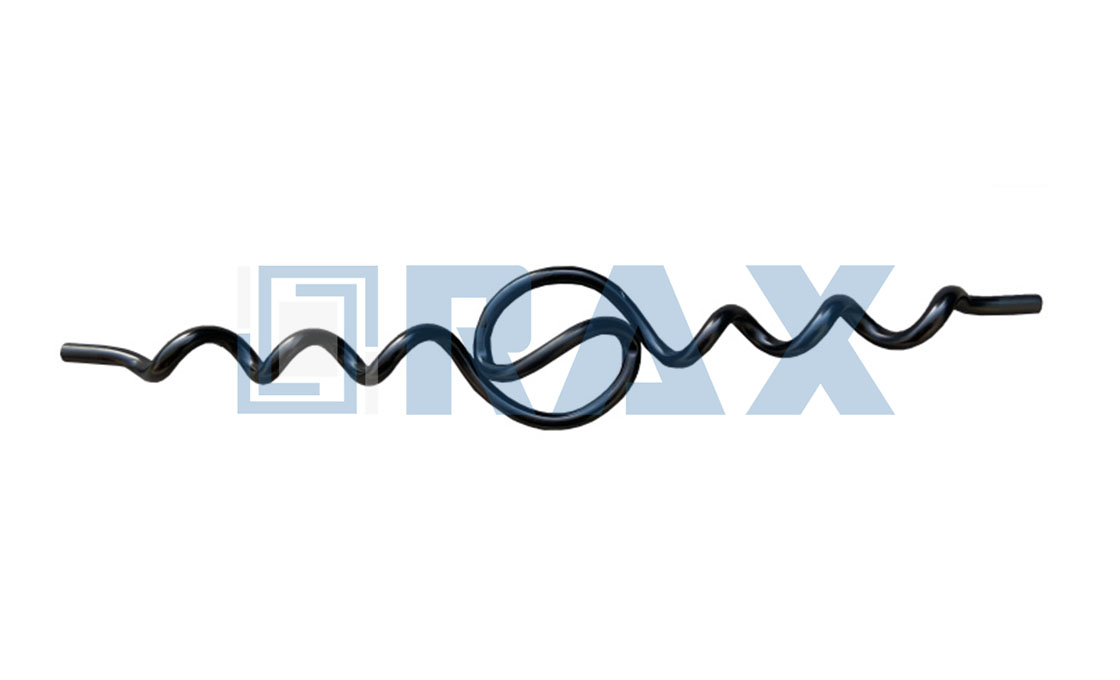

Lashing Rod

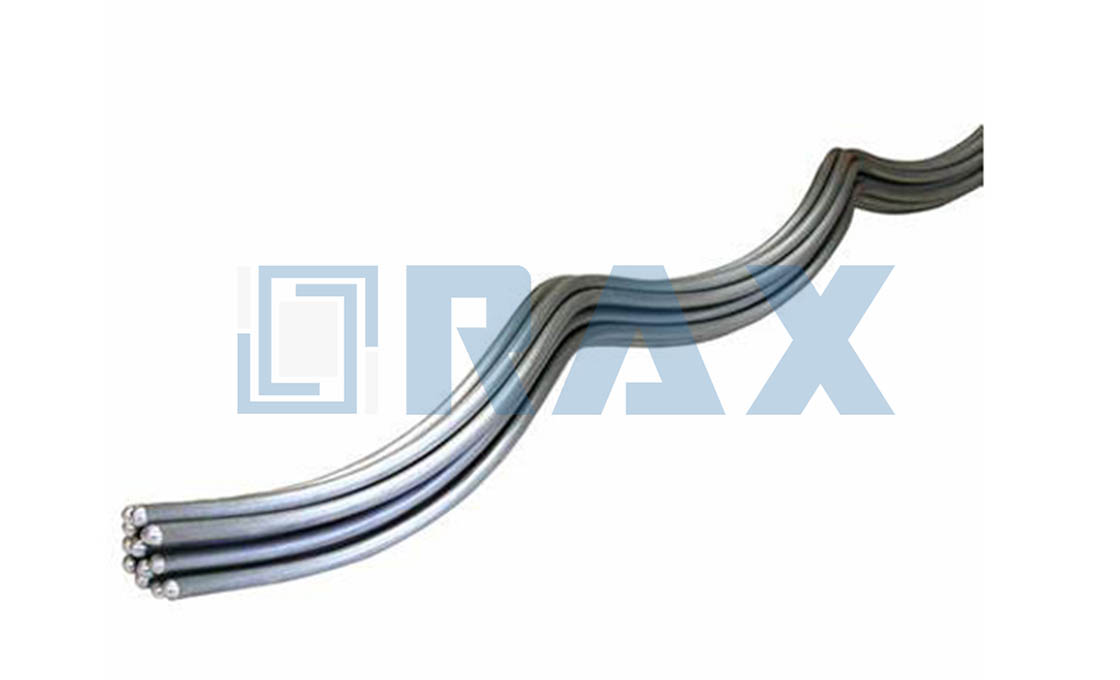

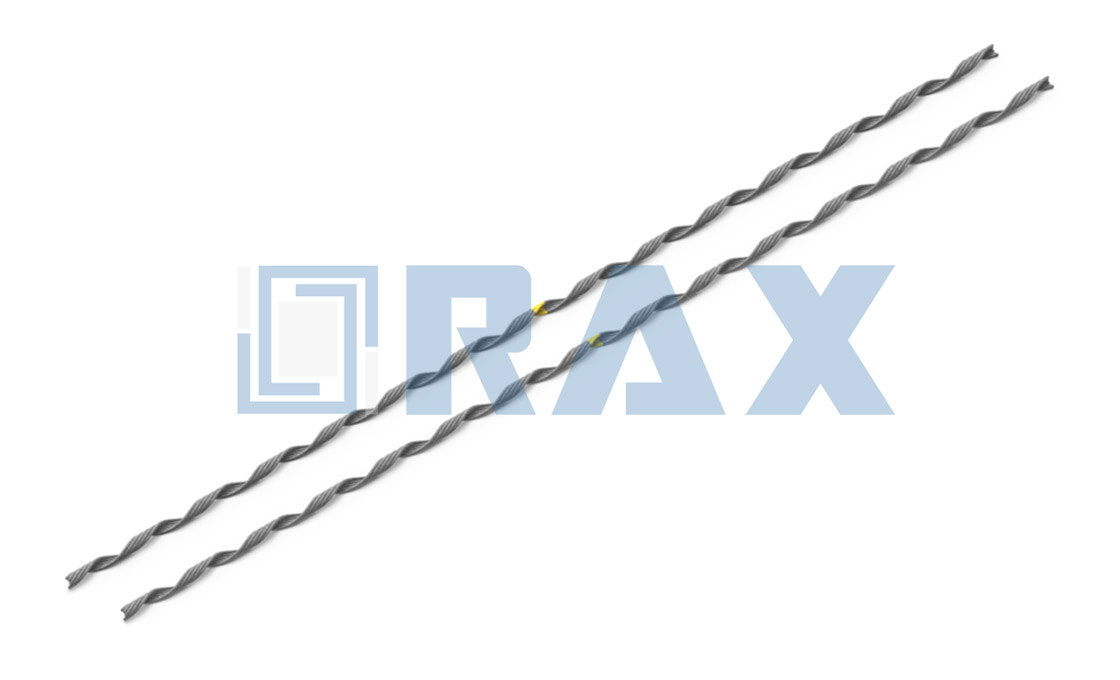

Formed Lashing Rods, also known as cable lashing rods, are essential components designed for securing messengered overhead cables. These rods are particularly effective in spans obstructed by trees or short spans over traffic intersections. They support power cables entering and exiting substations, ensuring stability and safety. Made from materials such as galvanized steel, Copperweld, aluminum-clad steel, and stainless steel types 302 and 316, the formed Lashing Rods can be customized to meet specific installation requirements. Their structure allows them to exert low radial pressure on cables, minimizing potential damage.

To use the formed Lashing Rods, position the rod close to the loop of the dead end and overlap each successive rod by one pitch length. For heavier cable-messenger assemblies or installations with significant sag angles, using two rods positioned 180° apart is recommended. The lashing rods are compatible with various lashing wire clamps and other overhead cable hardware, providing a comprehensive solution for aerial construction needs. Their adaptability and customizability make them suitable for diverse applications in telecommunications and electrical distribution.

Key Features:

- Customizable lengths and diameters for specific installation requirements

- Made from durable materials like galvanized steel and stainless steel

- Low radial pressure design to protect cables during installation

- Suitable for spans obstructed by trees or over traffic intersections

Compatible with various lashing wire clamps for enhanced security

Frequently Asked Questions (FAQ)

What are Preformed Lashing Rods?

Preformed Lashing Rods are specialized hardware used to secure messengered overhead cables. They are particularly effective in spans obstructed by trees or short spans over traffic intersections, and they support power cables into and out of substations.

What materials are Preformed Lashing Rods made from?

These rods can be made from various materials including Galvanized Steel, Copperweld, Aluminum-clad Steel, and Stainless Steel (Type 302 and Type 316). The choice of material depends on the specific application and environmental conditions.

How do I select the right size of Preformed Lashing Rod?

To select the appropriate size, determine the smallest circumscribing circle that will encompass the messenger and cables. The diameter of the rod should exert low radial pressure on the cables for optimal performance.

What are the standard sizes of Preformed Lashing Rods?

Common sizes include:

- LR-6105: 0.670″ – 0.749″

- LR-6106: 0.750″ – 0.839″

- LR-6107: 0.840″ – 0.939″

- LR-6108: 0.940″ – 1.049″

- LR-6113: 1.630″ – 1.819″

We are a leading manufacturer capable of customizing sizes based on customer requirements.

How many lashing rods should be used per installation?

For most installations, one lashing rod is recommended, overlapping one pitch length with each successive rod. If the cable-messenger assembly weighs more than eight pounds per foot or if the angle of sag exceeds 20°, two rods applied 180 degrees apart are advisable.

What is the weight capacity of Preformed Lashing Rods?

The weight capacity varies depending on the size and material of the rod. Generally, they are designed to withstand significant loads, making them suitable for various overhead cable applications. Always refer to specific product specifications for detailed load ratings.