Lashing Wire Clamp

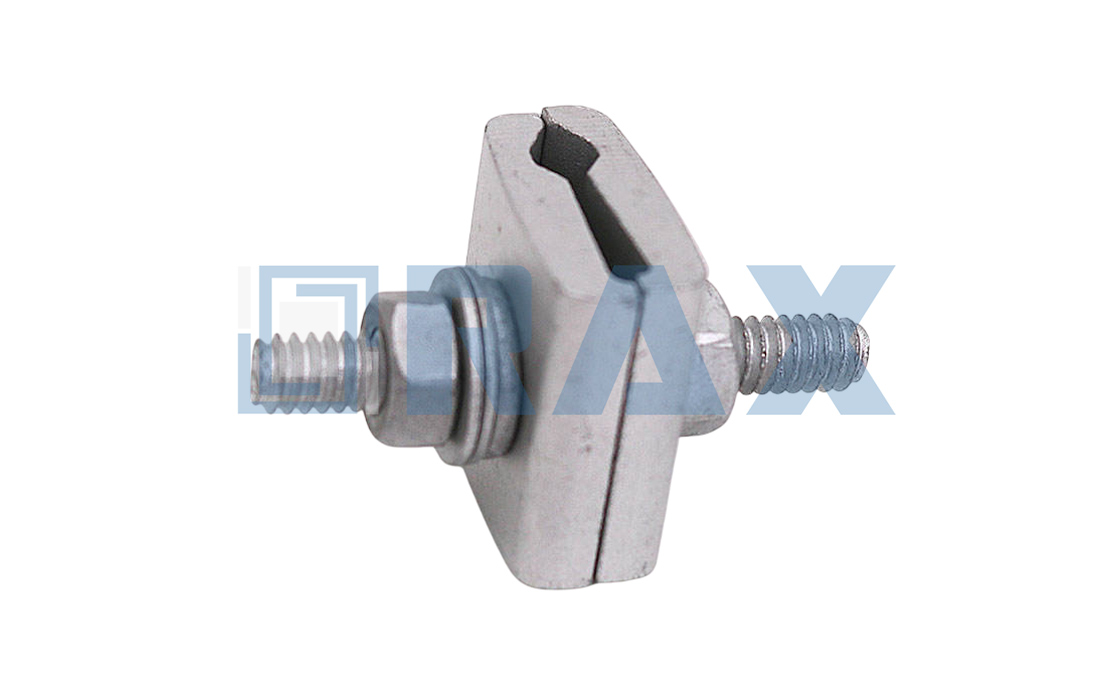

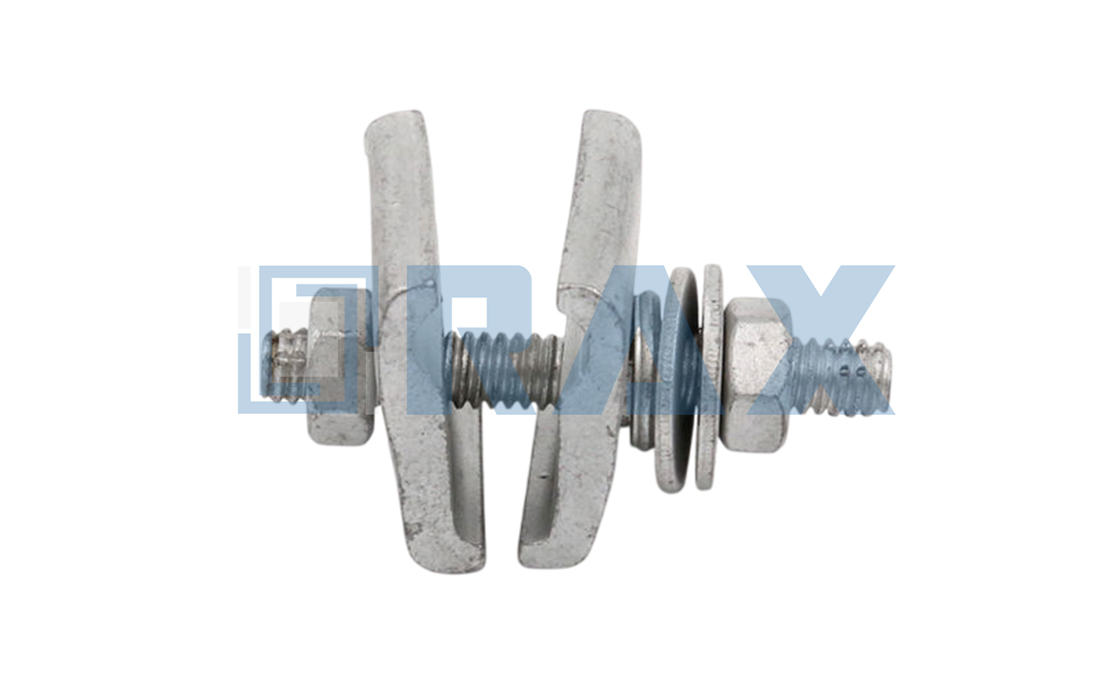

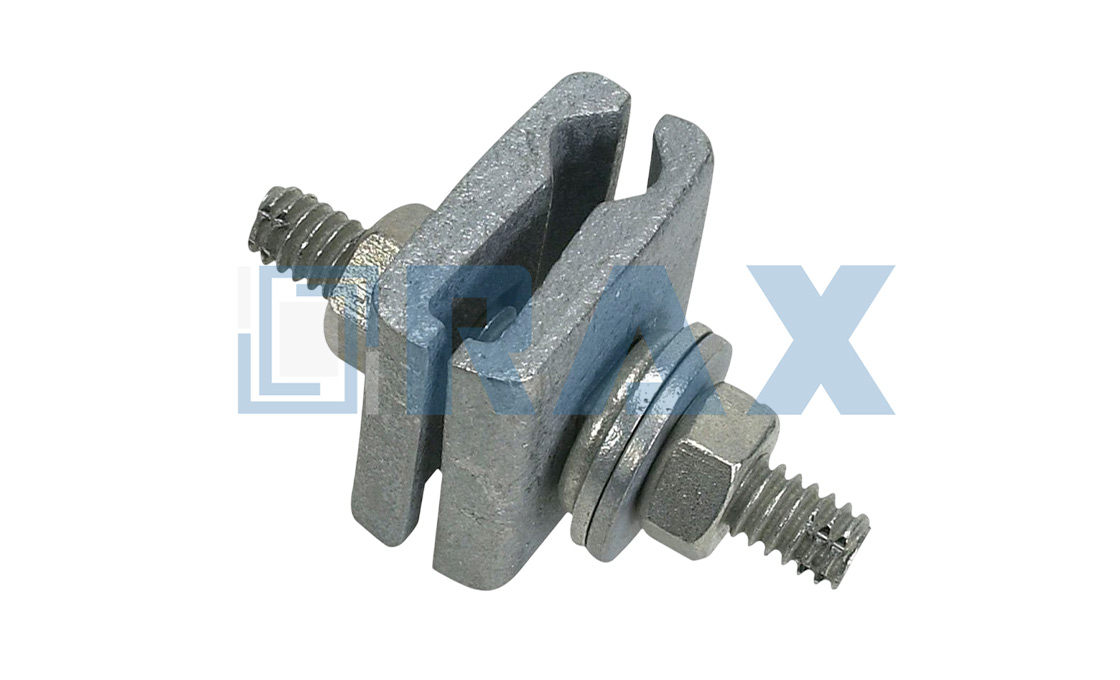

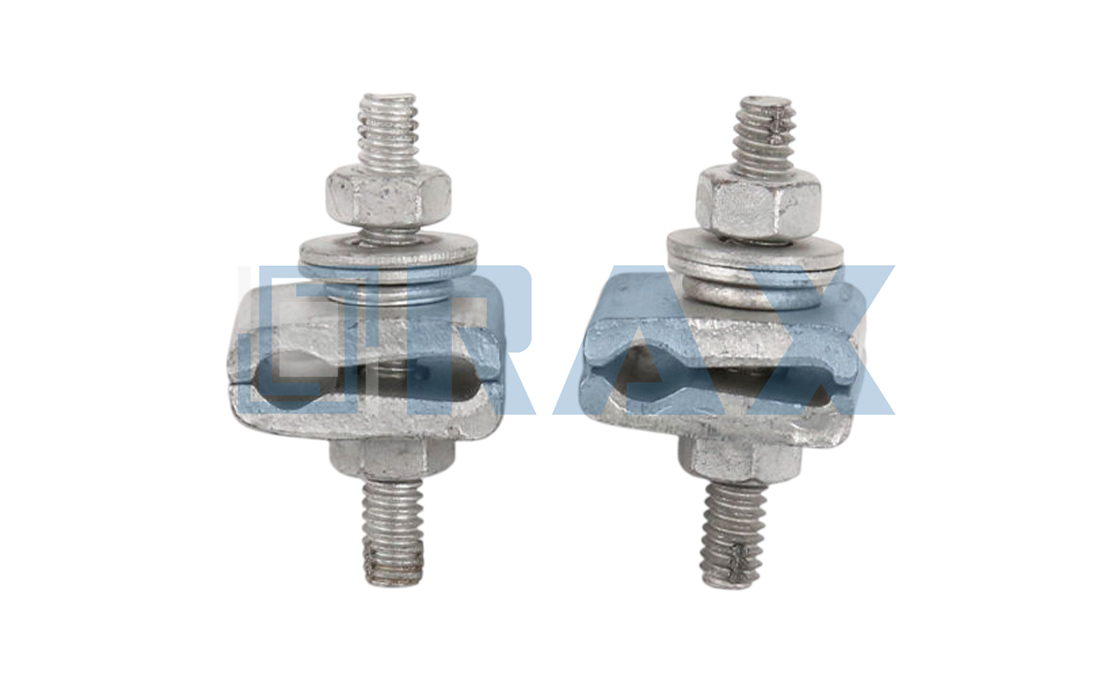

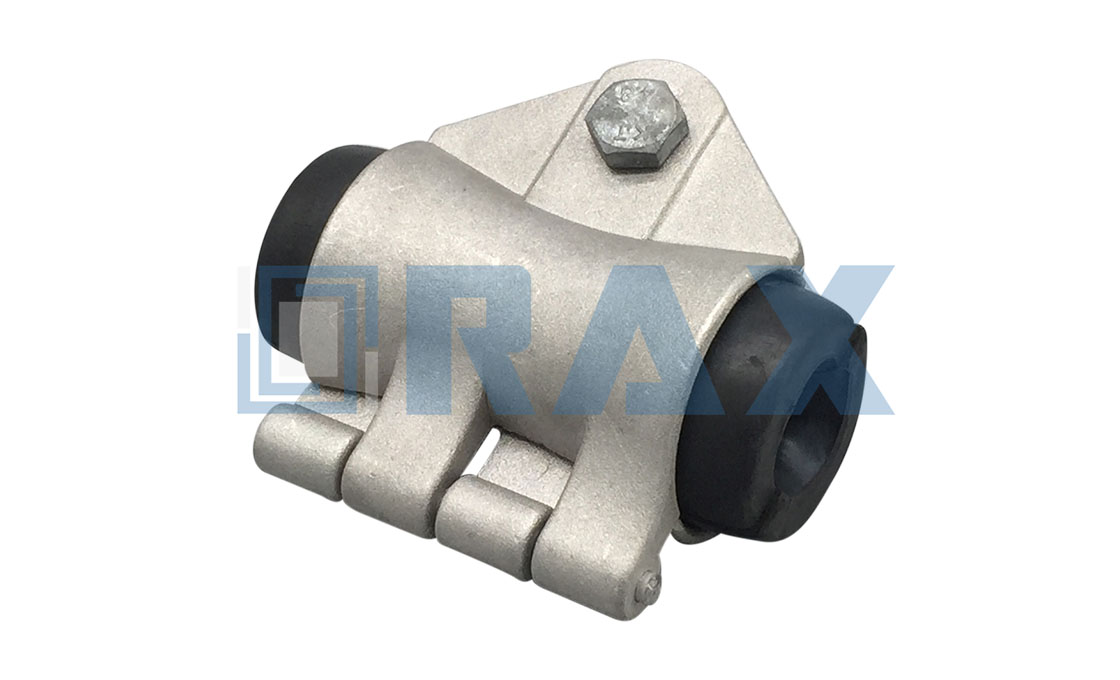

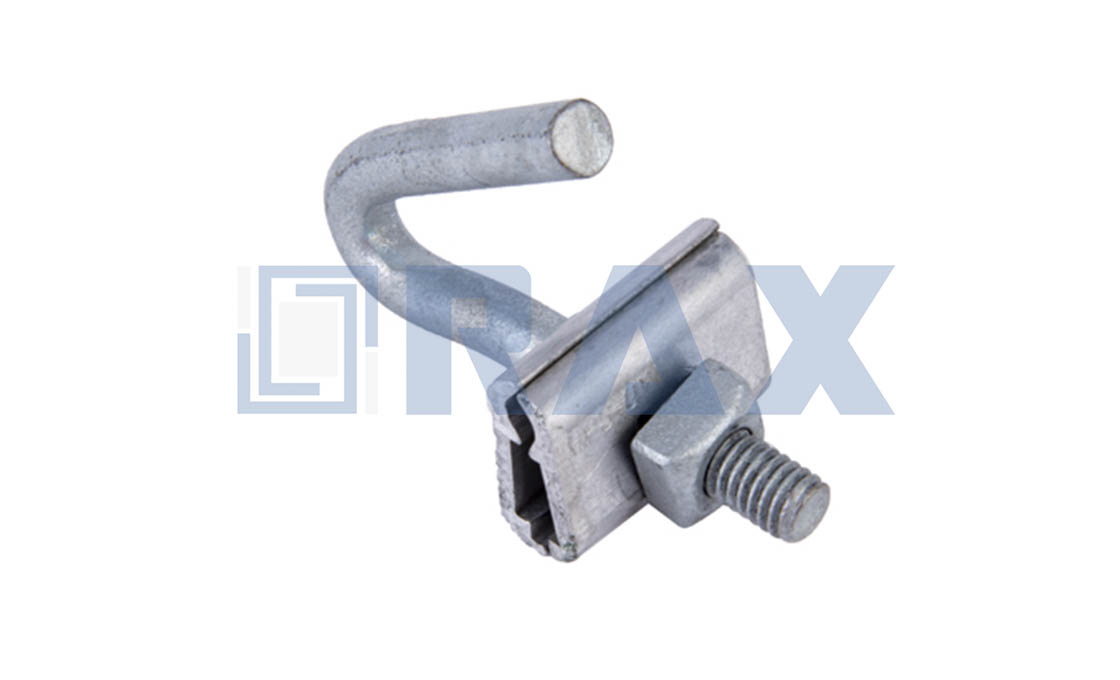

A lashing wire clamp, also known as a cable lashing clamp, is a device used in aerial construction to secure lashing wire terminations or ground wire to a strand. The structure consists of a stud, two washers, and two bug nuts made from stainless steel. There are two main types: D lashing wire clamp and E lashing wire clamp, with the E type featuring a one-piece stamping for permanent wire terminations.

Lashing wire clamps are essential for securing wire terminations in overhead line installations. The clamp can attach to strands ranging from 1/4 inch to 7/16 inch in diameter, with an oversized version available for 3/8 to 9/16 inch strands. To install a lashing wire clamp, place the groove over the wire, follow the strand lay, thread it through, and tighten the terminating nut. The free end must be tucked into the clamp to prevent injury.

Key Features:

– Tensile strength of jaws exceeds 50,000 PSI

– Mechanically galvanized finish for corrosion resistance

– Two grooved plates with threaded stud and flanged shoulder

– Compatible with 6mm to 11mm diameter strands

– Prevents wire breakage and maintains connection integrity

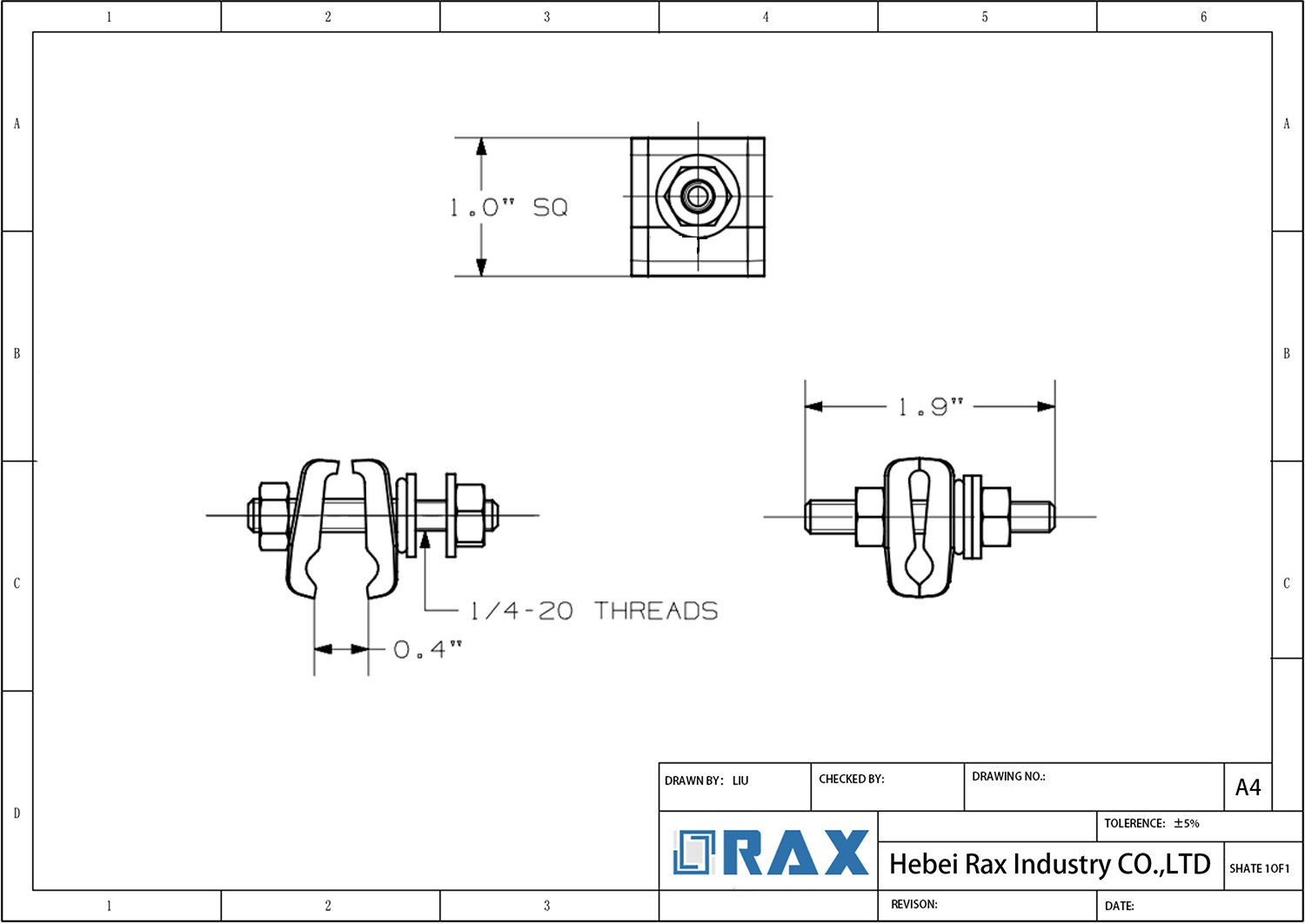

Lashing Wire Clamp Drawing

Frequently Asked Questions (FAQ)

What is a D Cable Lashing Clamp?

What is a D Cable Lashing Clamp?

A D Cable Lashing Clamp is a specialized two-piece metal clamp consisting of a main body and locking bar, used to secure and terminate lashing wires to messenger strands in aerial cable installations. It works with strand sizes from 1/4 to 7/16 inches (6-11mm) diameter.

How do you install a D Lashing Wire Clamp?

Place the clamp over the cable, slide the locking bar over the main body, and press down the pin to secure. The two grooved plates fit on opposite sides of the strand. Use the long-end nut to tighten the clamp and the short-end nut to terminate the wire.

What are the key benefits of D Lashing Wire Clamps?

D Lashing Wire Clamps provide secure temporary and permanent terminations, work in both indoor and outdoor settings, offer corrosion resistance through mechanical galvanized finish, and are more cost-effective than traditional cable lashing methods.

What’s the difference between D and E Lashing Wire Clamps?

While both have similar hardware and clamping ranges, E Lashing Wire Clamps feature a one-piece stamping formed design for perfect messenger alignment, whereas D Clamps use two separate pieces. E Clamps are specifically designed for permanent wire terminations.

How far should the cable guide be kept from the lasher?

The cable guide should be maintained 4 feet in front of the lasher using a stiff rod. The cable reel must be positioned at least 50 feet ahead of the cable guide to ensure proper installation.

What is a D Cable Lashing Clamp?

What is a D Cable Lashing Clamp?