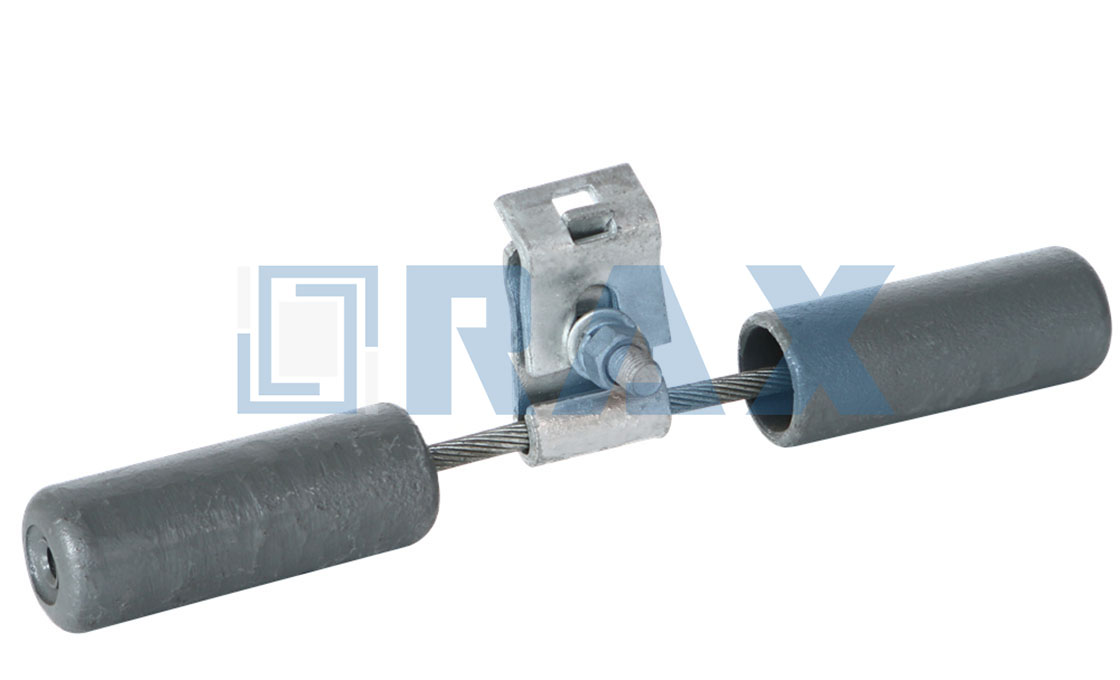

Splice Shunt

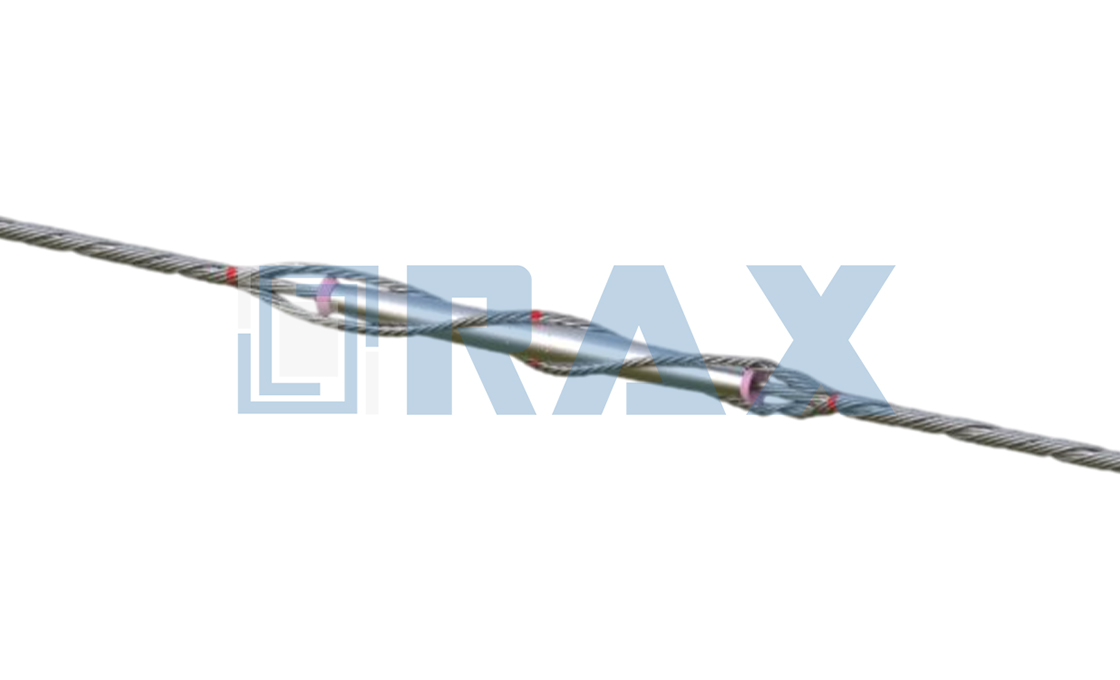

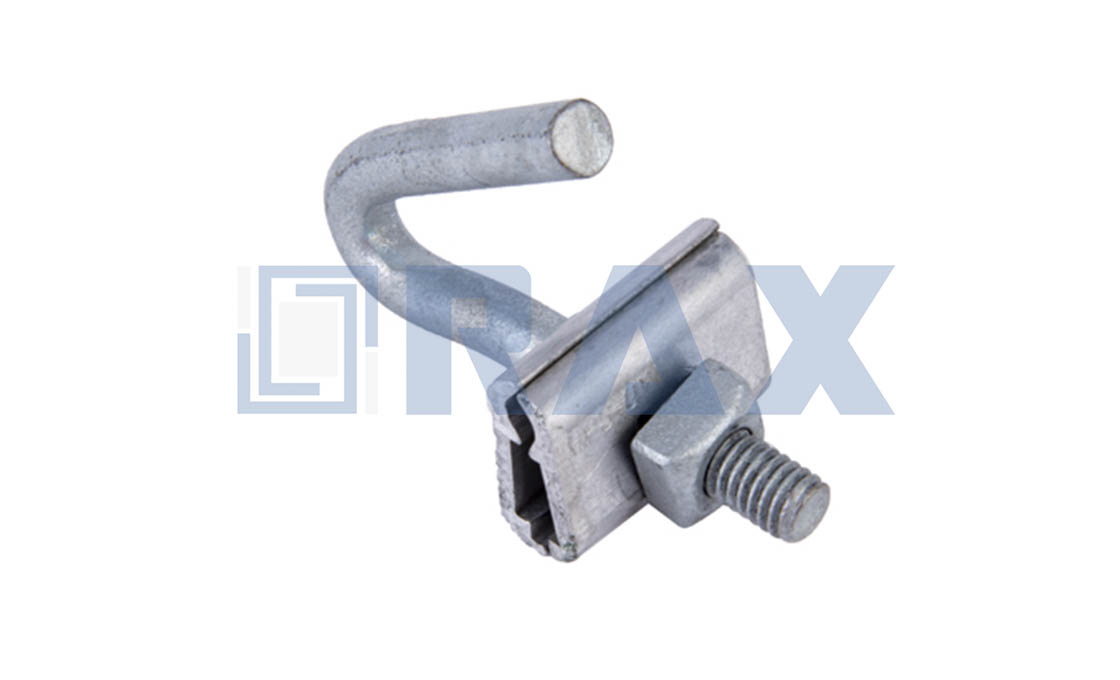

The Splice Shunt is a specialized device designed to restore electrical conductivity and mechanical strength to automatic and compression splices. It is essential for maintaining the integrity of electrical systems, especially in cases where splices have been subjected to excessive heat or failure. The Splice Shunt is particularly useful for all-aluminum, aluminum alloy, and ACSR conductors. It can be installed easily by hand or with hot sticks, making it versatile for various applications.

To use the Splice Shunt, simply install it directly over the damaged splice. This product is compatible with several models, for galvanized strand and distribution construction. The structure of the Splice Shunt allows it to fit snugly over existing splices, thereby restoring their original conductivity and mechanical strength. Additionally, it can be customized according to specific requirements, ensuring that it meets the unique needs of different electrical systems.

Key features:

- Restores full electrical conductivity and mechanical strength

- Lightweight design for easy handling

- Compatible with various conductor types

- Can be installed on energized or de-energized lines

-

Customizable sizes available based on requirements

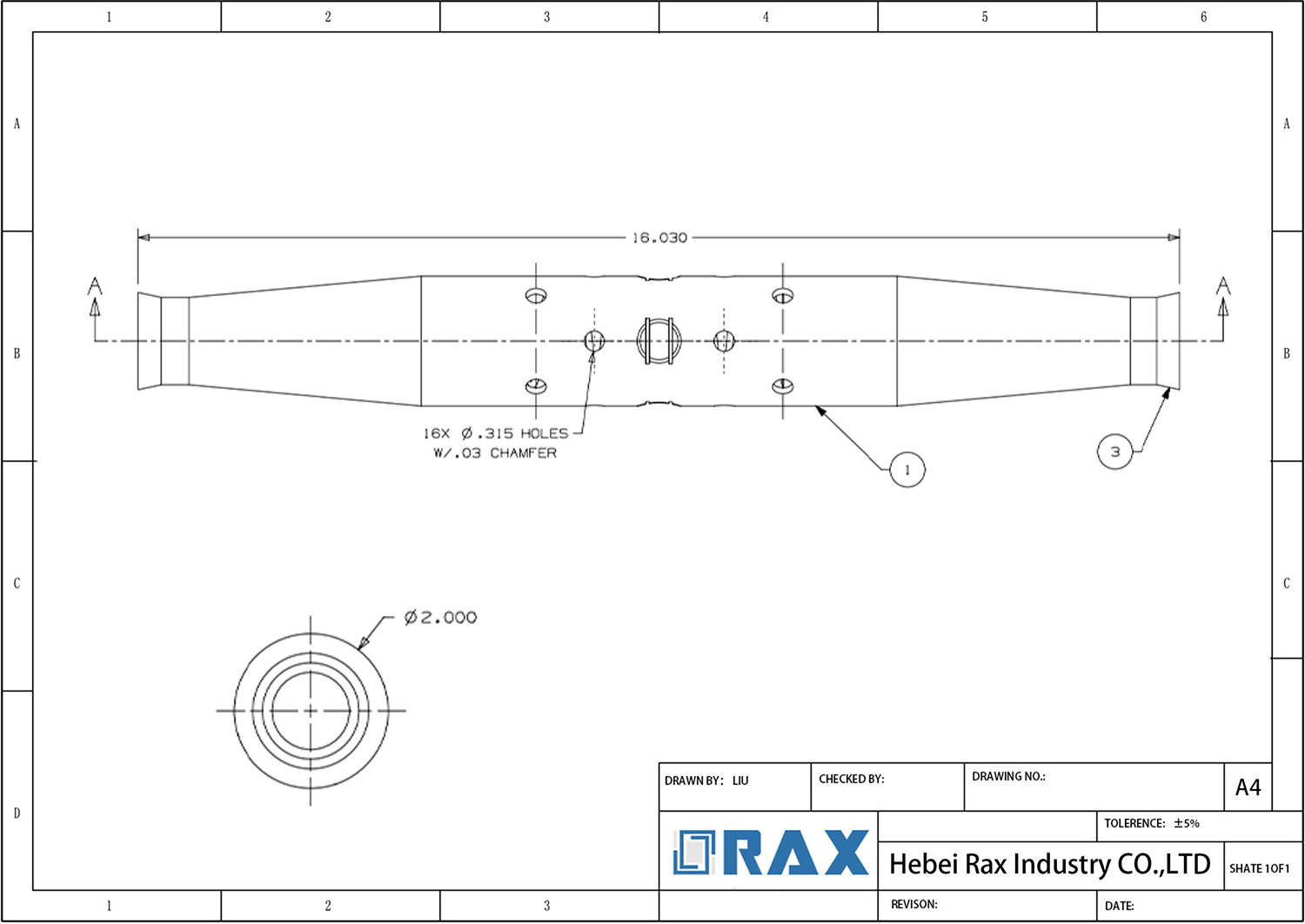

Splice Shunt Drawing

| Catalog Number | Diameter range (m) | Nominal Conductor Size | Wt./ Units Lbs. | Overall Length (in) | Max Shunt Length (in) | Rod Diameter (in) | No. of Subsets | Color Code | ||

| Min. | Max. | Per Carton | ||||||||

| SS-0001 | 0.232 | 0.257 | #4, ACSR, AAC, AAAC | 50 | 18 | 45 | 13.75 | 0.094 | 2(4-4) | Orange |

| SS-0002 | 0.292 | 0.325 | #2,ACSR, AAC, AAAC | 50 | 26 | 51 | 13.75 | 0.102 | 2 (4-5) | Red |

| SS-0003 | 0.368 | 0.398 | 1/0.ACSR, AAC, AAAC | 50 | 57 | 65 | 16.25 | 0.136 | 2 (5-5) | Yellow |

| SS-0004 | 0.414 | 0.462 | 2/0, ACSR, AAC, AAAC | 50 | 63 | 68 | 16.25 | 0.154 | 2 (5-5) | Blue |

| SS-0005 | 0.464 | 0.503 | 3/0, ACSR, AAC, AAAC | 25 | 47 | 77 | 23.5 | 0.167 | 2 (5-5) | Orange |

| SS-0006 | 0.522 | 0.567 | 4/0, ACSR, AAC, AAAC | 25 | 68 | 85 | 23.5 | 0.204 | 2 (4-5) | Red |

| SS-0007 | 0.586 | 0.618 | 266.8, 18/1, ACSR, AAAC | 10 | 38 | 96 | 23.5 | 0.218 | 2 (4-5) | Purple |

| SS-0008 | 0.619 | 0.644 | 266.8, 26/7; ACSR, AAAC | 10 | 47 | 102 | 23.5 | 0.218 | 2 (5-5) | Yellow |

| SS-0009 | 0.666 | 0.700 | 336.4, 18/1, ACSR, AAAC | 10 | 55 | 103 | 23.5 | 0.235 | 2 (5-5) | Orange |

| SS-0010 | 0.701 | 0.729 | 336.4, 26/7; ACSR | 10 | 56 | 106 | 23.5 | 0.235 | 2 (5-5) | Gree n |

Frequently Asked Questions (FAQ)

How do I install a Splice Shunt?

How do I install a Splice Shunt?

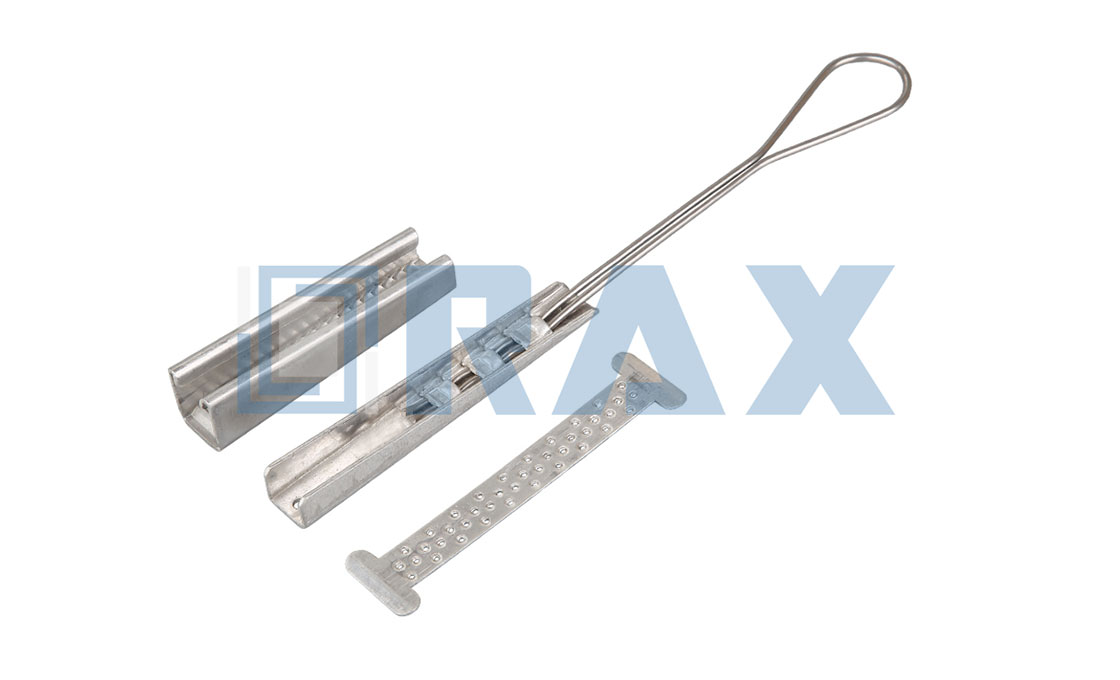

Installation involves cleaning the conductor, applying a conductive oxide inhibitor, and wrapping the shunt around the splice. The process can be done manually or using hot sticks, ensuring that the shunt is securely fastened and aligned properly for optimal conductivity.

What materials are Splice Shunts made from?

Splice Shunts are typically made from high-strength aluminum alloy, which ensures excellent electrical conductivity and durability. The design includes conductive grit on the inner surface to enhance contact with the conductor.

How do Splice Shunts improve system reliability?

By restoring both electrical and mechanical integrity to splices, Splice Shunts help prevent future failures caused by overheating. This enhances overall system reliability, reduces maintenance needs, and extends the lifespan of electrical connections in overhead lines.

Can Splice Shunts be used on energized lines?

Yes, Splice Shunts can be installed on energized lines using specialized techniques such as hot stick application. This allows for maintenance without de-energizing the line, minimizing downtime and service interruptions.

What applications are suitable for Splice Shunts?

Splice Shunts are primarily used in overhead power distribution systems, particularly where automatic and compression splices are present. They are ideal for utility companies looking to enhance the performance of their electrical networks.

How do I install a Splice Shunt?

How do I install a Splice Shunt?