Service Grip Dead End

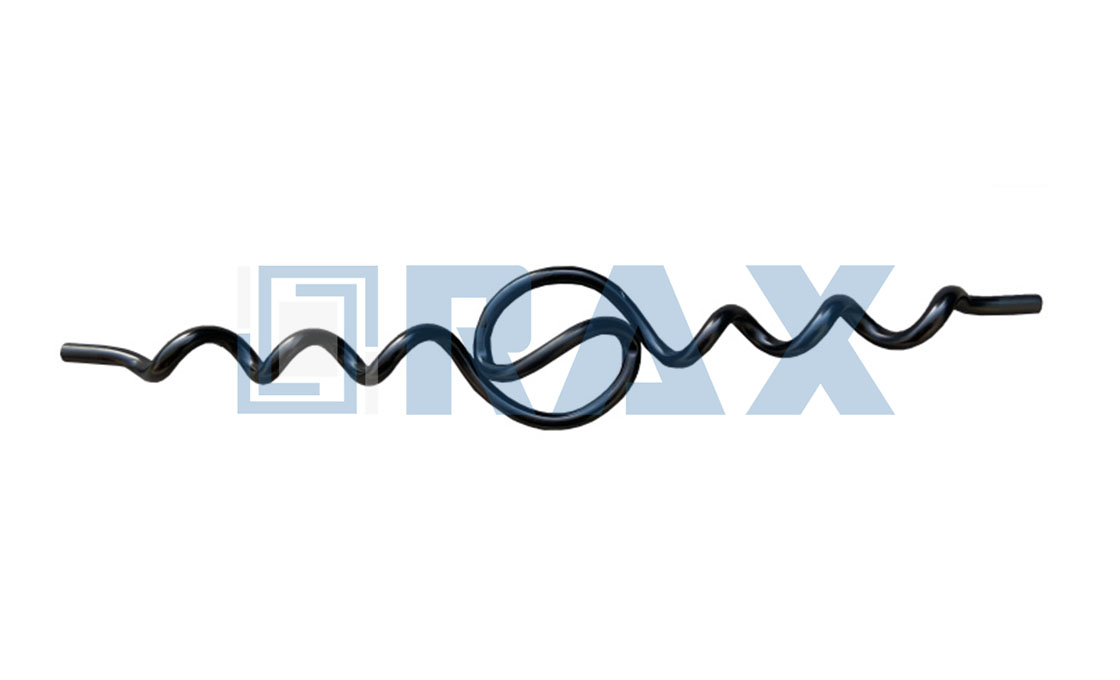

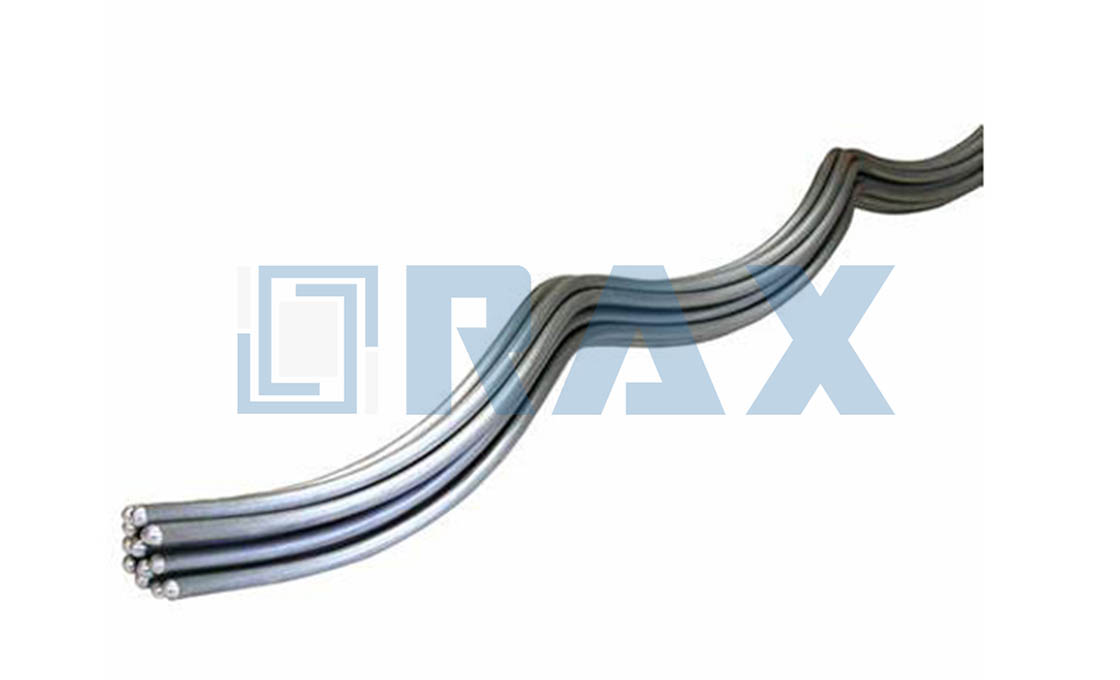

A Service Grip Dead End, also known as a Formed Wire Service Grip, is a device designed to terminate bare neutral messengers of self-supporting cable used in making service drops. The structure consists of a covered loop section with an elastomer coating, manufactured from aluminum-covered steel. Service Grip Dead Ends come in various sizes to accommodate different conductor diameters, typically ranging from 0.229″ to 1.216″.

The primary function of a Service Grip Dead End is to provide a secure and economical termination point for service drops while maintaining a neat appearance. It is specifically designed to be installed on pin, line post, or spool insulators. Service Grip Dead Ends are used in electrical distribution systems, particularly for connecting service drops to utility poles. They can be installed using hot stick applications and are compatible with various conductor types, excluding high temperature or low-sag conductors.

Features of Service Grip Dead End:

• Tool-free installation (except for hot stick applications)

• Uniform conductor grip to prevent distortion

• Meets NESC Grade “N” requirements for spans up to 150 feet

• Eliminates the need for bolts, nuts, and washers

• Suitable for bare aluminum-based conductors

• Designed for minimum length and economic efficiency

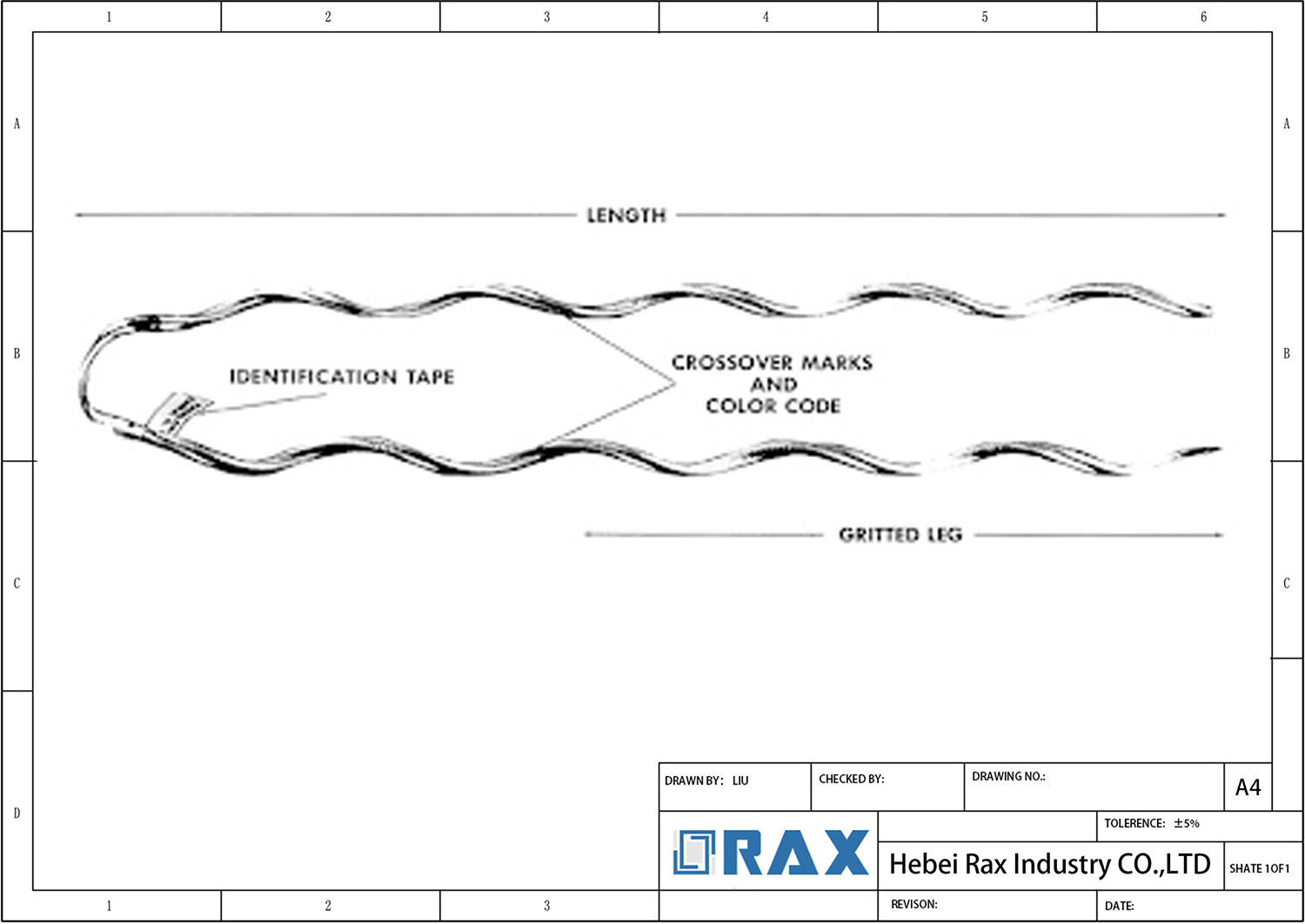

Service Grip Dead End Drawing

| Catalog Number | Diameter Range (In.) | Nominal Conductor Sizes | Units | Wt./Lbs. | Length (In.) | Color Code | Max. Neck Dia. (In.) | ||||

| Min. | Max. | ACSR | All-Alum. | Alum. Alloy | Comp. | PerC | barton | ||||

| SG-4500 | .169 | .198 | #6, 6/1 | #6, 7W | #6, 7W | #6, 6/1 #6, 7W | 300 | 24 | 11 | Blue | 2-3/8 |

| SG-4501 | .199 | .224 | #5, 6/1 | #4, Solid | #5, 7W | #4, 7W | 300 | 27 | 12 | White | 2-3/8 |

| SG-4502 | .225 | .257 | #4, 6/1 #4, 7/1 | #4, 7W | #4, 7W | #4, 6/1 #4, 7/1 | 300 | 29 | 13 | Orange | 2-3/8 |

| SG-4503 | .258 | .289 | #3, 6/1 | #3, 7W #2, Solid | #3, 7W | #3, 6/1 #2, 7W | 200 | 27 | 14 | Black | 2-5/8 |

| SG-4504 | .290 | .325 | #2, 6/1 #2, 7/1 | #2, 7W | #2, 7W | #2, 6/1 # 1,7W | 200 | 28 | 15 | Red | 2-5/8 |

| SG-4505 | .326 | .360 | # 1,6/1 | #1,7W | # 1,7W | #1, 6/1 1/0, 7W | 200 | 31 | 17 | Gree n | 2-5/8 |

| SG-4506 | .361 | .400 | 1/0, 6/1 | 1/0, 7W | 1/0, 7W | 1/0, 6/1 2/0, 7W | 100 | 28 | 19 | Yellow | 2-7/8 |

| SG-4507 | .401 | .450 | 2/0, 6/1 | 2/0, 7W | 2/0, 7W | 2/0, 6/1 3/0, 7W | 100 | 31 | 21 | Blue | 2-7/8 |

| SG-4508 | .451 | .510 | 3/0, 6/1 | 3/0, 7W | 3/0, 7W | 4/0, 7W | 100 | 33 | 23 | Orange | 2-7/8 |

| SG-4509 | .511 | .580 | 4/0, 6/1 4/0, 18/1 | 4/0, 7W | 4/0, 7W | 4/0, 6/1 | 100 | 37 | 26 | Red | 3 |

Frequently Asked Questions (FAQ)

What is a Service Grip Dead End?

A Service-Grip Dead-End is designed for bare neutral messengers of self-supporting cable used in making service drops. It’s manufactured from aluminum-covered steel and recommended for service drops due to its minimum length, economy, and neat appearance. Mechanical strength meets NESC Grade “N” requirements for spans under 150 feet.

What is its primary application?

Dead service grips are partial tension devices capable of holding at least 50% of the rated breaking strength of noted conductors. They are specifically used to dead-end neutral messengers in service drop applications and are compatible with different conductors including AAC, ACSR, and AAAC.

What are its key features?

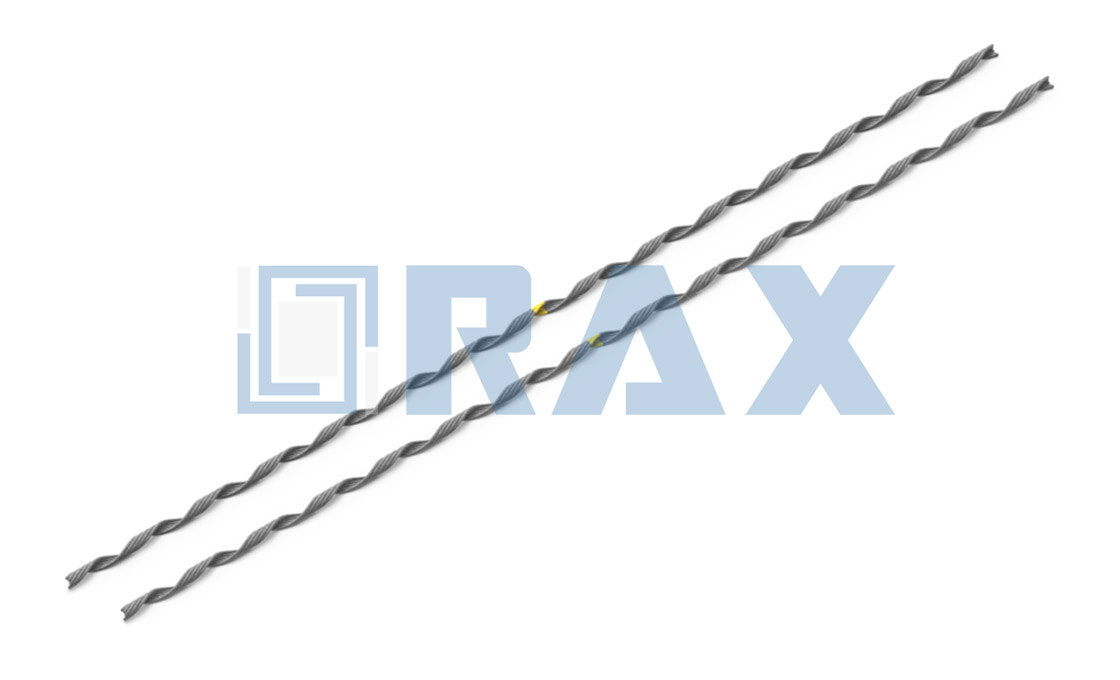

The device eliminates the need for nuts, bolts, washers, and parts that might become damaged or lost during installation. It’s made of aluminum-covered steel and features crossover marks, color coding, and identification tape for proper installation guidance.

What are the installation requirements?

Service grip dead ends should not be reused after original installation. The lay direction of both the dead end and conductor should match (typically right-hand lay for neutral messengers). The loops should not be criss-crossed when multiple units are applied to the same spool.

What type of fittings are compatible?

The loops are designed for use with porcelain fittings that have smoothly contoured diameters between 1-1/8″ minimum and 3″ maximum. Specific neck diameter requirements vary by model and should be verified before installation.

What are the tapping guidelines?

Tapping over the applied legs of Service-Grip Dead-End is not recommended. Taps should be made on the conductor ahead of the Dead-end, or the conductor can continue through the crossover point with connectors applied to the continued tail.

What about vibration considerations?

For applications where vibration is a concern, Distribution-Grip Dead-ends are recommended instead of Service-Grip Dead-ends, as no consideration for dampening devices is made with Service-Grip Dead-ends.

When should you use alternative products?

For service drops exceeding 150 feet or Grade “C” Construction, the Distribution-Grip Dead-end is recommended instead of the Service-Grip Dead-end. For plastic jacketed open-wire service drops, the coated Dead-end version is recommended.