Wedge Tap Connector

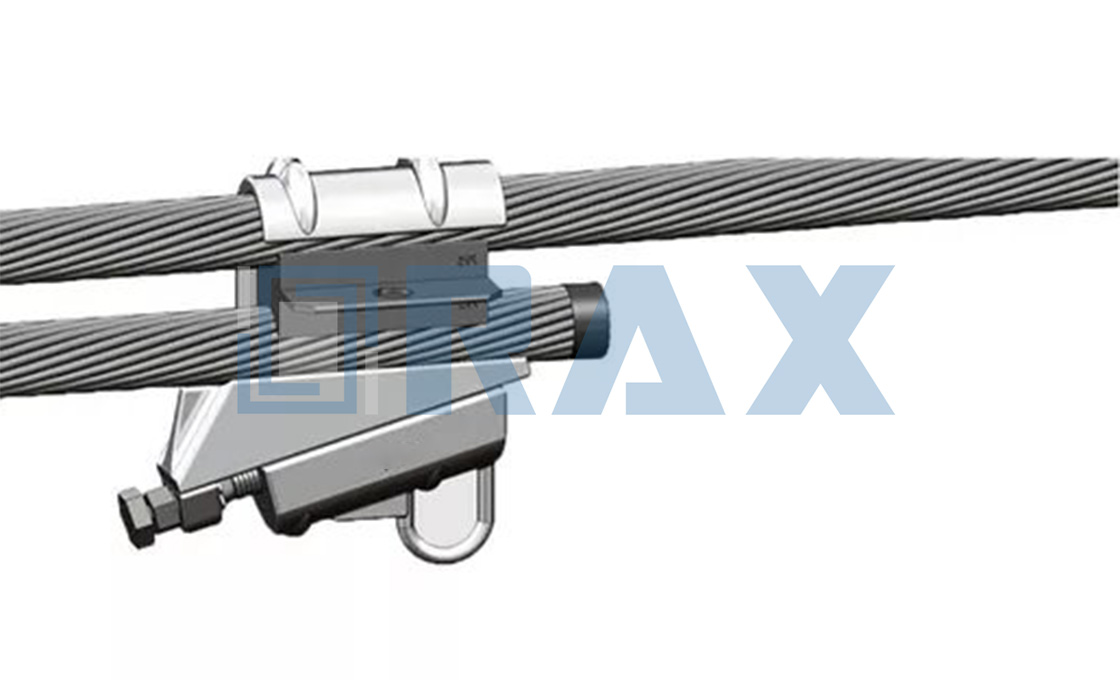

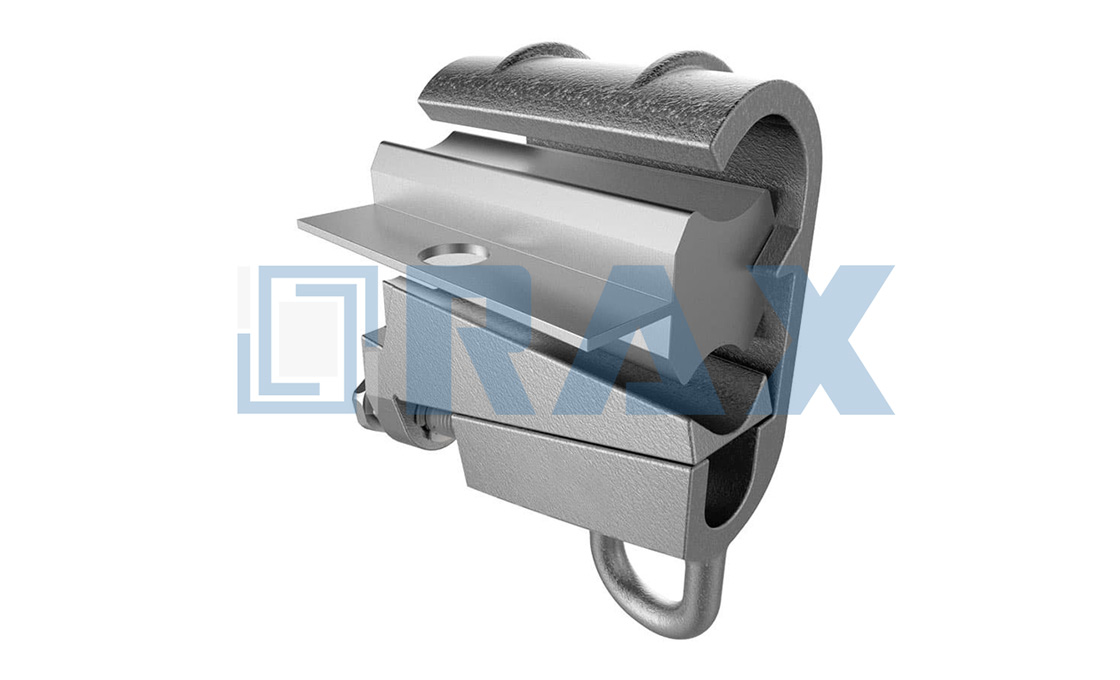

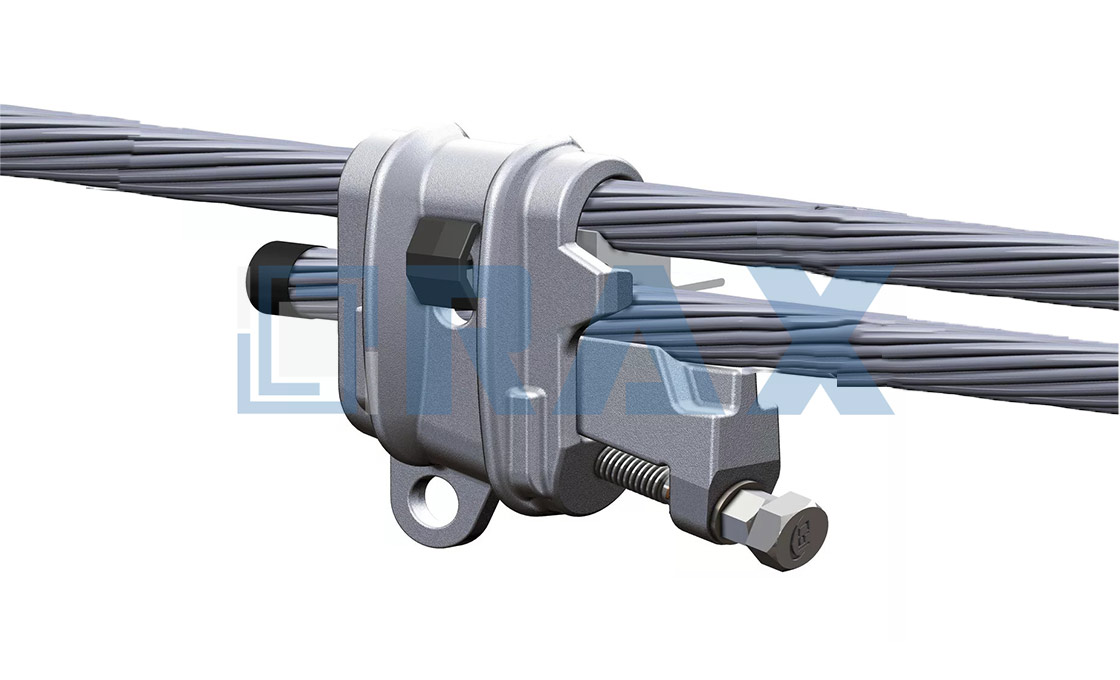

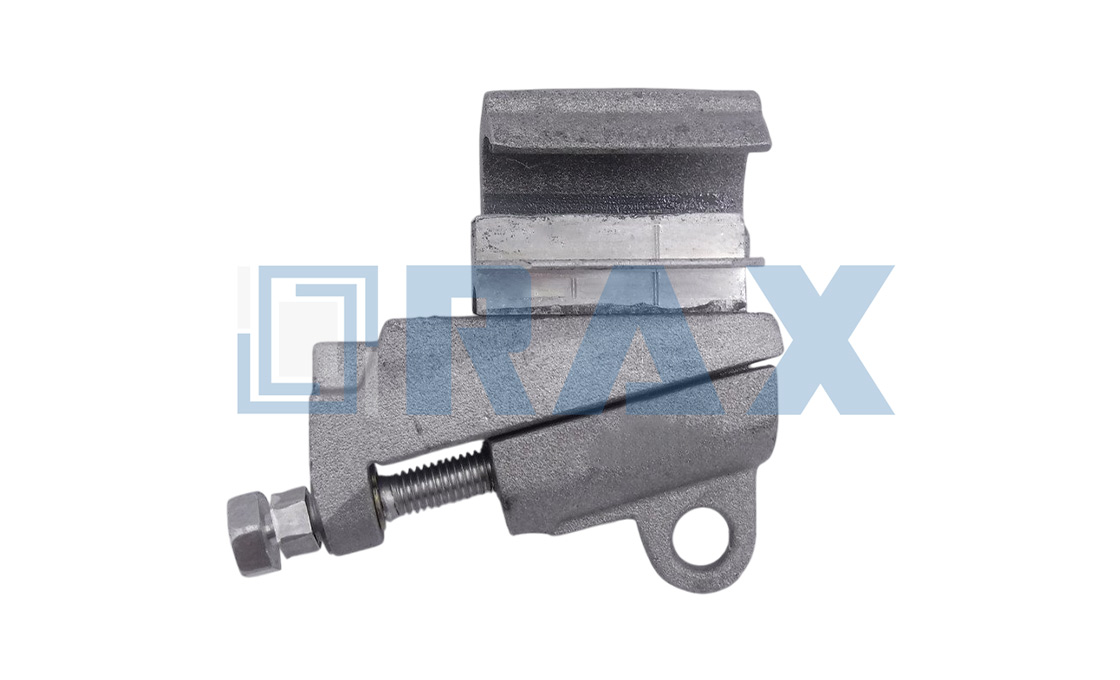

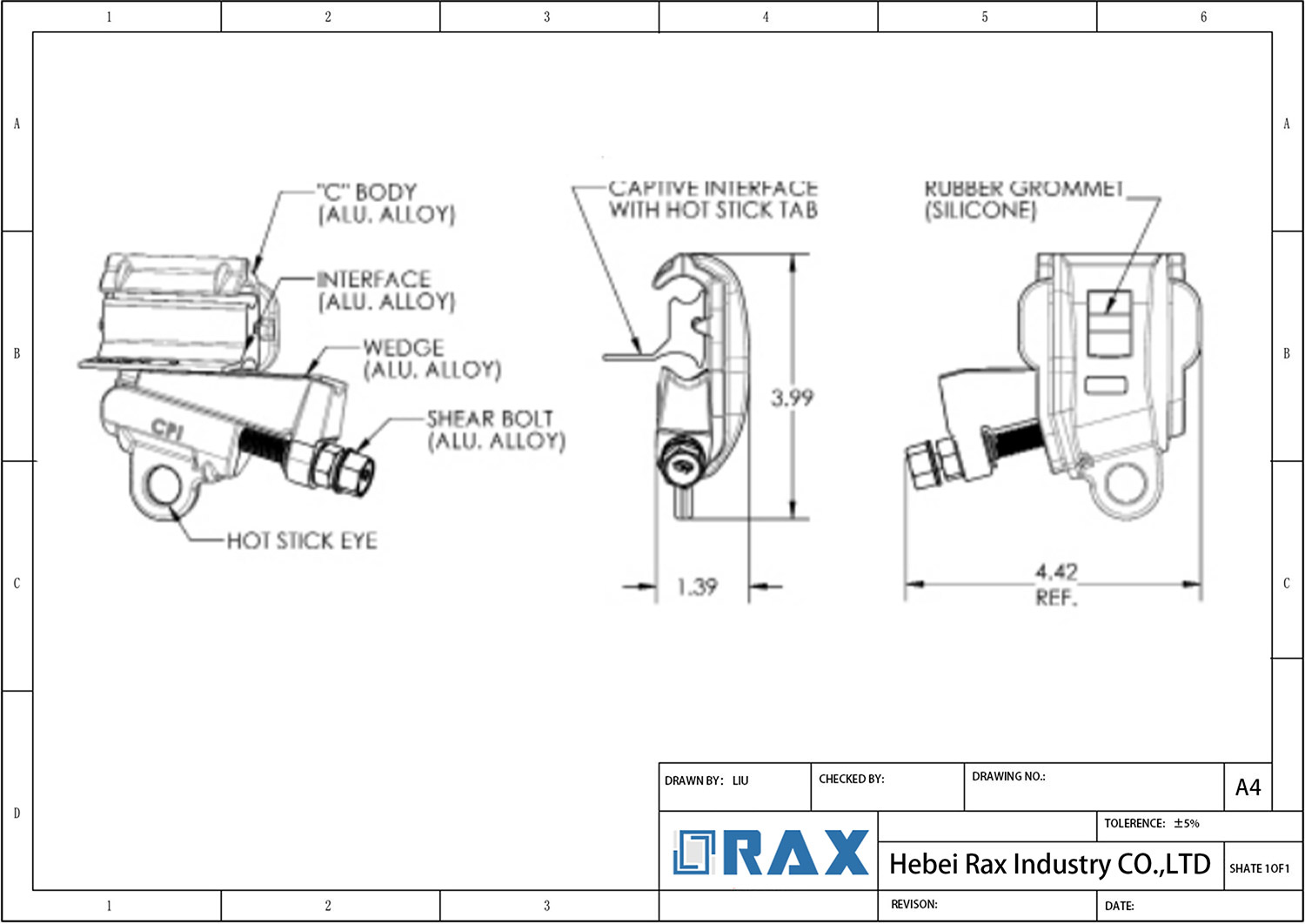

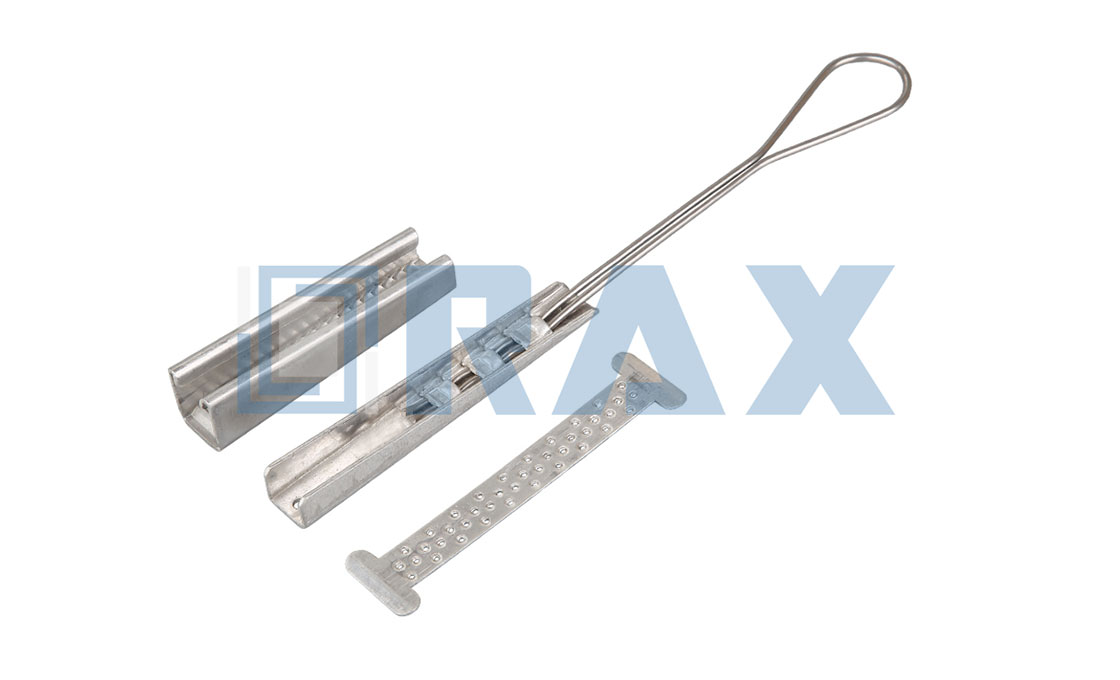

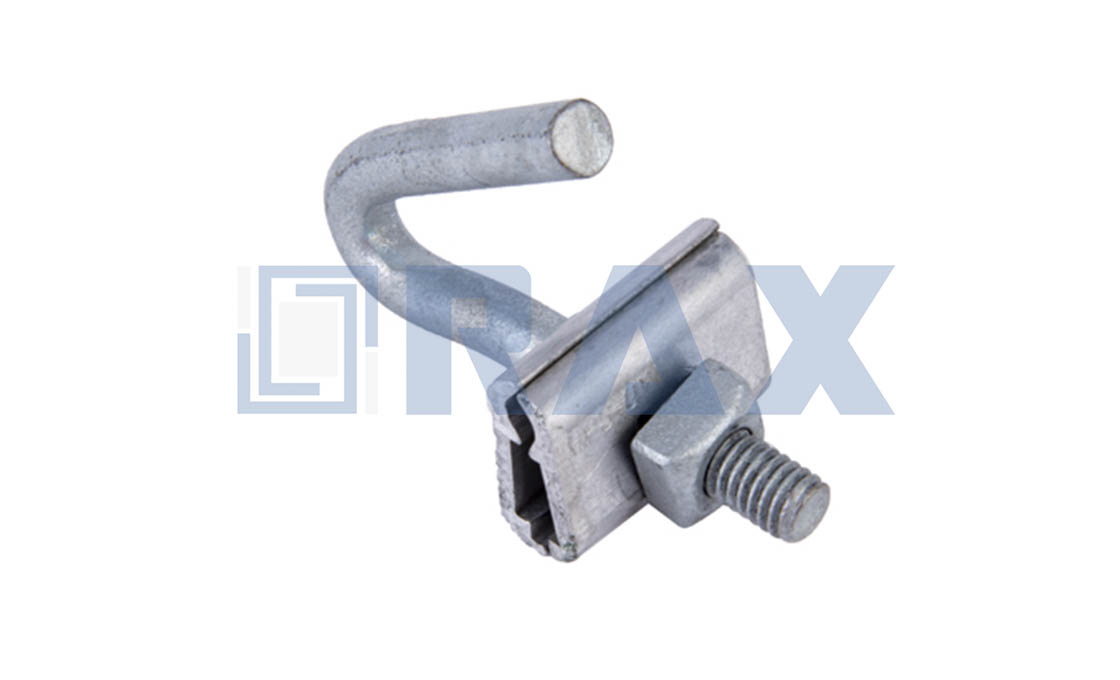

The Wedge Tap Connector is a type of Distribution Connector, serve as vital components in power distribution systems. These connectors create secure electrical connections between aluminum-to-aluminum and aluminum-to-copper conductors through wedge pressure technology. The connectors employ a C-shaped body design with a metal wedge that secures two conductors at opposing ends. Installation requires a specialized connector tool that drives the wedge at approximately 40 meters per second, effectively breaking surface oxides for optimal electrical contact.

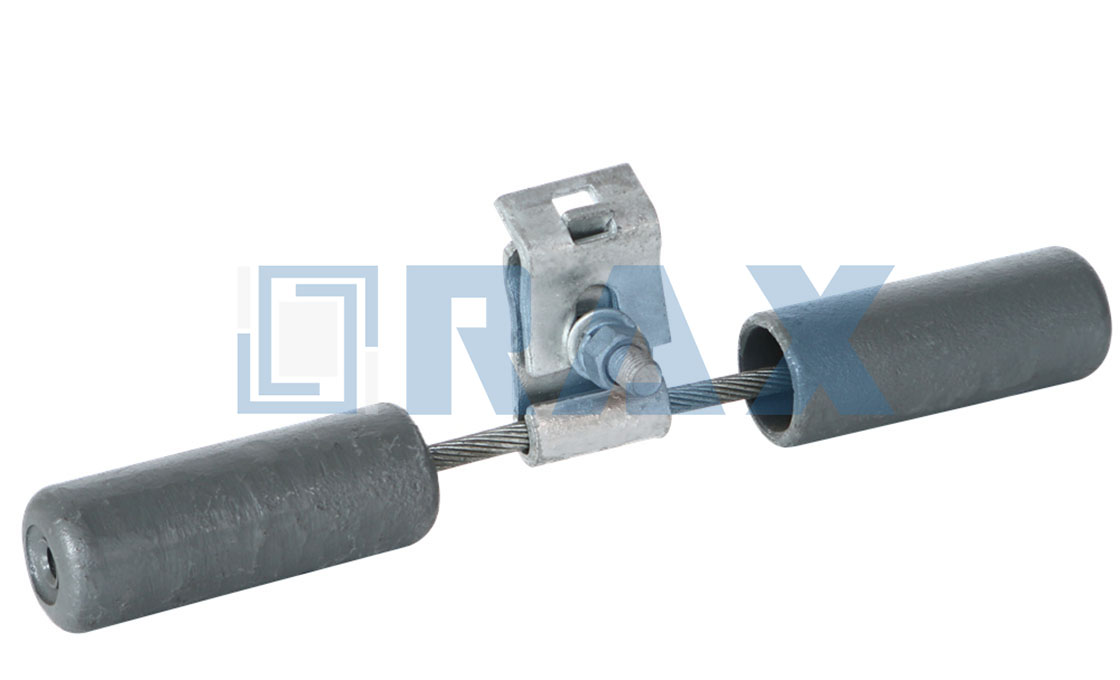

The Wedge Tap Connectors excel in distribution power lines, connecting various conductor types including ACSR, AAC, AAAC, and copper conductors. They maintain constant pressure during thermal cycling through the elastic properties of the C-shaped body. The connectors handle peak power transmission up to 250 degrees and work seamlessly with wave trap connections, insulator connections, breaker connections, and transformer connections. A pre-filled inhibitor compound within the electrical interfaces protects contact points from corrosion.

Features:

- Shearhead bolt system ensures consistent installation torque and provides visual confirmation

- Reusable design allows easy removal without conductor damage

- Spring system connection maintains permanent tightening for reliable performance

- High-speed wedge insertion creates multiple contact spots for superior conductivity

- Compatible with multiple conductor materials including AAC, AAAC, ACSR, and copper alloys

Wedge Tap Connector Drawing

| Catalog Number | Conductor | |||

| Main | Main Dia. Range | Tap | Tap Dia. Range | |

| 640101F | #6 | 0.162″-0.232″ | #6, #4 SOLID | 0.162″-0.204″ |

| 240100F | #4,#2,#1 AAC | 0.232″-0.328″ | #6, #4 SOLID | 0.162″-0.204″ |

| 240101F | #4 | 0.232″-0.257″ | ||

| 240102F | # 2,#1AAC | 0.292″-0.328″ | ||

| 210103F | #1 ACSR, 1/0, 2/0 AAC | 0.354″-0.414″ | #6 ACSR, #4 AAC | 0.198″-0.232“ |

| 210105F | #4,#2,#1 AAC | 0.232″-0.328” | ||

| 210106F | #1 ACSR, 1/0,2/0 AAC | 0.354″-0.414″ | ||

| 230107F | 2/OACSR, 3/0 | 0.447″-0.502″ | #6 ACSR, #4 AAC | 0.198“-0.232“ |

| 230108F | #4,#2,#1 | 0.232″-0.354″ | ||

| 230110F | #1 ACSR, 1/0,2/0 AAC | 0.354″-0.414″ | ||

| 230111F | 2/0 ACSR, 3/0 | 0.447″-0.502″ | ||

| 264111F | 3/0ACSR.4/0 250 AAC | 0.502″-0.574″ | #6 ACSR, #4, #1 AAC | 0.198″-0.328” |

| 264113F | #1 ACSR, 1/0,2/0 AAC | 0.316″-0.414″ | ||

| 264114F | 2/0 ACSR, 3/0 | 0.447″-0.502″ | ||

| 264115F | 4/0,250 AAC | 0.522″-0.574″ | ||

| 350117F | 266.8 ACSR, 300 MCM, 336.4 AAC 336.4 ACSR 18/1,350 MCM | 0.609″-0.684″ | #6, #4 AAC | 0.162“-0.232″ |

| 350118F | #4 | 0.232″-0.257″ | ||

| 350119F | # 2,#1AAC | 0.292″-0.328″ | ||

| 350120F | #1,1/0 AAC | 0.328″-0.368″ | ||

| 350121F | 1/0 ACSR, 2/0 | 0.398″-0.447″ | ||

| 350122F | 2/0 ACSR, 3/0 | 0.447″-0.502″ | ||

| 350123F | 4/0,250 | 0.522″-0.574″ | ||

| 350124F | 266.8-19 AAC, 300 AAC, 266.8 ACSR | 0.592″-0.642″ | ||

| 350125F | 300 ACSR | 0.665″-0.684″ | ||

Frequently Asked Questions (FAQ)

What is a Wedge Tap Connector?

What is a Wedge Tap Connector?

A Wedge Tap Connector uses an aluminum alloy wedge driven between run and tap cables, locking them into a “C” shaped tempered aluminum alloy spring-body. The spring-body maintains consistent pressure throughout the connection’s life to ensure reliability during severe electrical and climatic conditions.

How does the installation process work?

Installation involves placing the connector on the main conductor, inserting the tap conductor, and driving the wedge using either a powder-actuated tool or bolt-actuated system. The wedge creates a wiping action that removes oxidation and establishes multiple contact points, ensuring a reliable connection.

What conductor materials are compatible?

Wedge Tap Connectors can be used on aluminum, aluminum alloy, stranded aluminum composite conductors including AAC, AAAC, ACSR, ACAR, AW, ACSR/AW, and ACSS. In non-corrosive environments, they can also be used on copper conductors.

What are the standard sizes available?

Common sizes include:

- Small taps (White): #8 AWG to 1/0 AWG

- Medium taps (Blue): 2/0 AWG to 350 kcmil

- Large taps (Yellow): 336.4 kcmil to 1033.5 kcmil As a leading manufacturer, we can customize sizes according to specific requirements.

Can the connector be removed and reused?

Yes, the connector can be easily removed without damaging the conductors. For bolt-actuated types, simply back out the bolt to remove the wedge. For powder-actuated types, special removal tools are available.

What is the temperature rating?

Standard Wedge Tap Connectors operate up to 90°C continuous, while High Temperature versions (HTT) can handle up to 250°C for use on ACSS overhead lines.

How do I ensure proper installation?

Clean conductors thoroughly before installation, ensure correct wedge orientation (large groove aligned with main conductor), and verify complete wedge insertion. For bolt-actuated types, the shear-head bolt must break to indicate proper installation torque.

What are the color codes for different sizes?

Connectors are color-coded for easy identification:

- White: Small taps (#8 AWG – 1/0 AWG)

- Blue: Medium taps (2/0 AWG – 350 kcmil)

- Yellow: Large taps (336.4 kcmil – 1033.5 kcmil)

What is a Wedge Tap Connector?

What is a Wedge Tap Connector?