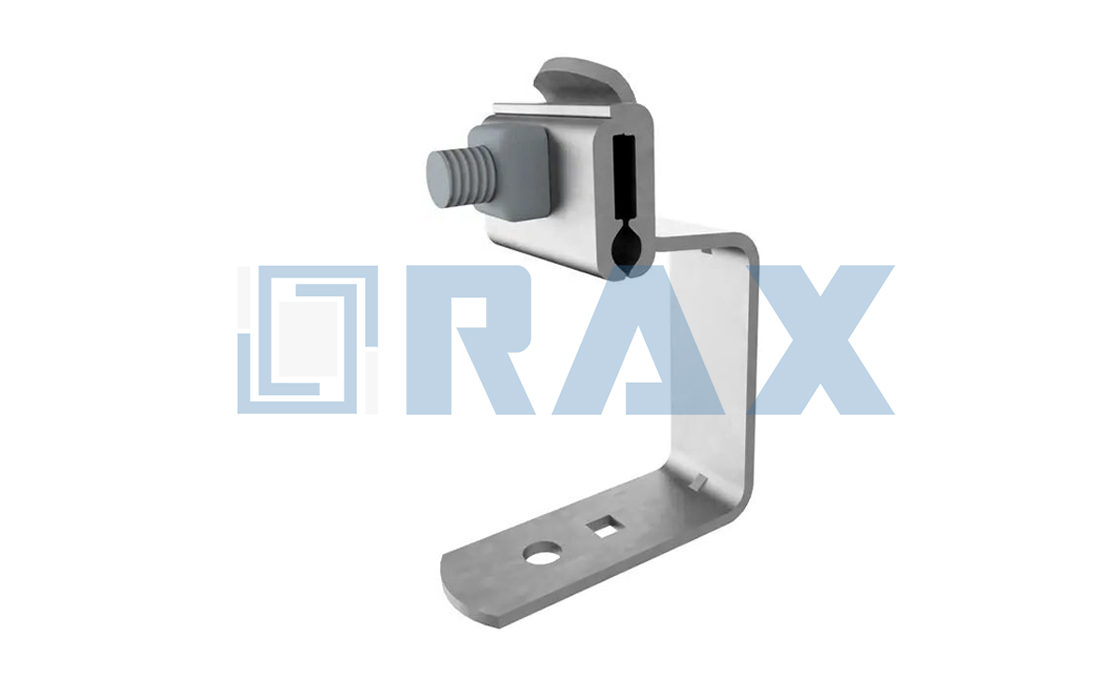

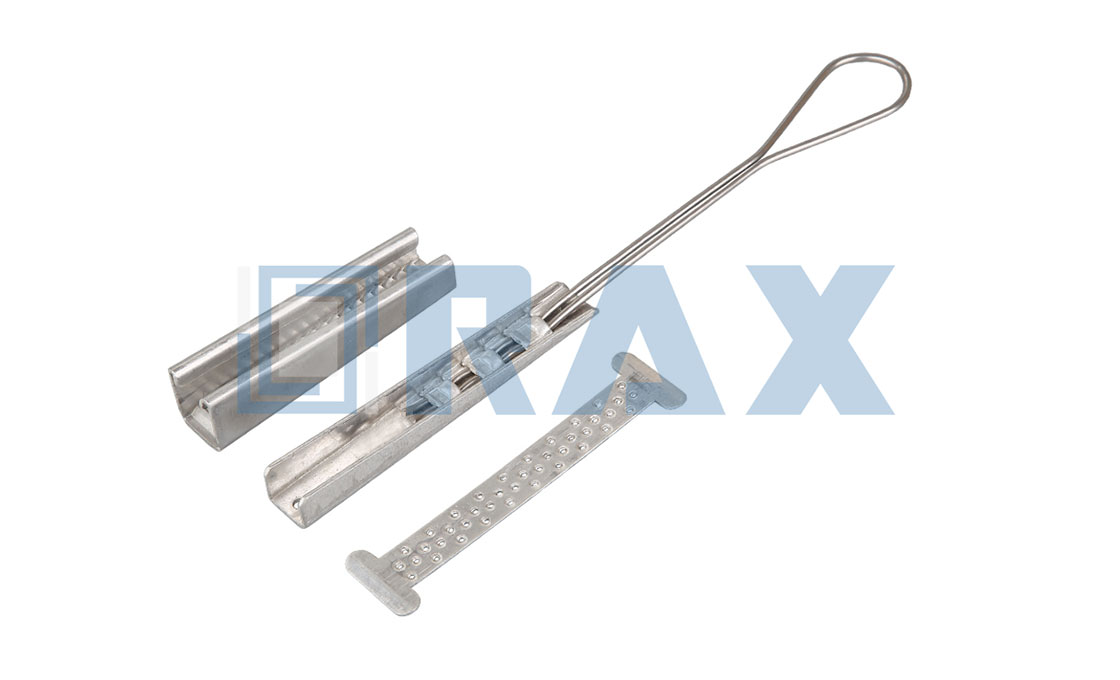

Tap Bracket

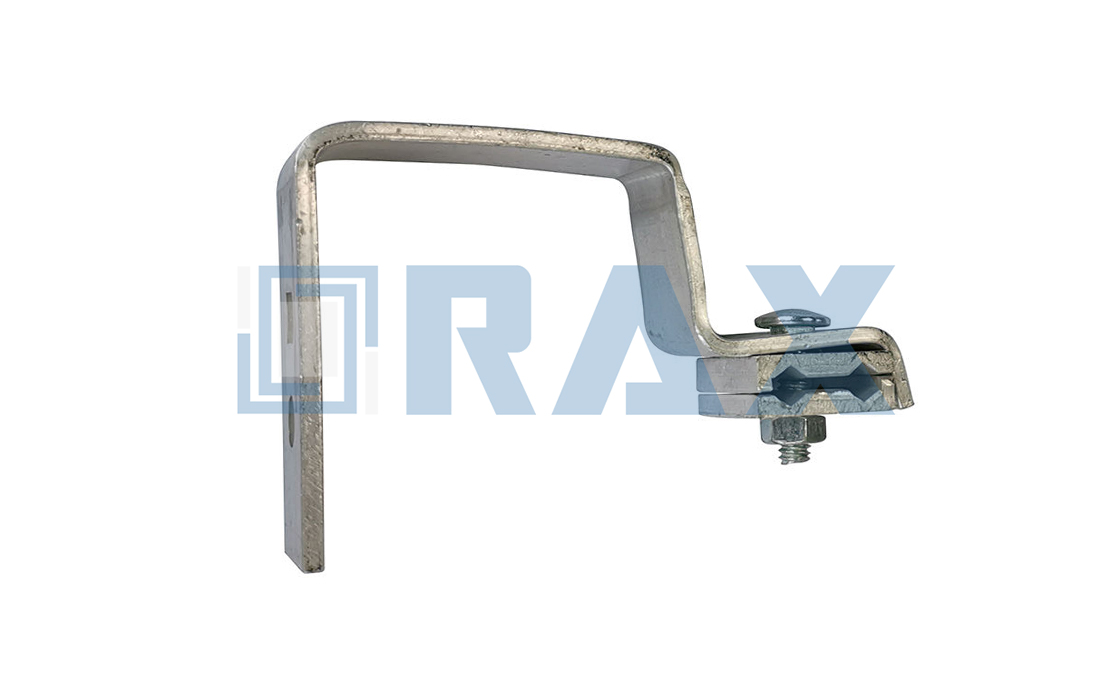

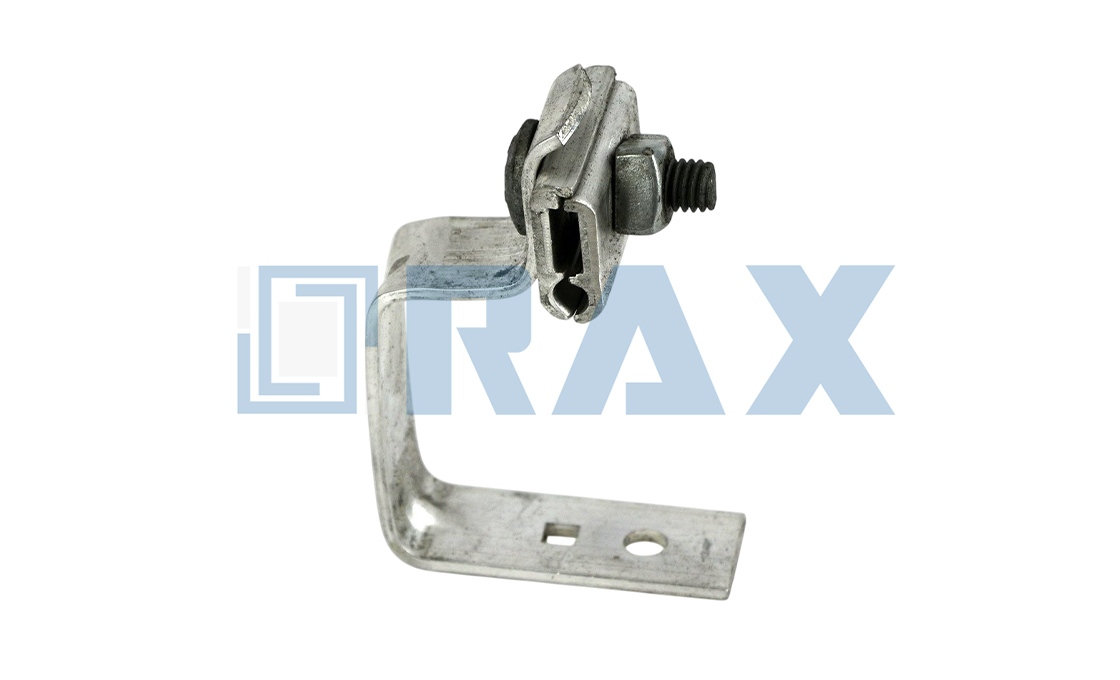

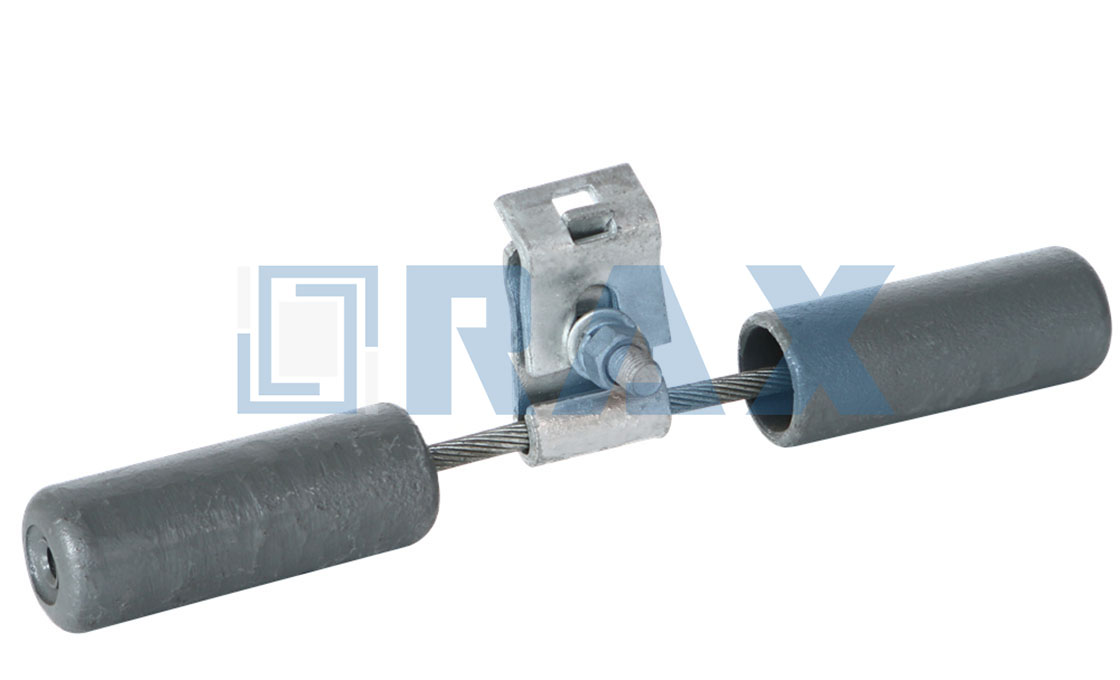

The Tap Bracket is a versatile mounting solution used primarily for securing taps and other electronic devices to overhead strands. There are main two types: standard tap Brackets and adjustable tap brackets, they are essential in telecommunications and electrical distribution systems. The Tap Bracket is designed to accommodate a range of strand sizes, typically from 1/4″ to 3/8″, and allows for the mounting of equipment at a distance of 2″ from the strand. This feature is critical for ensuring proper spacing and alignment of electrical components, enhancing both functionality and safety.

Constructed from durable materials such as aluminum and galvanized steel, the Tap Bracket is engineered for longevity and reliability in various environmental conditions. It is compatible with a variety of insulators and can be used in conjunction with products like the insulator plate, making it an integral part of many aerial cable systems. The Tap Bracket’s design allows for easy installation using standard mounting hardware, ensuring that it can be quickly deployed in both new installations and maintenance applications.

Key Features:

- Accommodates strand sizes from 1/4″ to 3/8″.

- Allows mounting of devices 2″ from the strand.

- Constructed from durable aluminum or galvanized steel.

- Compatible with various insulators for enhanced flexibility.

-

Easy installation with standard mounting hardware.

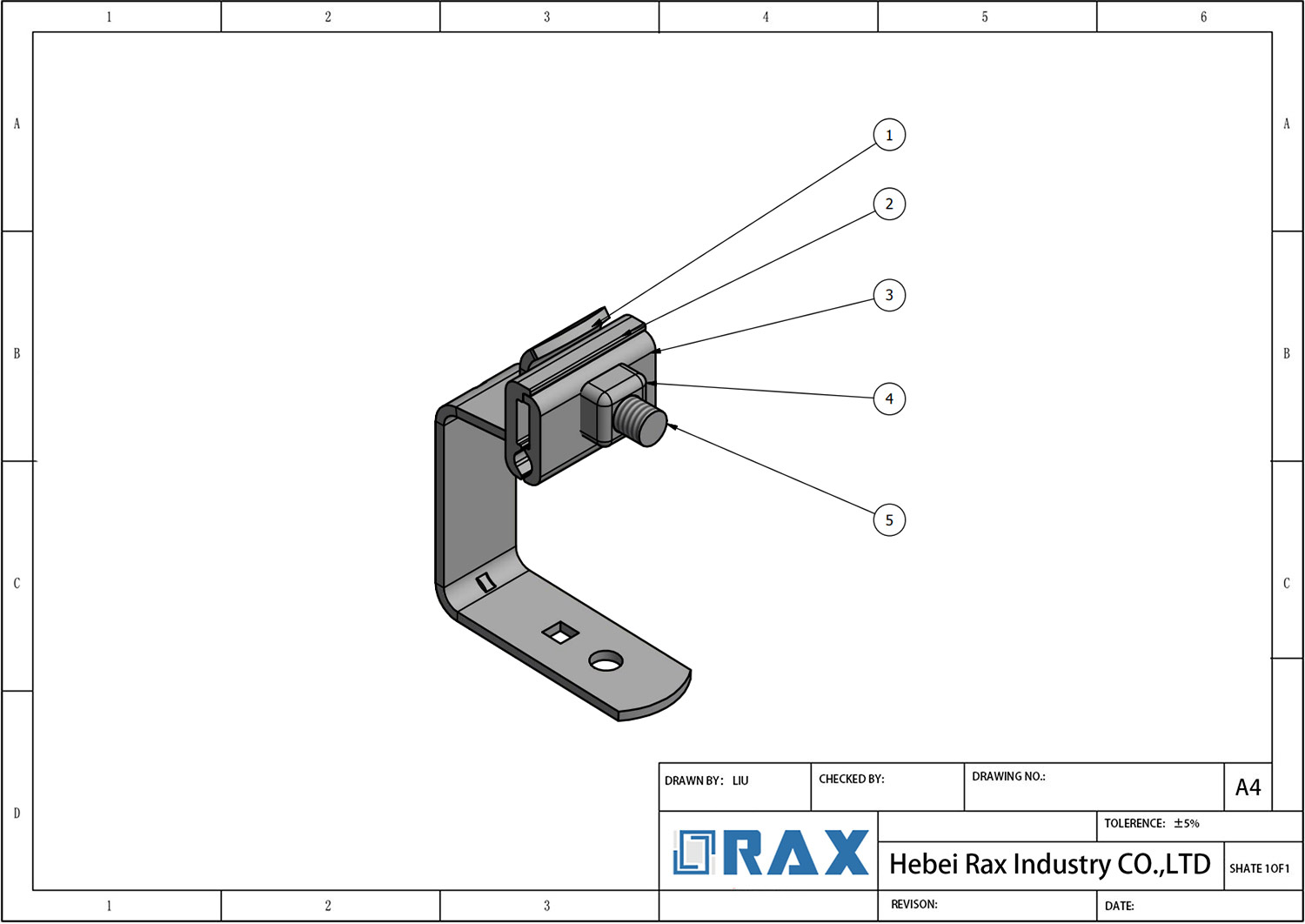

Tap Bracket Drawing

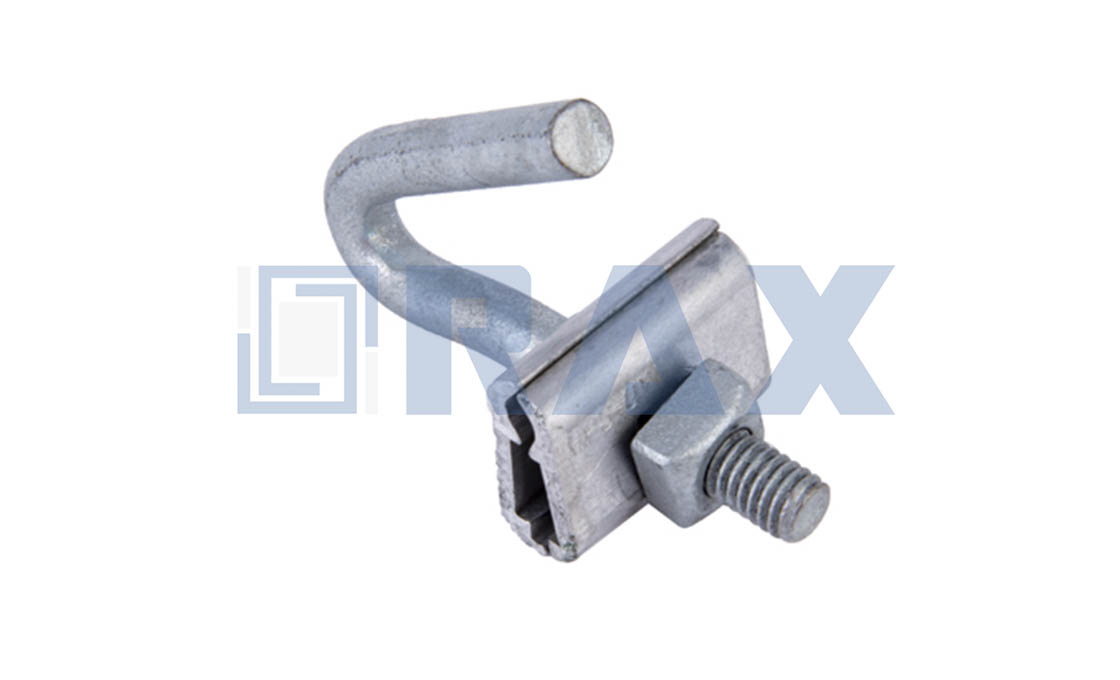

| Bill of Material | |||

| ITEM | PART NUMBER | DESCRIPTION | QTY |

| 1 | BKTATB | BRACKET | 50 |

| 2 | BNABKT | BUGNUT”A” | 50 |

| 3 | BNBBKT | BUGNUT”B” | 50 |

| 4 | HDWETMK | SQUARE NUT 3/8-16 | 50 |

| 5 | HDWETMKNUT | CARRIAGE BOLT 3/8-16 X 1 1/4 | 50 |

Frequently Asked Questions (FAQ)

What is the purpose of the Tap Bracket?

Tap Brackets are essential components used in electrical and telecommunications applications for securely attaching cables to poles or other structures. They ensure proper alignment and support, facilitating efficient installation and maintenance.

How do I install a Tap Bracket?

To install a Tap Bracket, first ensure that the surface is clean and free from debris. Position the bracket at the desired location, align it with the mounting holes, and secure it using appropriate fasteners. Always refer to the manufacturer’s installation guide for specific instructions.

What materials are Tap Brackets made from?

Tap Brackets are typically constructed from durable materials such as aluminum or galvanized steel. These materials provide resistance to corrosion and mechanical stress, ensuring longevity and reliability in various environmental conditions.

What are the standard sizes of Tap Brackets?

Standard sizes for Tap Brackets include dimensions such as 1″, 1.5″, and 2″ widths, with varying lengths depending on application needs. As a leading manufacturer, we can customize sizes according to specific requirements to meet our customers’ needs.

Are there different types of Tap Brackets available?

Yes, there are various types of Tap Brackets tailored for specific applications, including those designed for fiber optic cables, power lines, and communication cables. Each type is engineered to meet unique installation requirements.

Where can I purchase Tap Brackets?

Tap Brackets can be purchased through our authorized distributors or directly from our manufacturing facility. For bulk orders or custom specifications, please contact our sales team for assistance.

What is the weight capacity of a typical Tap Bracket?

The weight capacity of a Tap Bracket varies based on its design and material construction. Most standard brackets can support loads ranging from 200 lbs to over 1000 lbs. Always refer to the product specifications for exact figures.

Can I use Tap Brackets for temporary installations?

While Tap Brackets are primarily designed for permanent installations, they can be used temporarily if properly secured. However, it’s important to regularly check their stability during use in temporary setups.