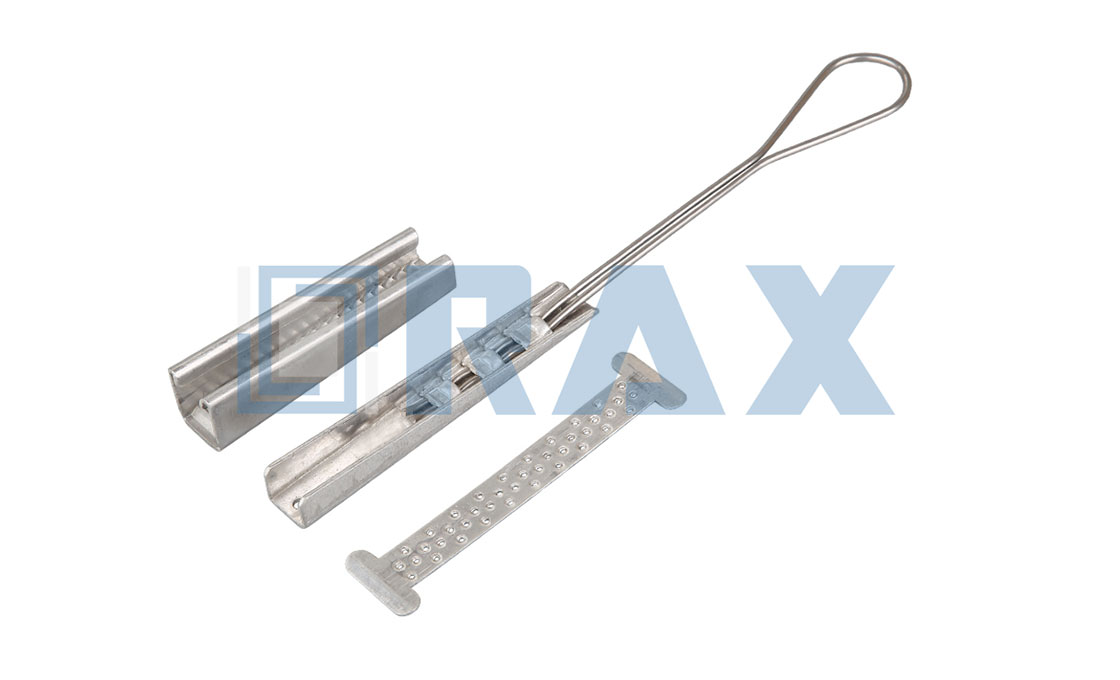

Mid Span Tap

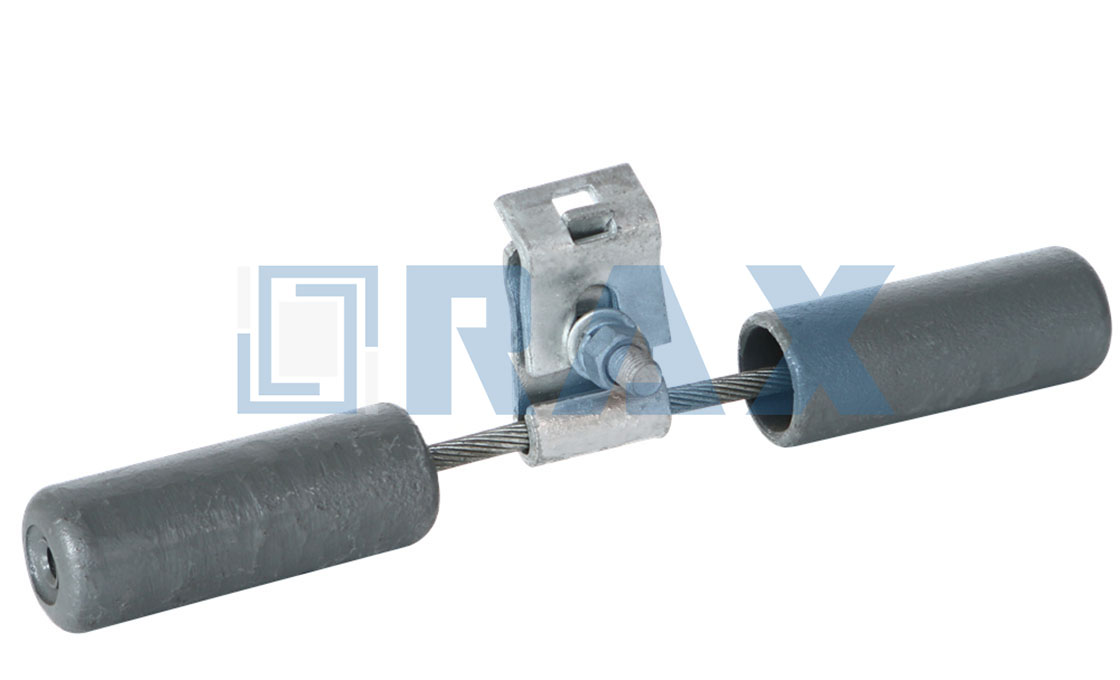

The Mid Span Tap, also known as Bolted Mid Span Clamp and Deadend, serves as a vital connector for open wire or triplex secondaries, enabling single or multiple service connections away from poles. Cast in high-strength aluminum, these clamps provide exceptional corrosion resistance and conductor compatibility for secondary service drops, offering both electrical and mechanical neutral connections.

The Mid Span Tap features a wide-angle bell mouth design that accommodates tap-offs up to 45 degrees in either direction from the clamp’s center line. They incorporate long, contoured contact surfaces that protect conductors while maintaining optimal electrical connectivity. The combination connector and deadend structure allows service deadends to attach through side loops at various angles, making them versatile for different installation requirements.

Key Features:

- Cast aluminum construction ensures superior corrosion resistance and conductor compatibility

- Wide-angle bell mouth opening supports 45-degree tap-offs in both directions

- Factory-assembled components with 12-inch conductor spacing

- Side loop connections permit installation at any angle

- Long contoured contact surfaces provide enhanced conductor protection

Frequently Asked Questions (FAQ)

What is a Mid Span Tap used for?

Mid Span Taps are used on open wire or triplex secondaries for single or multiple service connectors away from the pole. They provide both electrical and mechanical neutral connections for secondary service drops, allowing installation at various angles through side loops.

What materials are Mid Span Taps made from?

Mid Span Taps are manufactured using cast, high-strength aluminum alloy for the body, providing excellent corrosion resistance and conductor compatibility. They feature stainless steel bolts and hardware for durability and long-term performance.

What are the installation features?

The design includes wide angle bell mouth openings permitting tap offs up to 45° in either direction. Long, contoured contact surfaces protect the neutral from service pull. Side opening keepers allow easy insertion and quick connections without unclamping the run conductor.

What are the standard sizes available?

Our standard conductor diameter ranges include 0.198-0.563 inches for models GM102A/GM124A/GM125A and 0.25-0.677 inches for GM104A. As a leading manufacturer, we can customize sizes according to specific requirements beyond these standard ranges.

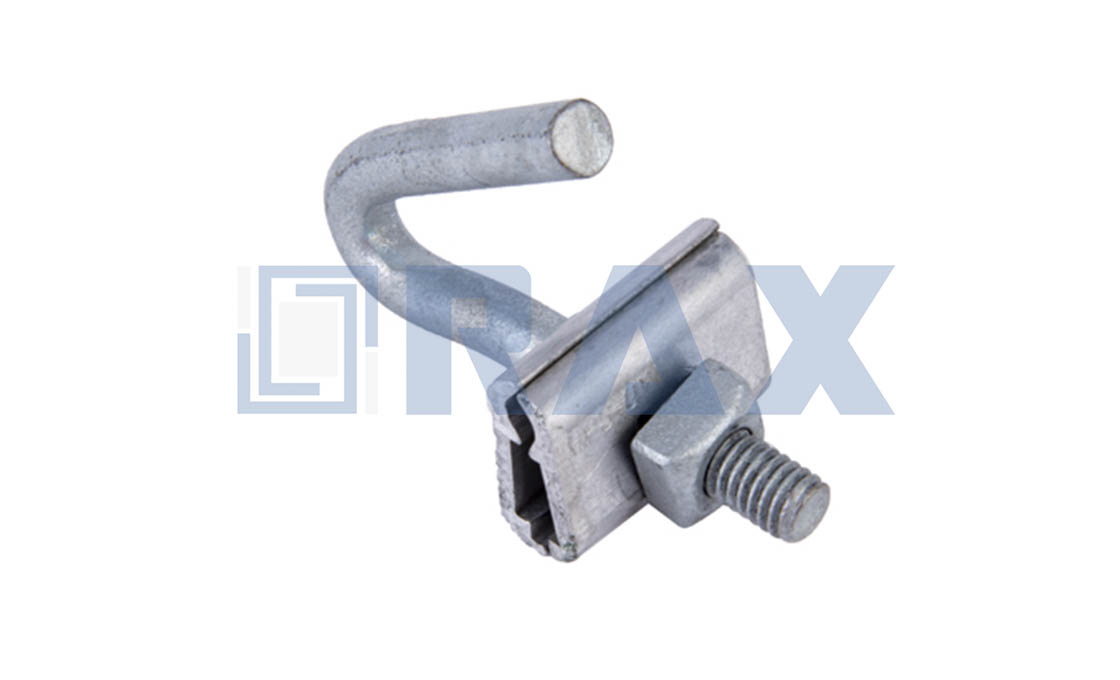

How are service deadends attached?

Service deadends of either rigid or flexible bail types can be easily installed on the projecting hooks of the clamp body. The hook design retains the bail in position during vibration or shock loading of either the secondary neutral or service.

What are the key safety features?

Double clamping of the run provides parallel current paths for enhanced safety. The design includes fitted grooves to protect covered phase wire when installed on triplex secondaries, and the bail retention system prevents disconnection during vibration.