables?

Remove the coating where the clip will be affixed to ensure a secure grip. Select a clip sized for the cable diameter, not the coating diameter. Failure to remove coating can reduce working load limit.

What’s the difference between fist grip and standard U-bolt clips?

Fist grip clips have saddles on both sides of the U-bolt, providing more even force distribution and reducing rope deformation risk. Standard U-bolt clips have a single saddle and are more commonly used.

What’s the proper torque requirement for installation?

Torque requirements vary by rope size: 5/16″ needs 30 ft-lb, 3/8″ needs 45 ft-lb, 7/16″ needs 65 ft-lb, 1/2″ needs 65 ft-lb, 5/8″ needs 95 ft-lb, and 3/4″ needs 130 ft-lb.

What are the consequences of incorrect installation?

Improper installation can reduce the working load limit by up to 40%. The U-bolt must go over the dead end while the saddle must rest on the live end for maximum efficiency.

Can wire rope clips be used for overhead lifting?

Wire rope clips should not be used for making lifting slings or overhead lifting applications. They are designed for less permanent applications like guy lines, support lines, and scaffolding.