Air Flow Spoiler

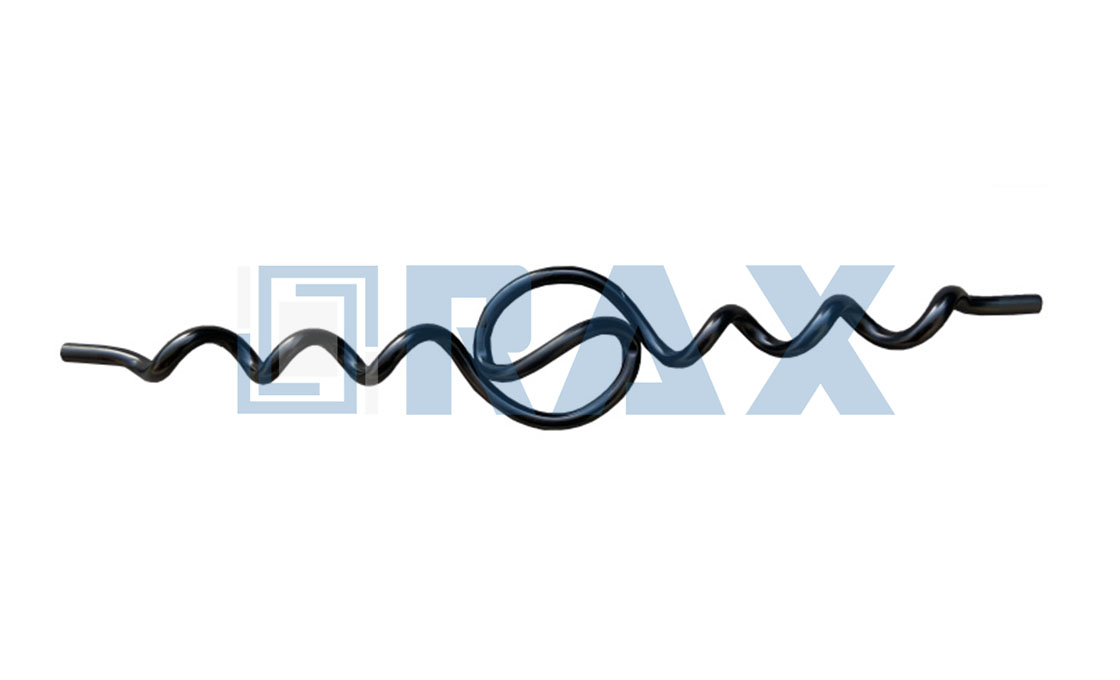

The Air Flow Spoiler is a motion control device designed to suppress galloping in cable spans, preventing severe damage to cable systems. This aerodynamic product features a central spoiling section that disrupts lift by providing a constantly changing profile, along with helical gripping sections on both ends for secure cable attachment. Air Flow Spoilers are available in standard versions for up to 230 kV and EHV versions for up to 345 kV applications.

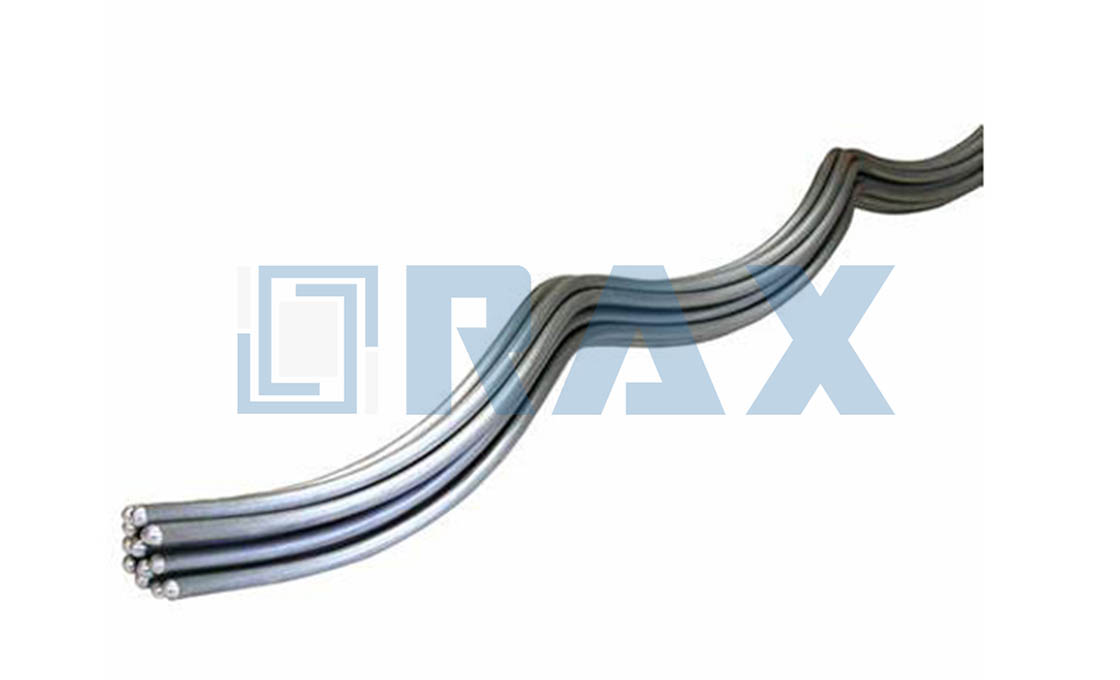

Air Flow Spoilers are used with various cable types, including transmission and distribution lines, ADSS, OPGW, telecommunications cables, and tower down guys. The number and placement of Air Flow Spoilers in each cable span are determined by specialized software based on field and laboratory research. These devices effectively increase cable longevity by mitigating the effects of galloping, a potentially damaging oscillation in overhead power lines.

Features of Air Flow Spoilers:

• Made of durable, UV-rated PVC material

• EHV versions include a co-extruded semi-conductive layer

• Minimizes radio interference in high-voltage applications

• Customizable placement for optimal performance

• Compatible with various cable types and voltages

• Increases cable system reliability and longevity

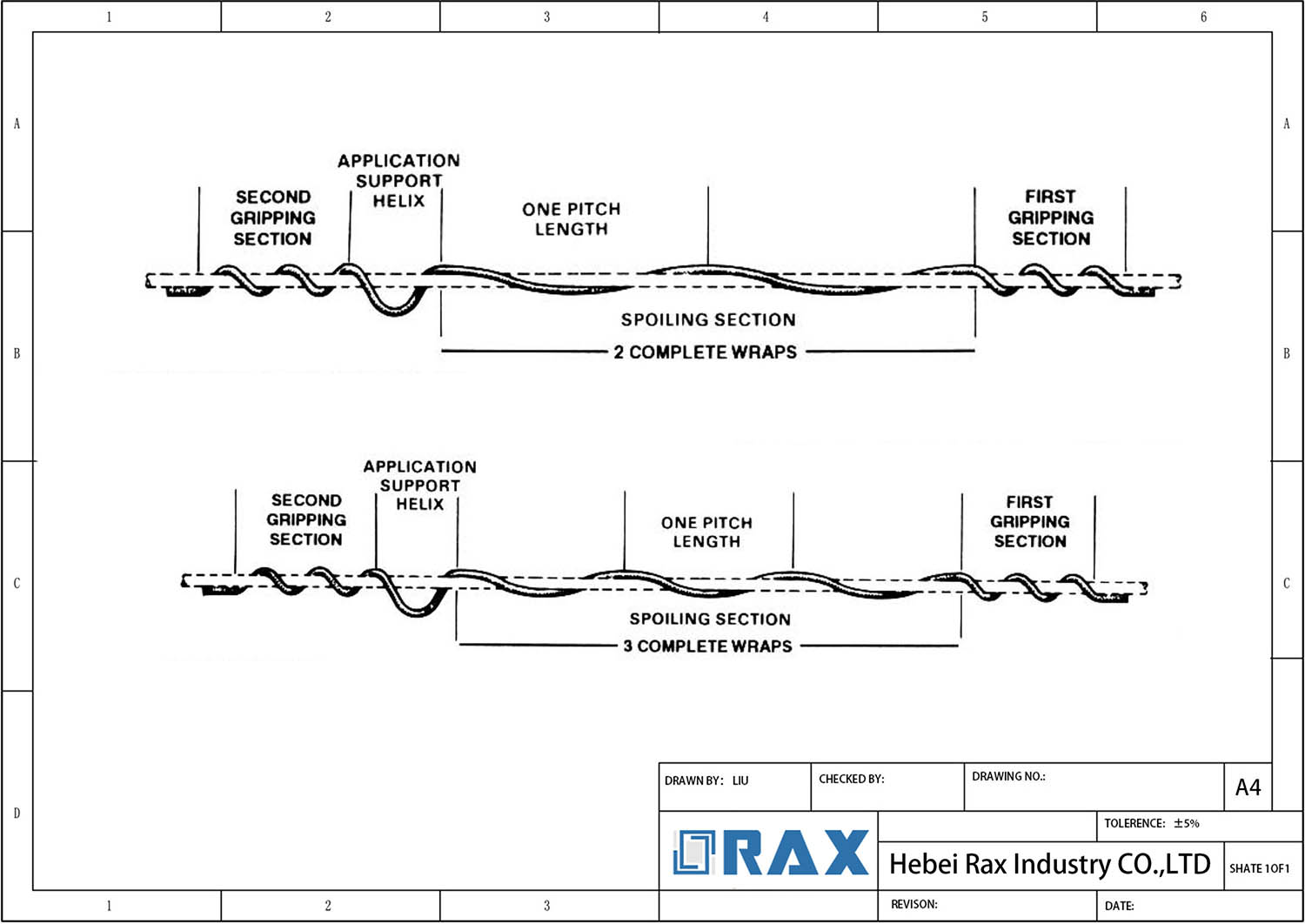

Air Flow Spoiler Drawing

| Span Length in feet | Air Flow Spoilers per cable | Air Flow Spoiler placements start from first structure. | ||

| Distances are measured from same end of Air Flow Spoiler accumulated distances in () | ||||

| 100-130 | 2 | 33.3(33 3) | 28.8(62 0) | 48.0(110.0) |

| 130-160 | 3 | 33.9(33 9) 48.6(140.0) | 28 8(62.6) | 28 8(91.4) |

| 160-190 | 3 | 48.9(48.9) 63.6(170.0) | 28.8(77 6) | 28 8(106.4) |

| 190-220 | 4 | 44 5(44.5) 28 8(130.8) | 28.8(73.3) | 28 8(102.0) |

Frequently Asked Questions (FAQ)

What is an Air Flow Spoiler?

What is an Air Flow Spoiler?

An Air Flow Spoiler is a motion control device made of rigid non-metallic, non-corrosive thermal plastic that wraps around power lines to prevent galloping. It works by disrupting aerodynamic lift forces and providing a constantly changing profile to wind flow.

How does an Air Flow Spoiler prevent line galloping?

The spoiler’s central section maintains aerodynamic stability by creating a continuously changing profile against the wind, while helical gripping sections secure it to the cable. This design disrupts the formation of ice-induced aerodynamic lift that causes line galloping.

What voltage ratings are available for Air Flow Spoilers?

Air Flow Spoilers come in standard versions for up to 230 kV applications and EHV versions for up to 345 kV. The EHV models feature a co-extruded semi-conductive material layer that minimizes radio interference and resists high electrical gradients.

How many Air Flow Spoilers are needed per span?

Multiple spoilers are required per span, typically covering 25% of the span length. For example, a 600-foot span would need 13 Air Flow Spoilers, grouped in the middle 50% of the span with spaces between adjacent units.

What are the temperature limitations for Air Flow Spoilers?

Air Flow Spoilers are rated for continuous operation at temperatures up to 125°C. High-temperature versions are available for specific applications requiring enhanced thermal performance.

How are Air Flow Spoilers installed on power lines?

Installation requires proper placement with support helix on one end to prevent sagging while the gripping section is applied on the opposite end. The spoilers range from 14 to 16 feet in length and are installed with specific spacing.

Where are Air Flow Spoilers most commonly used?

They are primarily used on transmission lines, distribution lines, fiber networks, and telecommunications cables. They’re especially crucial in areas prone to high winds and ice formation, particularly on east-west running lines.

What is an Air Flow Spoiler?

What is an Air Flow Spoiler?