Compression Cable Lug

Compression cable lugs are devices used to connect electrical wires to copper or tinned copper conductors. They anchor or fasten non-electrical cables to surfaces, mounting plates, or other cables.

Cable lugs also allow thick cables to be attached to a connector with a smaller diameter by acting as a cable-size reducer. They are commonly used in electrical appliances, automotive wiring, telecommunications, and electronics.

To create a secure connection, the cable lugs are usually compressed or crimped onto the cable conductor. They are designed to be easily installed and removed for repairs or maintenance, making them an ideal fastening solution ideal when permanent methods are not required.

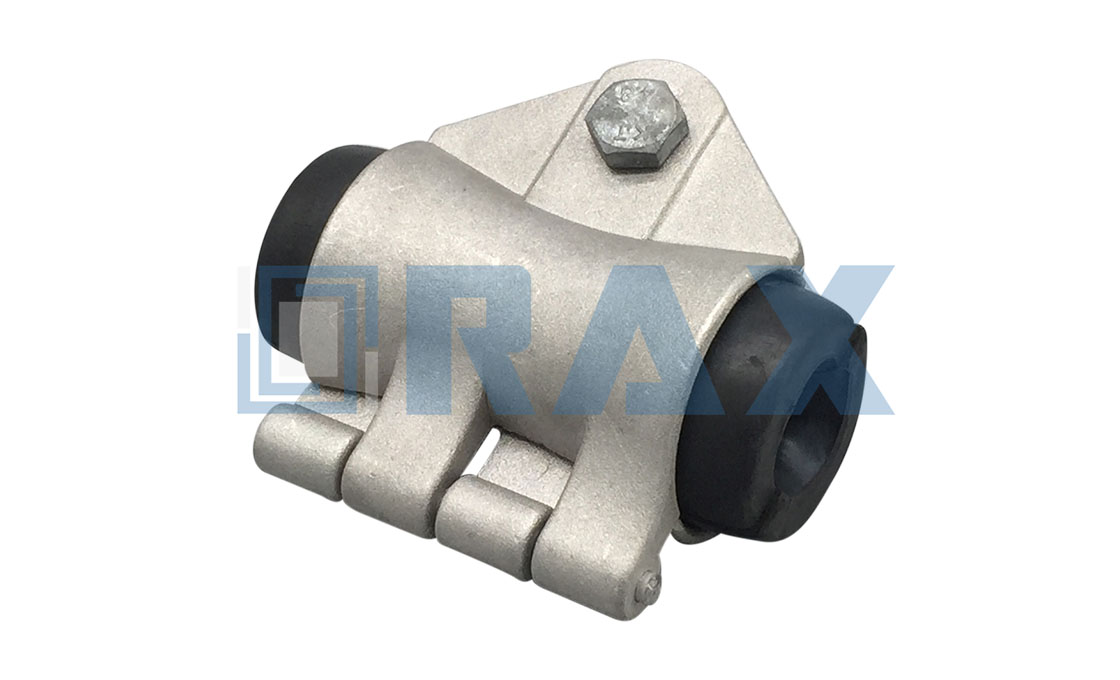

There are various types of cable lugs designed to suit different applications including two-hole, single-hole, heavy-duty, and more. Some cable lugs such as those used for electrical connections are insulated with rubber or plastic for safety.

The appropriate type of compression cable lug typically depends on the terminal type or anchoring method. Fork or U-shaped lugs are used for screw terminals while closed-ring or O-type lugs are used for bolt-on applications. For blade or press-on pin terminals, pin or spade lugs are used.

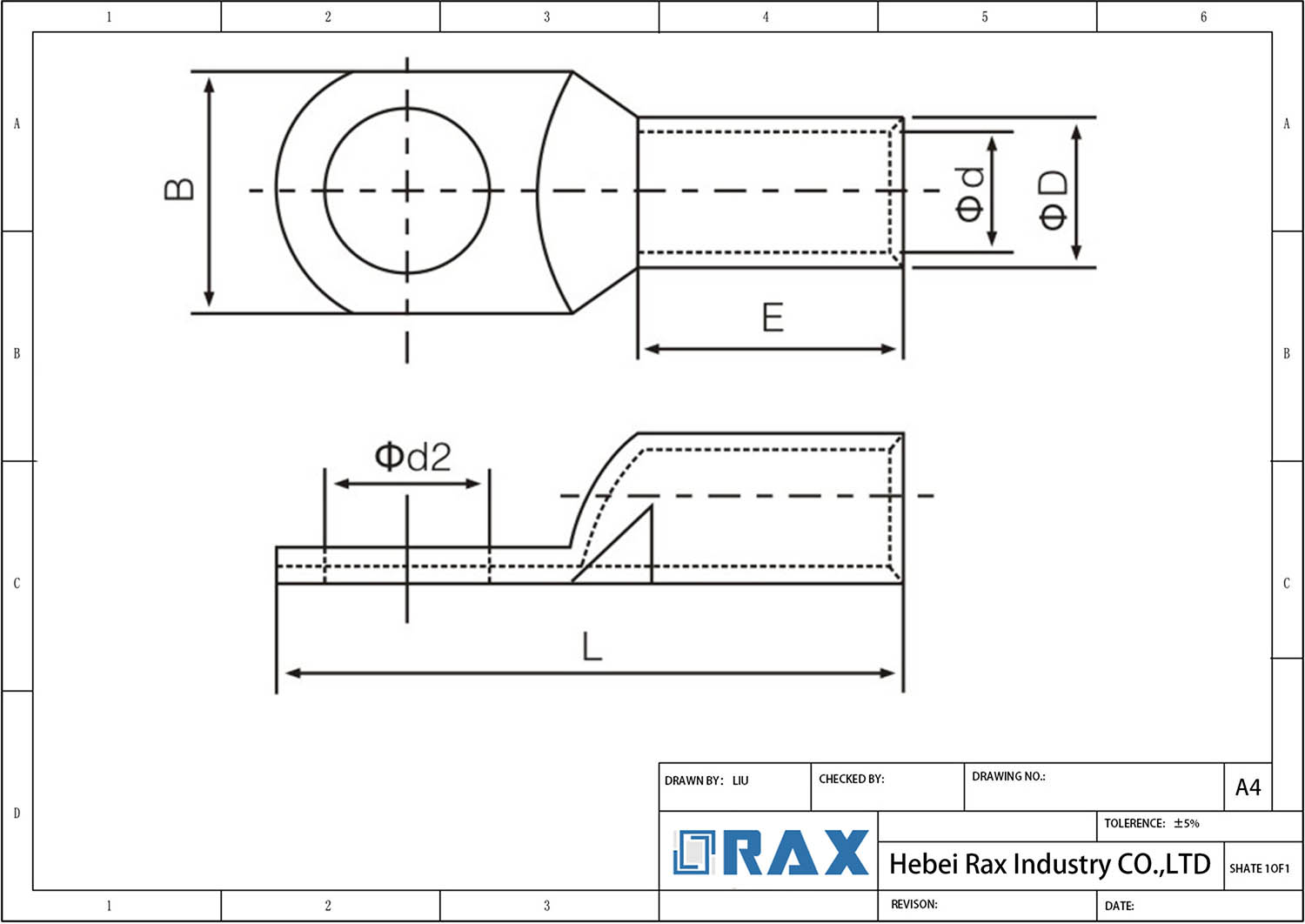

Compression Cable Lug Drawing

| ITEM NO. | Dimension(mm) | |||||

| Φd2 | B | L | ΦD | Φd | E | |

| CL14-H-6 | 6.4 | 18.3 | 50 | 8.8 | 5.8 | 28.5 |

| CL22-H-8 | 8.4 | 18.3 | 52 | 11.3 | 7.7 | |

| CL38-H-10 | 10.5 | 18.3 | 64 | 12.4 | 9.8 | 34 |

| CL38-H-12 | 13 | 18.3 | 64 | |||

| CL60-H-10 | 10.5 | 20.5 | 70 | 14 | 11 | 36 |

| CL60-H-12 | 13 | 20.5 | 70 | |||

| CL70-H-10 | 10.5 | 21.4 | 72 | 15 | 12 | 38 |

| CL70-H-12 | 13 | 21.4 | 72 | |||

| CL80-H-12 | 13 | 23.2 | 75 | 16 | 13 | |

| CL100-H-12 | 13 | 26 | 75 | 18 | 14 | 40 |

| CL125-H-12 | 13 | 28 | 85 | 20 | 16 | |

| CL150-H-12 | 13 | 31.5 | 94 | 22 | 17 | 46 |

| CL180-H-12 | 13 | 33 | 98 | 23 | 18.2 | |

| CL200-H-12 | 13 | 37 | 104 | 26 | 20 | 48 |

| CL250-H-12 | 13 | 41 | 114 | 28 | 22 | |

| CL325-H-12 | 13 | 46 | 118 | 32 | 25 | 50 |

| CL400-H-12 | 13 | 54 | 130 | 37 | 30 | 60 |

| CL500-H-12 | 13 | 57.5 | 150 | 40 | 31 | |

| B-CL14-H-6 | 6.4 | 18.3 | 50 | 8.3 | 5.8 | 28.5 |

| B-CL22-H-8 | 8.4 | 18.3 | 52 | 10.7 | 7.7 | |

| B-CL38-H-10 | 10.5 | 17.2 | 64 | 11.9 | 9.8 | 34 |

| B-CL38-H-12 | 13 | 17.2 | 64 | 11.9 | 9.8 | |

| B-CL60-H-10 | 10.5 | 20 | 70 | 13.5 | 11 | 36 |

| B-CL60-H-12 | 13 | 20 | 70 | |||

| B-CL70-H-10 | 10.5 | 21.4 | 72 | 14.5 | 12 | 38 |

| B-CL70-H-12 | 13 | 21.4 | 72 | |||

| B-CL80-H-12 | 13 | 23.2 | 75 | 15.5 | 13 | |

| B-CL100-H-12 | 13 | 25.5 | 75 | 17.3 | 14 | 40 |

| B-CL125-H-12 | 13 | 28 | 85 | 19.3 | 16 | |

| B-CL150-H-12 | 13 | 30.5 | 94 | 21.1 | 17 | 46 |

| B-CL180-H-12 | 13 | 32.5 | 98 | 22.1 | 18.2 | |

| B-CL200-H-12 | 13 | 36 | 104 | 24.9 | 20 | 48 |

| B-CL250-H-12 | 13 | 39.5 | 114 | 26.9 | 22 | |

| B-CL325-H-12 | 13 | 45 | 118 | 30.7 | 25 | 50 |

| B-CL400-H-12 | 13 | 54 | 130 | 35.7 | 30 | 60 |

| B-CL500-H-12 | 13 | 56 | 150 | 38.4 | 31 | |

、

Frequently Asked Questions

How does a cable lug work?

Cable lugs connect electrical cables with terminals on conductors to create a secure connection. They are used in the installation, repair and maintenance of electrical installations and appliances. Cable lugs also find applications in automotive, telecommunications, industrial machinery, and other industries.

How do you attach a cable lug?

Cable lugs are attached by inserting the cable into the barrel of the lug and then compressing or crimping the lug to bond it to the electrical conductor. Crimping tools are used to compress the cable lug and ensure a secure connection.

How do you choose cable lug size?

When choosing the appropriate cable lug size, consider the cable diameter as well as the terminal’s attachment hole size. Most manufacturers provide a size chart for reference to help you determine the right size of cable depending on cable diameter and terminal hole size.

What is the difference between 1-hole and 2-hole lugs?

Two-hole lugs require two bolts which helps to prevent lug rotation. They also have a more contact surface leading to a better distribution of contact pressure making them ideal for heavy-duty applications. One-hole lugs are ideal for standard applications.

Key Features of Compression Cable Lugs

- Material and Coating

Cable lugs are made of copper or other high conductivity materials like aluminium. Copper, due to its high conductivity is the preferred material in lugs for use in telecommunications and electronic applications.

To prevent damage such as corrosion or oxidation, the electro-tin-plated coating may be applied to cable lugs in some cases especially when used in outdoor installations.

- Size and Type

Since cable lugs are precision devices, choosing the appropriate size and shape for the terminal type where it is being used is essential. Compression lugs are intended to attach securely to the wire to ensure mechanical stability and prevent a loose connection. It is important to check that the diameter of the slug is appropriate for the terminal hole diameter.

The appropriate type of cable lugs typically depends on the application. Two-hole lugs are designed for bus bar applications which require two bolts to prevent lug rotation. One-hole lugs are intended for standard use while long-barrel lugs work best for heavy-duty industrial applications since they can allow additional crimping for added mechanical strength.

For applications like distribution panels or circuit breakers slotted lags may be ideal since they have a U-shaped design that makes it easy to slip the lug onto a terminal.

- Mechanical Strength:

Standard barrel and short barrel lugs are ideal for lighter-duty use or in applications where space is limited. However, in applications where there are heavy mechanical loads, long barrel lugs may be ideal since they have a bigger load-bearing capacity.

Factors like the number of holes may also impact the mechanical strength of the lug with two-hole cable lugs having a higher load-bearing capacity compared to one-hole cable lugs.

Factors like corrosion and oxidation can also impact mechanical strength and durability, especially in outdoor installations so opting for cable lugs with corrosion-resistant plating like tin can boost reliability.